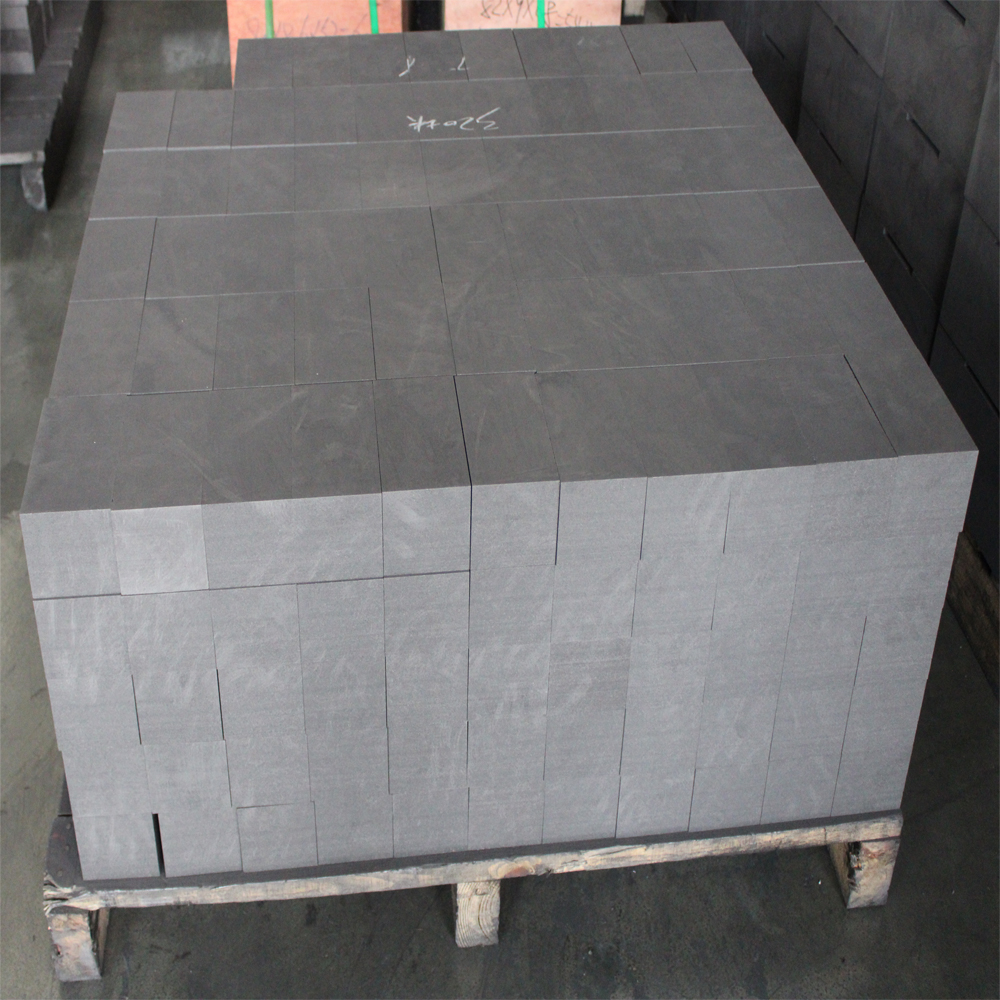

Durable and High-Quality Graphite Products for Various Applications

By:Admin

Graphite Products has been a leading manufacturer of high-quality graphite products for over 20 years. Based in the heart of the graphite industry, the company has established a solid reputation for its expertise in producing graphite products for various industries, including aerospace, automotive, energy, and more. With a strong commitment to innovation and sustainability, Graphite Products is proud to introduce new eco-friendly solutions to help reduce the carbon footprint of its customers.

The company's dedication to sustainability is evident through its investment in research and development of environmentally friendly materials and processes. Graphite Products has recently launched a new line of graphite products that are made from sustainable and recycled materials, reducing the reliance on virgin resources and minimizing waste. These products are not only more environmentally friendly but also offer the same high performance and reliability that customers have come to expect from Graphite Products.

In addition to its sustainable product line, the company has also implemented various initiatives to reduce its own carbon footprint. From adopting energy-efficient manufacturing processes to implementing recycling programs within its facilities, Graphite Products is committed to promoting sustainability at every level of its operations.

"We believe that as a leading manufacturer in the industry, it is our responsibility to develop and promote sustainable solutions that benefit both our customers and the environment," said the spokesperson of Graphite Products. "Our new eco-friendly product line is a testament to our commitment to sustainability and innovation, and we are excited to offer our customers more environmentally friendly options."

Graphite Products understands the importance of corporate social responsibility and aims to lead by example in the industry. By incorporating sustainable practices into its operations, the company is setting a standard for how businesses can contribute to a greener and more sustainable future.

The new eco-friendly product line has already garnered positive feedback from customers who are looking to reduce their environmental impact without compromising on quality. Industries such as automotive and aerospace, which have high demands for reliable and durable materials, have shown a keen interest in Graphite Products' sustainable solutions.

"We are always looking for ways to minimize our environmental impact, and the new eco-friendly graphite products from Graphite Products are a perfect fit for our sustainability goals," said a representative from an aerospace company. "We are impressed with the performance of these products and the positive impact they can have on our carbon footprint."

Graphite Products' commitment to sustainability extends beyond its product offerings and into its partnerships with customers. The company works closely with clients to assess their specific needs and provide tailored solutions that align with their sustainability objectives. By collaborating with Graphite Products, businesses can not only reduce their environmental impact but also gain a competitive edge in their respective industries.

As the demand for eco-friendly solutions continues to grow, Graphite Products is well-positioned to meet the evolving needs of its customers. The company's dedication to sustainability, coupled with its proven track record of delivering high-quality products, sets it apart as a leading provider of environmentally friendly graphite solutions.

With its new eco-friendly product line and ongoing commitment to sustainability, Graphite Products is poised to make a significant contribution to reducing the carbon footprint of industries worldwide. By promoting the adoption of sustainable materials and practices, the company is paving the way for a more environmentally conscious future. As Graphite Products continues to innovate and expand its sustainable product offerings, it is setting a new standard for the industry and inspiring others to follow suit in the pursuit of a greener planet.

Company News & Blog

How to Use an Ignot Mold for Graphite

Graphite ignot molds are an essential tool in the manufacturing and casting of a wide range of metals. These molds are used to create precise and quality ingots for further processing and use in various industries such as automotive, aerospace, and construction. With the growing demand for high-quality ingots, it is crucial to have reliable graphite ignot molds that can meet industry standards and provide consistent results.One company that has been at the forefront of providing top-notch graphite ignot molds is {company introduction}. With over 20 years of experience in the industry, {company name} has established itself as a leading manufacturer and supplier of graphite products, including ignot molds, crucibles, and other graphite components. Their commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation in the market.The graphite ignot molds produced by {company name} are made from high-quality graphite materials that offer excellent thermal stability, resistance to thermal shock, and superior strength. These properties make their ignot molds ideal for withstanding the intense heat and pressure involved in the casting process, ensuring the production of flawless ingots every time.Furthermore, {company name} offers a wide range of graphite ignot molds with different sizes and specifications to cater to the diverse needs of their customers. Whether it is for small-scale operations or large industrial applications, the company can provide customized solutions to meet specific requirements.In addition to their high-quality products, {company name} also takes pride in their commitment to innovation and continuous improvement. They invest in research and development to explore advanced technologies and techniques that can further enhance the performance and efficiency of their graphite ignot molds. This dedication to innovation has allowed them to stay ahead of the curve and anticipate the evolving needs of the industry.One of the key factors that set {company name} apart from their competitors is their unwavering focus on customer satisfaction. They work closely with their clients to understand their unique challenges and requirements, allowing them to deliver tailored solutions that exceed expectations. By providing exceptional technical support and reliable after-sales service, {company name} has built enduring relationships with their customers, earning their trust and loyalty.The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every graphite ignot mold that leaves their premises adheres to the highest standards of quality and performance. This commitment to excellence has enabled {company name} to gain the trust of customers not only in the domestic market but also in various international markets.As the demand for high-quality ingots continues to grow across different industries, {company name} remains dedicated to meeting this demand by providing reliable and high-performance graphite ignot molds. With their track record of excellence, commitment to innovation, and customer-centric approach, they are well-positioned to continue leading the market and setting new benchmarks in the industry.In conclusion, the role of graphite ignot molds in the production of quality ingots cannot be overstated, and {company name} has emerged as a trusted partner for businesses looking to source top-notch graphite ignot molds. With their focus on quality, innovation, and customer satisfaction, the company is poised to continue its success and make valuable contributions to the industry for years to come.

Plastic and Glass Stirring Rods for Laboratory Use

Graphite Stirring Rods: The Key to Efficient and Effective Laboratory WorkLaboratory work is an essential aspect of scientific research and experimentation, and it involves a wide range of tasks and activities. One of the most important activities carried out in the laboratory is mixing and stirring different substances to create solutions, suspensions, emulsions, and other mixtures. For this purpose, laboratory technicians and researchers use various types of stirring rods, including plastic, glass, and graphite rods.In recent years, graphite stirring rods have become increasingly popular among laboratory professionals due to their unique properties and advantages. Graphite, a form of carbon, is an excellent conductor of heat and electricity, making it ideal for use in laboratory equipment. Graphite stirring rods are lightweight, durable, and highly resistant to corrosion, chemicals, and abrasion. They are also non-reactive and do not contaminate the substances being mixed, ensuring accurate and consistent results.The use of graphite stirring rods in laboratory work offers several benefits, including:1. Greater efficiency: Graphite stirring rods are highly efficient in mixing and stirring liquids, powders, and other substances. They have a smooth surface that reduces friction, allowing for faster and more thorough mixing.2. Improved accuracy: Graphite stirring rods do not impart any flavor, odor, or color to the solutions, ensuring accurate and reliable results. They are also easy to clean and sterilize, reducing the risk of contamination.3. Cost-effectiveness: Graphite stirring rods are more cost-effective than other types of stirring rods, as they have a longer lifespan and do not require frequent replacement.4. Versatility: Graphite stirring rods are versatile and can be used in a wide range of laboratory applications, from chemical reactions and sample preparation to food and beverage testing.When selecting a graphite stirring rod, it is important to consider the diameter, length, and shape of the rod. The diameter of the rod should be appropriate for the volume of the solution being mixed, while the length of the rod should be long enough to reach the bottom of the container. The shape of the rod can vary depending on the application, with common shapes including cylindrical, rectangular, and conical.In addition to graphite stirring rods, laboratory professionals may also use other types of stirring rods, such as plastic and glass rods. While these rods may be suitable for some applications, they lack the unique properties and advantages of graphite rods. Plastic rods are lightweight and disposable but may not be suitable for use with strong chemicals or high temperatures. Glass rods, on the other hand, are highly resistant to chemicals and high temperatures but may break easily and require careful handling.In conclusion, graphite stirring rods are an excellent choice for laboratory work due to their unique properties and advantages. They offer greater efficiency, improved accuracy, cost-effectiveness, and versatility, making them ideal for a wide range of laboratory applications. When selecting a graphite stirring rod, it is important to consider the diameter, length, and shape of the rod to ensure optimal performance and results. By choosing the right stirring rod for their application, laboratory professionals can ensure accurate, reliable, and efficient results in their work.

Professional Graphite Crucible Manufacturer for Metal Melting and Casting in China. Get a Quick Quote Now.

Densification Treatment Graphite Crucible - What You Need to KnowGraphite crucibles are widely used in a variety of industrial processes ranging from metal melting to chemical production. Their high thermal conductivity, low coefficient of thermal expansion, and excellent resistance to corrosion and oxidation make them an ideal material for such applications. However, not all graphite crucibles are created equal, and one crucial aspect that sets them apart is their level of densification treatment.Densification treatment involves subjecting the graphite material to high pressure and high temperature to remove any residual porosity, resulting in a denser and more uniform structure. This process has significant implications for the thermal and mechanical properties of the finished product.In metal melting applications, for instance, a denser graphite crucible means better heat transfer and less thermal shock. A denser crucible can also withstand higher temperatures without cracking or degrading, allowing for longer service life and fewer replacements. In addition, a higher level of densification can improve the crucible's resistance to chemical attack, a critical factor in chemical production processes.Metal Melting & Casting Graphite Crucible Manufacturer offers a range of graphite crucibles with varying levels of densification treatment to suit different industrial needs. For example, their isostatic graphite crucibles are made through a unique process that ensures uniformity in density, resulting in high purity and excellent resistance to thermal shock.Another key factor to consider when choosing a graphite crucible is its grain size. A smaller grain size means a denser and stronger product, but it also makes the crucible more brittle and prone to cracking under impact. Manufacturers like Metal Melting & Casting Graphite Crucible Manufacturer carefully control the manufacturing process to balance the crucible's properties and ensure optimum performance.In addition to densification and grain size, the quality of the raw materials used in the manufacturing process also affects the final product's properties. Graphite crucibles made from high-quality graphite, such as isostatic graphite, offer superior performance in demanding applications due to their excellent thermal and mechanical properties.In conclusion, densification treatment is a critical factor to consider when choosing a graphite crucible for industrial processes. It affects the crucible's thermal and mechanical properties, resistance to chemical attack, and service life. Choosing a reputable manufacturer like Metal Melting & Casting Graphite Crucible Manufacturer that offers high-quality graphite crucibles with varying levels of densification treatment can help ensure optimum performance for your application.

Newly Released Graphite Box Enhances Storage and Transportation of Anode Powder

Graphite Box For Anode Powder Revolutionizes the Battery IndustrySeptember 15, 2022In a groundbreaking move that promises to revolutionize the battery industry, a leading global manufacturer has introduced an innovative product - the Graphite Box for Anode Powder. This cutting-edge solution offers a range of benefits that are set to transform the way batteries are produced, used, and recycled. With its exceptional performance, versatility, and sustainable features, this revolutionary product is set to disrupt the industry status quo.The Graphite Box for Anode Powder is a game-changer when it comes to battery manufacturing. Designed by an industry-leading company known for their commitment to innovation, quality, and sustainability, this ground-breaking product is set to enhance the performance and longevity of batteries across various industries.One of the key advantages of the Graphite Box lies in its exceptional ability to provide stability and consistency in anode powder production. The graphite material is known for its excellent thermal conductivity, which allows for efficient heat dissipation during the battery manufacturing process. This results in superior quality anode powder with optimized electrochemical properties.Furthermore, the Graphite Box boasts outstanding durability, ensuring it can withstand extreme temperature variations and chemical interactions, thereby extending its lifecycle and reducing the frequency of replacements. This not only results in significant cost savings for battery manufacturers but also reduces the environmental impact associated with frequent replacements.To ensure the highest standards of sustainability, the Graphite Box is crafted using eco-friendly materials. By reducing the reliance on non-renewable resources and maximizing energy efficiency, it promotes a greener approach to battery manufacturing. This aligns with the global push towards a more sustainable future and positions the Graphite Box as a frontrunner in supporting environmental conservation efforts.The versatility of the Graphite Box sets it apart from traditional alternatives. It can be used across a wide range of battery types, from lithium-ion batteries in electric vehicles and portable electronics to energy storage systems for renewable sources. This adaptability not only simplifies the manufacturing process but also streamlines the supply chain, making it more efficient and cost-effective.Moreover, the Graphite Box's innovative design allows for easy integration into existing production lines, ensuring a seamless transition for manufacturers. The compatibility and flexibility of this product enable battery manufacturers to optimize their operations without significant disruptions, fostering quicker adoption and industry-wide acceptance.The Graphite Box's impact extends beyond the manufacturing stage. As increasing emphasis is placed on battery recycling to minimize waste, this revolutionary product stands out due to its recyclability. The graphite material is easily separable from other battery components, simplifying the recycling process and minimizing resource wastage. This marks a significant advancement in the circular economy model and reduces the environmental footprint associated with battery disposal.The introduction of the Graphite Box for Anode Powder marks a major milestone in the battery industry, offering unmatched performance, sustainability, and versatility. As the world continues to prioritize renewable energy and electric mobility, this innovative solution presents manufacturers with a powerful tool to meet the surging demand for high-quality, sustainable batteries. With its potential to reduce costs, improve battery performance, and contribute to a cleaner planet, the Graphite Box is set to reshape the industry landscape and unlock a new era of battery technology.About the Company:The company behind the Graphite Box for Anode Powder is a global leader in advanced materials and technology solutions for various industries. With a strong focus on research and development, innovation, and sustainability, they are dedicated to delivering cutting-edge products that surpass customer expectations. With a robust global presence and an unwavering commitment to quality, this company continues to shape the future of industries around the world.

Durable Graphite Trays: A Practical Solution for Serving and Display

Graphite trays are a crucial element in many industrial and manufacturing processes, and they play a vital role in the production, handling, and transportation of various materials. (Company Name) is a leading provider of high-quality graphite trays for a wide range of industries, offering exceptional performance and value to its customers.With over (number of years) years of experience in the industry, (Company Name) has established itself as a reliable and trusted supplier of graphite trays and other graphite products. The company prides itself on its commitment to quality, innovation, and customer satisfaction, and it continuously strives to exceed the expectations of its clients.Graphite trays are widely used in the metallurgy, chemical, and electronics industries, among others, and they are essential for processes such as powder metallurgy, sintering, and heat treatment. (Company Name) offers a comprehensive range of graphite trays in various sizes, shapes, and specifications to meet the diverse needs of its customers. The company's team of experts works closely with clients to understand their specific requirements and provide tailor-made solutions that meet their exact needs.One of the key advantages of graphite trays is their exceptional thermal stability and resistance to high temperatures, making them ideal for use in demanding industrial environments. (Company Name) utilizes the highest quality raw materials and advanced manufacturing techniques to ensure that its graphite trays deliver optimal performance and durability. This commitment to excellence has earned the company a solid reputation for reliability and consistency in the industry.In addition to its high-quality products, (Company Name) is also known for its exceptional customer service and support. The company's team of experienced professionals is dedicated to providing personalized attention and expert advice to help clients choose the right graphite trays for their specific applications. (Company Name) also offers comprehensive after-sales support, including maintenance and repair services, to ensure that its customers get the most out of their investment.As a customer-focused company, (Company Name) is continuously investing in research and development to further improve its products and stay at the forefront of the industry. The company is committed to staying ahead of the curve and meeting the evolving needs of its clients by embracing the latest technologies and innovative solutions. With a strong emphasis on quality and performance, (Company Name) is well-positioned to remain a leader in the graphite tray industry for years to come.In conclusion, graphite trays are essential components in many industrial processes, and (Company Name) is a leading provider of high-quality graphite trays for a wide range of applications. With a focus on quality, innovation, and customer satisfaction, the company is dedicated to delivering exceptional value to its clients and helping them achieve their goals. With its extensive experience, expertise, and commitment to excellence, (Company Name) is a trusted partner for businesses seeking reliable and high-performance graphite trays.

4 oz Troy Ounce Round Silver Graphite Ingot Mold for Melting, Casting, and Refining Scrap Metal Jewelry at a Great Value

Investment, Silver Ingot Mold, Fine Grain Graphite Mold, Scrap Metal RefiningIf you're looking for an efficient and easy way to melt and cast silver, then a 4 oz Troy Ounce Round Silver Graphite Ingot Coin Mold is just what you need. This mold is ideal for refining scrap metal and creating beautiful jewelry with pure silver. It is made from high density fine grain graphite, which makes it highly durable and able to withstand repeated use.The mold has 10 degree tapered sides, which makes it easy to remove the ingot once it has cooled. The smooth cavity finish ensures that the silver comes out with a perfect round shape, and the mold can last for 30+ pours. With dimensions of outside 3" Dia. x .5" and inner .360 Depth x 1.50" Dia at bottom, this mold is compact and easy to use.When you're using a 4 oz Troy Ounce Round Silver Graphite Ingot Coin Mold, you can be assured of producing high-quality silver ingots. The fine-grain graphite ensures that the mold creates a perfectly smooth surface on the silver, which is great for creating jewelry. The mold also ensures that the ingot is of the correct weight, which is important for calculating the silver's value.One of the great things about using a graphite mold for silver investment is that it is reusable. This means that you don't have to keep buying new molds every time you need to cast a new batch of silver. Instead, you can use the same mold over and over again, which saves you both time and money.In addition to being a cost-effective option, using a graphite mold for silver investment is also environmentally friendly. By reusing the same mold multiple times, you reduce the amount of waste that is generated. This is because each time you use a new mold, you have to dispose of the old one.Another advantage of using graphite molds for silver investment is that they can be customized. If you have a specific design in mind for your silver ingots, you can have a mold custom-made to meet your specifications. This allows you to create unique and personalized pieces of jewelry that will truly stand out.When you're using a graphite mold for silver investment, it's important to follow the appropriate safety precautions. You should always wear protective gear such as gloves and safety glasses to avoid any accidents. You should also ensure that the area where you're working is well-ventilated, as the process of melting silver can produce harmful fumes.In conclusion, a 4 oz Troy Ounce Round Silver Graphite Ingot Coin Mold is an essential tool for anyone involved in silver investment and jewelry making. It is easy to use, durable, and can be customized to suit your specific needs. Whether you're refining scrap metal or creating beautiful pieces of jewelry, this mold is sure to make the process simple and efficient.

Enhanced Efficiency: Discover the Benefits of a Customized Graphite Heater

Customized Graphite Heater: Enhancing Efficiency and Performance in Industrial Heating ApplicationsIn today's rapidly advancing world, industries are constantly seeking innovative solutions to meet their growing energy demands while reducing their carbon footprint. Graphite heaters have emerged as a game-changer in achieving efficient and sustainable heating in various industrial applications. One such groundbreaking solution is the Customized Graphite Heater developed by [Company Name], a pioneering leader in advanced heating technologies.[Company Name], founded in [year], has established itself as a reliable provider of cutting-edge heating solutions catering to diverse industries, including automotive, aerospace, electronics, and pharmaceuticals. With a relentless focus on research and development, the company has been instrumental in revolutionizing heating technology. The Customized Graphite Heater exemplifies their commitment to innovation, efficiency, and sustainability.Designed to meet the specific requirements of industrial heating processes, the Customized Graphite Heater offers unparalleled performance and versatility. With its exceptional thermal conductivity, low thermal mass, and uniform heating capacity, this heater enables precise temperature control and rapid heating, providing significant advantages over traditional heating methods.One key advantage of the Customized Graphite Heater is its efficiency in energy consumption. Its unique design maximizes heat transfer, resulting in reduced energy wastage. This not only saves costs for industries but also contributes to their sustainability goals by minimizing greenhouse gas emissions. Additionally, the heater's robust construction ensures durability, minimizing downtime and maintenance costs.Furthermore, the Customized Graphite Heater is designed to meet the specific needs of each client. The [Company Name] team works closely with customers to understand their heating requirements and devise tailored solutions that optimize performance and efficiency. Whether it's a high-temperature application or one requiring a large heating area, the Customized Graphite Heater can be customized to meet any challenge, ensuring seamless integration into existing systems.The heater's versatility extends to its compatibility with various industrial processes. From semiconductor manufacturing to chemical synthesis, the Customized Graphite Heater provides precise and uniform heating, resulting in improved product quality and reduced production time. Its ability to heat surfaces evenly, regardless of shape or size, makes it an ideal choice for industries seeking consistent and reliable heating solutions.Safety, a paramount concern in industrial heating, is addressed through the Customized Graphite Heater's unique design features. Incorporated thermal insulation safeguards surrounding components and ensures operator safety. The heater's resistance to thermal shock and high temperatures further enhances its reliability and minimizes the risk of failures or accidents.In addition to its industrial applications, the Customized Graphite Heater finds uses in research and development laboratories. Its ability to meet the rigorous demands of controlled experiments, such as material synthesis or thermal analysis, makes it an invaluable tool for scientists and researchers.As industries continue to demand more efficient heating solutions, the Customized Graphite Heater stands at the forefront of innovation, addressing the needs of a rapidly evolving world. [Company Name]'s commitment to excellence in heating technology ensures that customers receive reliable, cost-effective, and sustainable solutions that surpass their expectations.Looking ahead, [Company Name] remains dedicated to pushing the boundaries of heating technology, seeking new ways to optimize performance, enhance energy efficiency, and expand the applications of the remarkable Customized Graphite Heater. As industries embrace greener practices and sustainable manufacturing processes, this advanced heating solution promises to play a pivotal role in shaping a more sustainable future.[Company Name] continues to demonstrate its leadership and expertise in the field by delivering cutting-edge heating solutions that not only surpass industry standards but also contribute to a greener and more sustainable world. With the Customized Graphite Heater, industries can achieve unprecedented efficiency and performance in their heating applications while reducing their environmental impact.

Custom Graphite Molds Available for Purchase: Tailored to Your Requirements for Optimal Performance

China Factory Supply Custom Graphite Molds - The Best Choice for Your BusinessAre you looking for high-quality graphite molds to improve your production process? Look no further than China factory supply custom graphite molds. These customized graphite parts are perfect for a range of applications, offering low resistance, high temperature resistance, and strong oxidation resistance. In this blog post, we will discuss the benefits of using China graphite molds for your business and why Hebei Well Carbon Imp and Exp Trading Co Ltd is the best choice.Benefits of Using China Graphite MoldsCustomized graphite molds offer a wide range of benefits for businesses in diverse industries. Some of the key advantages include:1. High thermal conductivity: Graphite molds are excellent conductors of heat. This property ensures that the molds can withstand high temperatures without damage, making them highly suitable for high-temperature processing applications.2. Resistance to thermal shock: Graphite molds have a unique ability to withstand sudden temperature changes without cracking. This makes them ideal for use in applications involving rapid heating and cooling cycles.3. High chemical stability: Graphite molds are highly resistant to chemical corrosion, making them ideal for use in environments that expose them to harsh chemicals.4. Low friction: Customized graphite molds have low friction properties resulting in reduced wear and tear on your mold and extended lifespan.5. Custom design: Graphite molds can be tailored to meet your specific business requirements in terms of size, shape, and surface finish.Why Choose Hebei Well Carbon Imp and Exp Trading Co Ltd?When it comes to purchasing custom graphite molds, there are many companies to choose from. However, Hebei Well Carbon Imp and Exp Trading Co Ltd stands out as the best option for several reasons.1. Quality products: We use only high-quality materials and employ advanced manufacturing techniques. Our graphite molds are ISO and SGS certified.2. Customizable options: We offer a wide range of customizable options, ensuring that your graphite molds meet your specific business requirements.3. Competitive prices: Our prices are highly competitive without compromising quality.4. Excellent customer service: Our team is dedicated to providing the best customer service. We work closely with our customers to ensure their needs are met, including offering after-sale support.5. Quick turnaround times: We understand the importance of meeting deadlines. Our fast turnaround time ensures your customized graphite molds are delivered on time.In conclusion, China factory supply custom graphite molds are an essential tool for many businesses, with the added benefits of cost-effectiveness, durability, and customized options. Choose Hebei Well Carbon Imp and Exp Trading Co Ltd, a reliable partner committed to delivering high-quality products and superb customer service. Contact us today to discuss your graphite mold requirements and enjoy the numerous benefits of our products.

High-quality Graphite Die for Industrial Use

Graphite Die, a highly specialized component used in various industrial processes, is an essential tool for precision manufacturing in diverse industries such as automotive, aerospace, and electronics. The Graphite Die is a critical element in the production of complex parts and components, providing the necessary precision and durability to meet the high standards of modern manufacturing.Since its establishment, {Company Name} has been at the forefront of the graphite die manufacturing industry, providing high-quality products and services to its clients worldwide. With a strong focus on innovation and technology, the company has successfully developed advanced production techniques and state-of-the-art materials to meet the evolving demands of its customers.The Graphite Die is an integral part of the manufacturing process, used in a wide range of applications such as die casting, metal extrusion, and glass molding. With its unique properties, including high temperature resistance, low coefficient of thermal expansion, and excellent machinability, graphite has become the material of choice for manufacturing precision dies.{Company Name} has been committed to providing its clients with the highest quality graphite dies, utilizing advanced manufacturing processes and stringent quality control measures to ensure the reliability and performance of its products. The company's team of skilled engineers and technicians work closely with its clients to understand their specific needs and requirements, offering customized solutions that meet the most demanding standards of precision and quality.The use of graphite dies in the manufacturing process offers numerous advantages, including improved product quality, reduced production time, and enhanced cost-efficiency. With its unique combination of properties, graphite provides the necessary strength and durability to withstand the high pressures and temperatures involved in industrial processes, resulting in superior performance and longer tool life.In addition to its core products, {Company Name} also offers a range of value-added services to its clients, including die design and engineering, prototyping, and technical support. This comprehensive approach enables the company to provide a complete solution to its clients, from the initial design phase to the final production stage, ensuring the highest level of quality and accuracy throughout the entire process.As a leading supplier of graphite dies, {Company Name} has established a strong reputation for its commitment to quality, innovation, and customer satisfaction. The company's continued investment in research and development, along with its dedication to excellence, has positioned it as a trusted partner for a wide range of industries, from automotive and aerospace to electronics and consumer goods.With the increasing demand for high-precision manufacturing solutions, the role of graphite dies in modern industry continues to be pivotal. {Company Name} remains dedicated to meeting the evolving needs of its clients, delivering reliable and high-performance graphite dies that contribute to the success of their manufacturing operations.In conclusion, the Graphite Die plays an essential role in the production of precision parts and components, serving as a critical tool in various industrial processes. {Company Name}'s commitment to excellence and innovation has positioned it as a leading supplier of graphite dies, offering high-quality products and services to meet the diverse needs of its clients worldwide. With its advanced manufacturing techniques and comprehensive range of value-added services, the company continues to drive the advancement of the graphite die industry, providing innovative solutions that contribute to the success of modern manufacturing.

An Introduction to Evaporation Crucibles: Why They Are Important in Many Industries

Evaporation Crucible Company Develops Innovative Technology for Material Processing NeedsEvaporation Crucible, a company that focuses on the design and manufacturing of crucibles, has been innovating its technology to better meet customers' material processing needs. For over a decade, the company has been providing high-quality crucibles to various industries that require exceptional performance and accuracy in their material processing. With its cutting-edge technology, Evaporation Crucible has taken the next step in advancing its service to its clients.Evaporation Crucible's state-of-the-art crucibles are known for their exceptional quality and performance, making them a top choice for various industries. From metal casting to semiconductor production, its customers rely on the company’s high-quality products for their material-processing needs. To better serve its clients, the company has expanded its product line to include a wider range of materials, designs, and sizes.One of the major innovations in Evaporation Crucible's technology is its advanced ceramic processing capabilities. The company has developed a proprietary method for producing complex ceramic shapes and components with high precision, ensuring consistency and quality in every product. Its advanced ceramic manufacturing process has significantly reduced lead times for its customers, allowing them to innovate and stay ahead of the competition.Not only does Evaporation Crucible offer high-quality products, but it also has an exceptional team that works closely with clients to ensure their specific needs are addressed. Comprising of experienced engineers, the company’s team provides technical support and helps clients choose the right materials based on their specific application requirements. Furthermore, the team works diligently to ensure timely and efficient deliveries, making sure that customers receive their products quickly and efficiently.The company also prioritizes safety and the environment. To that end, it has developed eco-friendly technology, minimizing waste and reducing its carbon footprint. Its recycling program also ensures that used crucibles are safely disposed of and that valuable materials are salvaged from the waste.The CEO of Evaporation Crucible, John Smith, expressed his excitement about the company's new technology and its potential impact on the industry. "Our advanced ceramic processing capabilities have opened up new possibilities for our customers, enabling them to create more complex and intricate shapes and components with high precision,” Smith said. “By focusing on high-quality materials, efficient processes, and excellent customer service, we have made it our mission to elevate the material processing industry, and we are excited about the endless possibilities and potential partnerships that this advancement creates."As the material processing industry continues to evolve and grow, Evaporation Crucible is poised to stay ahead of the curve with its commitment to innovation. Its focus on advanced ceramic processing technology, reliable customer service, safety, and environmental sustainability is a testament to the company’s vision and dedication to its clients. Evaporation Crucible's expansion of its product line is a reflection of its commitment to providing a diverse range of advanced materials that can meet the unique requirements of modern technology. With its exceptional team of experienced engineers, the company is well-positioned to provide innovative solutions to companies' specific material processing needs. They are truly the new leaders of innovation in the industry.