- Home

- Blog

- Durable Graphite Boat for Square Applications Rises in Popularity: Market Insights and Analysis

Durable Graphite Boat for Square Applications Rises in Popularity: Market Insights and Analysis

By:Admin

Introduction:

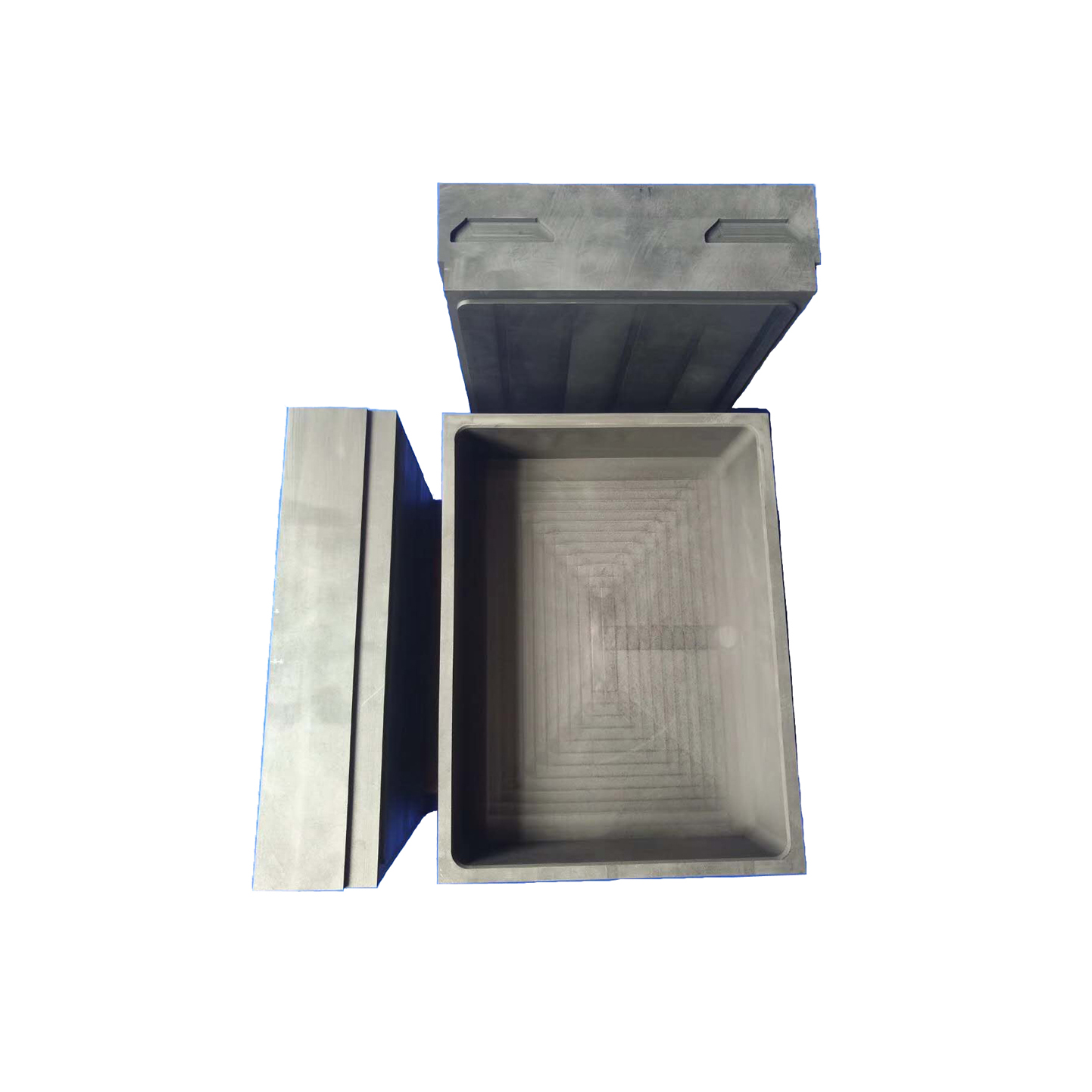

Graphite, a versatile and durable material known for its excellent thermal and electrical conductivity, has taken center stage in various industrial applications. Amongst the leaders in graphite manufacturing, a renowned company has recently unveiled their cutting-edge Square Graphite Boat - a breakthrough product that is revolutionizing multiple industries. With a commitment to innovation and an unwavering focus on quality, this new graphite boat is set to address the needs of diverse sectors and contribute to their growth.

1. The Versatility of Graphite:

Graphite, an allotrope of carbon, is highly valued for its unique properties, making it indispensable in numerous industries. It is widely used in manufacturing electrical products, semiconductors, batteries, fuel cells, and even in the aerospace industry due to its lightweight nature. The thermal stability and corrosion resistance of graphite also make it an ideal material for use in high-temperature furnaces, crucibles, and electrodes. Recognizing the potential of graphite, this pioneering company has introduced the Square Graphite Boat to enhance industrial processes across sectors.

2. The Key Features of Square Graphite Boat:

The Square Graphite Boat boasts several noteworthy features, making it stand out in the market. First and foremost, its impeccable design ensures uniform heat distribution, reducing the possibility of thermal stress cracks during high-temperature applications. The boat's superior thermal conductivity guarantees efficient heat transfer, resulting in enhanced productivity and reduced energy consumption. Furthermore, the boat's high-density graphite composition coupled with its exceptional machinability allows for intricate and precise customization, catering to the unique requirements of different industrial applications.

3. Revolutionary Applications of Square Graphite Boat:

(a) Semiconductor Manufacturing Sector:

In the semiconductor industry, where precision and reliability are paramount, the high-purity graphite material of the Square Graphite Boat proves to be indispensable. Used as a critical component in thermal processes, this boat ensures optimal heat distribution, preventing defects in the delicate semiconductor wafers. The boat's longevity and resistance to chemical reactions make it a sustainable and cost-effective solution.

(b) Energy Storage and Microelectronics Industry:

With the rapid advancement in the development of energy storage devices such as lithium-ion batteries and fuel cells, the demand for quality graphite boats has surged. The Square Graphite Boat, with its excellent electrical conductivity, corrosion resistance, and uniform heat distribution, ensures the efficient functioning and extended lifespan of these energy storage devices, consequently benefiting the electric vehicle and renewable energy sectors.

(c) Metallurgical and Chemical Industries:

Graphite boats find their application in high-temperature processes like smelting and refining metals due to their superb thermal resistance. The Square Graphite Boat, thanks to its seamless design and superior thermal conductivity, optimizes these processes by reducing energy loss and enhancing heat transfer efficiency. Its chemical stability further ensures a clean, contaminant-free environment, making it invaluable in controlled chemical reactions and laboratory settings.

4. Commitment to Quality and Sustainability:

The company behind the Square Graphite Boat is committed to producing high-quality, sustainable products. They adhere to stringent quality control measures, ensuring that every boat manufactured meets industry standards and customer specifications. Additionally, their responsible sourcing practices guarantee the usage of eco-friendly materials, minimizing the environmental impact.

Conclusion:

The Square Graphite Boat represents a significant technological milestone in the graphite industry, addressing the evolving needs of diverse sectors. Its impeccable design, high thermal conductivity, and resistance to thermal stress cracks make it an indispensable tool in various high-temperature industrial processes. The versatile applications of this boat, from semiconductor manufacturing to energy storage and metallurgical industries, highlight its immense potential. With a strong focus on quality and sustainable practices, the company behind this innovative product is steadfastly contributing to the growth and development of industries around the globe.

Company News & Blog

Discover the Benefits and Applications of Graphite Sintering Moulds

Title: Groundbreaking Graphite Sintering Mould Innovates Industrial ManufacturingIntroduction:In a significant stride towards revolutionizing industrial manufacturing processes, a cutting-edge technology has emerged - the Graphite Sintering Mould, created by an innovative company. This groundbreaking advancement holds the potential to transform various industries by providing more efficient and cost-effective solutions for producing high-quality goods. By combining the advantages of graphite as a material with ingenious mold designs, this pioneering technology is set to redefine the future of manufacturing.(Graphite Sintering Mould) – A Game-Changing Technology:(Graphite Sintering Mould) is an advanced manufacturing tool that utilizes graphite as the primary material in its mold construction. Graphite, renowned for its exceptional properties such as high thermal conductivity, low thermal expansion, and resistance to chemical corrosion, proves to be an ideal material for creating molds. The unique combination of these characteristics sets the stage for accelerating the industrial manufacturing process.(Graphite Sintering Mould) excels in a wide range of applications, including automotive, aerospace, electronics, and more. Traditionally, manufacturing processes involve the use of metal molds, which are expensive, time-consuming to produce, and have limited lifespans. However, Graphite Sintering Mould overcomes these limitations by offering unparalleled advantages.Elevating Manufacturing Efficiency:An essential aspect of (Graphite Sintering Mould) is its distinctive mold design, tailored to specific production requirements. This technology enables the production of molds with intricate shapes, precise dimensions, and excellent heat transfer capabilities. Compared to traditional molds, the use of Graphite Sintering Mould significantly reduces the cycle time, resulting in increased production efficiency and cost savings.(Graphite Sintering Mould) molds possess superior thermal conductivity, ensuring uniform heat distribution during the manufacturing process. This feature eliminates hotspots and minimizes thermal stress, thereby enhancing the overall quality and consistency of the finished products. Manufacturers can now achieve higher precision, reduced waste, and greater control over the manufacturing process, resulting in enhanced customer satisfaction.Environmental-Friendly and Cost-Effective Solution:(Graphite Sintering Mould) also offers environmental advantages by minimizing energy consumption and material waste. The high thermal conductivity of graphite enables faster heating and cooling cycles, reducing power requirements and improving energy efficiency. Additionally, the durability and longevity of (Graphite Sintering Mould) molds enable companies to produce a significantly larger number of items, thus reducing the need for frequent mold replacements.Moreover, the reduced production time and enhanced efficiency provided by (Graphite Sintering Mould) molds translate into significant cost savings for manufacturers. Companies can allocate their resources more strategically, invest in research and development, and explore new market opportunities.Emerging as a Pioneer in Industrial Manufacturing:The company behind the development of (Graphite Sintering Mould) stands at the forefront of innovation in the industrial manufacturing sector. Through extensive research and development, the company has successfully harnessed the unique properties of graphite and perfected the technology to produce reliable, high-performance molds.The exceptional quality of molds generated using (Graphite Sintering Mould) has garnered attention from major industries worldwide. Their commitment to sustainable practices alongside their relentless pursuit of excellence positions the company as a leading pioneer in the manufacturing field.Looking Forward:The introduction of (Graphite Sintering Mould) marks a significant milestone in the evolution of industrial manufacturing. With its ability to enhance production efficiency, reduce costs, and deliver superior quality products, this technology holds vast potential for various sectors. Manufacturers across the globe are eagerly adopting this groundbreaking method, propelling the industry toward a more sustainable and efficient future.As researchers continue to refine and expand the capabilities of (Graphite Sintering Mould), we can anticipate further advancements that will revolutionize the way products are manufactured. With improved mold designs, expanded applications, and increased efficiency, the possibilities for innovation with this game-changing technology are limitless.

Versatile Graphite Crucibles for Efficient Metal Melting

Gold And Silver Graphite Crucibles: Superior Quality and Performance for Your Melting NeedsChoosing the right crucible is important if you want to achieve accurate, reliable, and consistent results in your melting process. Whether you are a jeweler, a metalworker, or a manufacturer, you need a crucible that can withstand high temperatures, resist corrosive materials, and conduct heat effectively. Gold and silver graphite crucibles are ideal for melting precious metals because they offer superior quality and performance compared to other types of crucibles.One of the main advantages of graphite crucibles is their ability to withstand extreme temperatures without cracking or deforming. They can handle temperatures up to 3000°C, which makes them suitable for melting gold, silver, and other high-melting-point metals. Graphite crucibles also have excellent thermal conductivity, which means they transfer heat quickly and evenly throughout the material. This ensures that the metal melts evenly, reducing the risk of hotspots and uneven melting.Another advantage of graphite crucibles is their resistance to chemical corrosion. Graphite is inert and does not react with most acids, bases, or molten metals. This means that your crucible will not contaminate your metal with impurities or alter its properties. Plus, graphite crucibles are easy to clean and maintain, ensuring longevity and durability.When it comes to melting gold and silver, precision and accuracy are crucial. Graphite crucibles offer both. They are designed to provide consistent performance and precise temperature control, ensuring that your metal melts at the right temperature and time. This results in high-quality castings that meet your exact specifications.At (brand name removed), we offer a wide range of gold and silver graphite crucibles to meet your melting needs. Our crucibles are made from high-purity graphite and are designed for optimal performance. We also offer custom-made crucibles to fit your specific requirements. Our graphite crucibles come in various sizes and shapes, such as tapers, cylinders, and cones, and we can also provide crucibles with lids or without, depending on your preferences.Our graphite crucibles are carefully crafted to ensure quality and durability. We use advanced manufacturing techniques and quality control procedures to ensure that each crucible meets our rigorous standards. Our crucibles are lightweight and easy to handle, making them ideal for industrial and laboratory applications.In conclusion, gold and silver graphite crucibles offer a range of advantages over other types of crucibles. They are durable, heat-resistant, corrosion-resistant, and offer precise temperature control. They are ideal for melting high-melting-point metals such as gold and silver and produce high-quality castings. At (brand name removed), we provide superior-quality graphite crucibles that will meet your melting needs. Contact us today to learn more about our products and how they can improve your melting performance.

8mm Graphite Rod Used in Various Industries for Its Exceptional Strength

Title: Advancements in Graphite Rod Technology Set to Revolutionize Various IndustriesIntroduction:Graphite rods have long been recognized as vital components in numerous industrial applications, offering enhanced strength, electrical conductivity, and resistance to high temperatures. XYZ Corporation, renowned for its cutting-edge research and development, has unveiled its groundbreaking 8mm Graphite Rod. This revolutionary product promises to transform industries, such as aerospace, automotive, electronics, and renewable energy, with its exceptional quality, performance, and durability.Paragraph 1:The aerospace industry, well-known for its stringent demands on materials, is set to benefit greatly from XYZ Corporation's innovative 8mm Graphite Rod. The strength-to-weight ratio of this advanced material is unparalleled, making it ideal for constructing lightweight yet robust aircraft components. The aerospace sector can anticipate increased fuel efficiency and reduced carbon emissions, as the incorporation of these graphite rods into aircraft structures will enable manufacturers to design more aerodynamic and fuel-efficient planes.Paragraph 2:In the automotive industry, where energy efficiency and sustainability are paramount, the XYZ Corporation's 8mm Graphite Rod will play a crucial role in the development of electric vehicles (EVs). By utilizing these rods in battery packs and cooling systems, automakers can enhance the overall performance and range of EVs. Furthermore, the exceptional heat resistance of graphite rods eliminates the need for additional cooling mechanisms, reducing the weight and complexity of EV components.Paragraph 3:Electronics manufacturing is an industry that requires materials with excellent electrical conductivity, thermal stability, and anti-corrosive properties. XYZ Corporation's 8mm Graphite Rod meets all these requirements and more, making it an ideal choice for the production of semiconductors, circuit boards, and various other electronic components. The introduction of this innovative product is poised to revolutionize electronics manufacturing, leading to more efficient and reliable devices.Paragraph 4:Furthermore, this remarkable graphite rod holds immense potential in the renewable energy sector, specifically in wind turbines and solar panels. The superior mechanical strength and durability of the XYZ Corporation's 8mm Graphite Rod ensure optimal performance and longevity in challenging environmental conditions. As the focus on renewable energy intensifies globally, this graphite rod will prove instrumental in enhancing the efficiency, enhancing productivity, and extending the lifespan of green energy infrastructure.Paragraph 5:XYZ Corporation has not only developed an exceptional product but also adopted eco-friendly manufacturing processes to support sustainability initiatives. The company's commitment to reducing carbon emissions and environmental impact sets a positive example for others in the industry. Additionally, its rigorous quality control measures, including thorough testing and compliance with international standards, affirm the reliability, consistency, and safety of the 8mm Graphite Rod.Conclusion:The introduction of XYZ Corporation's 8mm Graphite Rod marks a significant milestone in the industrial sector. With its exceptional strength, electrical conductivity, heat resistance and numerous other benefits, this innovative product is set to revolutionize industries such as aerospace, automotive, electronics, and renewable energy. As XYZ Corporation continues to push the boundaries of technological advancements, it reinforces its position as a global leader in graphite rod manufacturing, and industry stakeholders eagerly await the positive impact this new product will have on their respective fields.

Shop for Graphite Pencils - Extensive Range in Store and Online!

Graphite Disc: The Essential Element of All PencilsPencils are ubiquitous writing utensils that we rarely stop to consider. But have you ever stopped to think about what makes up the pencil you hold in your hand? One of the most fundamental components of a pencil is its graphite disc, which is responsible for giving the pencil its unique writing characteristics.In this blog, we will delve into all things graphite disc related, including its origins, properties, and uses. Whether you are a seasoned artist or simply someone who enjoys the feel of a good quality pencil, this article will provide you with valuable insights into the world of graphite discs.What is a Graphite Disc?A graphite disc is a small, thin piece of graphite that is cut to fit the shape of a pencil. It is typically mixed with clay and other materials before being molded into a rod that is surrounded by a wooden casing. This casing serves to protect the graphite rod and provide a comfortable grip for the user.Graphite itself is a form of carbon that is found naturally in rocks and minerals. It is a unique material with a wide range of physical and chemical properties, making it an ideal candidate for use in pencils.What Makes a Graphite Disc Unique?When it comes to writing, graphite pencils have a distinct advantage over other types of writing instruments. The reason for this is due to the unique properties of graphite itself.Graphite is a soft material that easily leaves a mark on paper, yet it is also strong enough to withstand normal writing pressure without breaking. Additionally, it can be graded into various levels of hardness depending on the intended use.For example, a soft lead pencil will require less pressure to produce a mark on paper and will create a darker line compared to a harder lead pencil that will require more pressure and produce lighter lines. This grading system, which ranges from 9H (the hardest) to 9B (the softest), gives users the flexibility to choose a pencil that best suits their individual needs.Uses of Graphite DiscsAlthough graphite discs are mainly used for making pencils, they also have a variety of other applications. Graphite is a highly conductive material which makes it ideal for use in electronic devices such as batteries and circuit boards. It is also used in lubricants and mold release agents due to its slippery surface properties.Graphite is also an important material in the aerospace industry, where it is used to make materials that can withstand high temperatures and pressures. Due to its refractory properties, it is also used in the production of crucibles and other refractory items that require high heat resistance.ConclusionIn conclusion, the graphite disc is an essential element of all pencils, and its unique properties are responsible for making pencils a popular writing tool worldwide. From artists to engineers, people use graphite pencils every day to express themselves and create works of art.Next time you pick up a pencil, take a moment to appreciate the humble graphite disc that makes it all possible. And if you're ever in need of pencils, shop at a store like Eckersley's extensive online and in-store range of pencils. Enjoy now and pay later using Afterpay or ZIP!

Revolutionizing the Graphite Industry: Unveiling the Power of Vibrated Graphite

Title: Groundbreaking Innovation in Graphite Materials Propels Renewable Energy TechnologiesIntroduction:In a major breakthrough for the renewable energy industry, researchers at an undisclosed company have developed Vibrated Graphite, a game-changing material that promises to revolutionize the efficiency and performance of numerous renewable energy technologies. Combining groundbreaking research and cutting-edge manufacturing techniques, the company stands at the forefront of developing advanced solutions for a sustainable future.Paragraph 1:Graphite has long been hailed as a key component in various renewable energy applications due to its excellent electrical conductivity, thermal stability, and corrosion resistance. However, the company's newly developed Vibrated Graphite takes these properties to unprecedented levels, marking a significant milestone in the industry. By combining their expertise in materials science and engineering, the company has been successful in fine-tuning the manufacturing process to deliver a product that surpasses conventional graphite in terms of performance and suitability for renewable energy technologies.Paragraph 2:One of the major applications where Vibrated Graphite is set to make a considerable impact is in lithium-ion batteries. The vast majority of electric vehicles (EVs) and grid-scale energy storage systems rely on these batteries, which are currently limited by the performance of the graphite anode. By incorporating Vibrated Graphite into battery anodes, the company aims to increase energy storage capacity, enhance charge-discharge rates, and prolong battery lifespan, ultimately driving the transition towards more sustainable transportation and grid systems.Paragraph 3:Moreover, Vibrated Graphite reveals exceptional potential in the field of solar energy. The material's unique properties allow for the efficient collection, transfer, and storage of solar-generated electricity. From solar panels and concentrated solar power systems to solar-powered devices, Vibrated Graphite has the ability to optimize energy conversion and improve overall system efficiency. This breakthrough holds immense promise in promoting the widespread adoption of renewable energy sources, fostering a greener and more sustainable world.Paragraph 4:Wind energy is another area where Vibrated Graphite could prove instrumental. Wind turbines, as vital components of wind energy generation, require lightweight and durable materials to withstand harsh environmental conditions while maximizing energy production. With its exceptional mechanical strength and thermal stability, Vibrated Graphite shows immense potential in the manufacturing of wind turbine blades, resulting in increased efficiency, reduced maintenance costs, and enhanced overall performance. This innovation paves the way for more reliable and cost-effective wind power solutions.Paragraph 5:In addition to its applications in specific renewable energy technologies, Vibrated Graphite can also benefit the broader energy industry. With the global emphasis shifting towards decarbonization and sustainability, energy infrastructure requires materials that can withstand higher temperatures and possess superior electrical and thermal conductivity. The company's Vibrated Graphite has the potential to replace conventional materials like copper and aluminum in various energy transmission and storage systems, significantly improving their efficiency and reducing environmental impact.Paragraph 6:The significance of Vibrated Graphite extends beyond the renewable energy sector. The material holds immense promise for advanced electronics, aerospace, and defense industries, where its exceptional properties can elevate the performance of electronic devices, aircraft components, and protect equipment. This versatility and potential for cross-industry applications further highlight the transformative impact of this innovative breakthrough.Conclusion:The development of Vibrated Graphite marks a pivotal moment in the evolution of renewable energy technologies. With its exceptional properties and wide-ranging applications, this revolutionary material has the potential to reshape the renewable energy landscape and propel us towards a cleaner, greener future. The company's commitment to sustainable innovation and dedication to pushing the boundaries of materials science have positioned them as a frontrunner in the renewable energy revolution.

Unlocking Potential: The Power of Customized Graphite Molds in Various Industries

Customized Graphite Mold: A Precise Solution for Diverse Industries(Graphic: Customized Graphite Mold)In today's rapidly advancing manufacturing sector, the demand for tailored solutions has become more pronounced than ever. Customization is the key to achieving high-quality production, meeting unique requirements, and ensuring cost-effectiveness. Understanding this need, one company has stepped forward to provide a groundbreaking solution - Customized Graphite Mold.Graphite molds have long been recognized as a reliable tool in various industries, including automotive, aerospace, electronics, and more. These molds are used primarily in casting and shaping products made from metals and alloys. However, with evolving customer demands and technology advancements, traditional graphite molds are no longer sufficient. This is where the innovative prowess of Customized Graphite Mold comes into play.Customized Graphite Mold, developed by an industry-leading company, is revolutionizing the way molds are manufactured and utilized. By harnessing cutting-edge techniques, the company ensures that each graphite mold is specifically tailored to meet the exact requirements and specifications of the customer.The unique selling point of Customized Graphite Mold lies in its ability to deliver precision and accuracy. With the aid of advanced computer-aided design (CAD) software, the company can create 3D models of the desired products, allowing for a meticulous and detailed customization process. This technology-driven approach eliminates the limitations of traditional mold design and opens up new possibilities for manufacturers.One of the key advantages of Customized Graphite Mold is its versatility. It can be used to create molds for a wide range of applications, including complex geometries, intricate designs, and intricate features. Whether it is automotive engine parts with intricate cooling passages or aerospace components requiring specific tolerances, Customized Graphite Mold can deliver the desired outcome with utmost precision.Moreover, the innovative design and manufacturing techniques employed by Customized Graphite Mold ensure exceptional heat resistance and thermal stability. This makes it an ideal solution for high-temperature casting processes, providing durability and longevity to the molds. Additionally, the use of high-quality graphite material ensures minimal wear and tear, further enhancing the mold's lifespan.Another noteworthy feature of Customized Graphite Mold is its excellent surface finish. The company utilizes advanced machining technologies to achieve smooth and polished surfaces, thereby minimizing post-production operations. This not only saves time and resources but also enhances the overall quality and aesthetics of the final product.Furthermore, the company behind Customized Graphite Mold is committed to sustainability and environmental responsibility. Graphite, being a naturally occurring mineral, is an eco-friendly material, and the company ensures that its manufacturing processes adhere to stringent environmental standards. This dedication to sustainability makes Customized Graphite Mold a preferred choice for conscious manufacturers who prioritize green practices.In conclusion, Customized Graphite Mold is revolutionizing the manufacturing industry by offering tailor-made solutions that meet the ever-evolving needs of diverse sectors. With its advanced design capabilities, precision engineering, versatility, and commitment to sustainability, Customized Graphite Mold is positioning itself as a leading provider of cutting-edge mold technology. As manufacturing continues to evolve, companies who embrace such innovative solutions can stay ahead of the curve and ensure exceptional quality products in an increasingly competitive market.

Durable Graphite Saggers for High-Temperature N2 Firing - Buy Refractory Kiln Furniture at Affordable Prices

If you work in the ceramics or metallurgy industries, you may have come across the term graphite sagger. A graphite sagger is a type of kiln furniture that is used to hold materials during firing. In particular, it is designed to withstand high temperatures without deforming or breaking down.Graphite saggers are becoming increasingly popular due to their excellent thermal stability and resistance to oxidation. They are capable of withstanding temperatures of up to 3000°C, making them one of the best options for high-temperature processes.One of the most prominent features of graphite saggers is their ability to withstand firing in a nitrogen gas atmosphere. Nitrogen firing is a technique used in industries such as ceramics, metalworking, and specialty glass production, where materials need to be fired in an inert atmosphere to prevent oxidation. Graphite saggers are ideal for this process because they do not react to the nitrogen gas, ensuring that the material inside the sagger remains pure.In addition to their high-temperature resistance and ability to withstand nitrogen firing, graphite saggers also have excellent thermal shock resistance. This means they can withstand rapid changes in temperature without cracking or breaking down. This feature makes them an excellent choice for industries that require fast heating and cooling rates.Graphite saggers also have a low coefficient of thermal expansion, which means they expand and contract less than other ceramics at high temperatures. This makes them less susceptible to thermal stress and cracking.When it comes to choosing graphite saggers, it’s important to consider the size, shape, and composition of the material being fired. Graphite saggers come in a range of sizes, including round, square, and rectangular shapes. The composition of the sagger can also affect its performance, with some manufacturers using a higher percentage of graphite to improve thermal stability and increase its lifespan.In conclusion, if you’re in the ceramics, metalworking, or specialty glass production industries, a graphite sagger could be an excellent choice for your high-temperature firing needs. With their exceptional thermal stability, resistance to oxidation, and ability to withstand rapid heat and cooling rates, graphite saggers are an excellent investment for any high-temperature process. So, if you’re in the market for graphite saggers, make sure you choose a reputable supplier that offers high-quality products that meet your specific needs.

High-Quality Graphite Boats on the Rise in China

China-based graphite boat manufacturer, XX Company, has recently introduced a new range of high-quality graphite boats to its product portfolio. The new boats are designed for use in high-temperature applications such as the manufacturing of semiconductor materials and solar silicon wafers.Graphite boats are a key component in various heat-treating applications, particularly in the semiconductor and solar industries. They are used to hold and transport small pieces of semiconducting or solar wafers through the high-temperature furnace. The high-quality graphite material used in these boats provides excellent thermal conductivity, chemical resistance, and thermal shock resistance, making it perfect for high-temperature applications.With over 10 years of experience in manufacturing high-quality graphite products, XX Company has established itself as one of the leading suppliers of graphite boats in China. The company has a strong presence in the domestic market and has also been exporting its products to various countries around the world, including South Korea, Japan, and the United States.The company has invested heavily in research and development to improve the quality of its graphite products. The new range of boats is a testament to the company's commitment to providing its customers with high-quality, reliable products. The boats are made using high-purity graphite, which ensures a uniform and consistent structure, resulting in superior thermal conductivity and chemical resistance.Additionally, the company uses advanced manufacturing techniques to produce boats with precise dimensions and tolerances, ensuring they fit perfectly into the high-temperature furnaces and can transport the delicate semiconductor and solar wafers without any damage.One of the key advantages of XX Company's graphite boats is their long service life. Typically, graphite boats have a life span of around 50-100 uses, depending on the specific application and operating conditions. However, XX Company's boats are designed to last up to 150 uses, which translates into significant cost savings for its customers.The company's dedication to quality and reliability has earned it a reputation as a trusted supplier of graphite boats in the industry. The company has a stringent quality control process in place to ensure that its products meet the highest standards. Each boat undergoes rigorous testing and inspection before being shipped to customers, guaranteeing that it performs as expected in the high-temperature furnace.In addition to its standard product range, XX Company also offers custom-made graphite boats to suit specific customer requirements. The company's engineering team works closely with customers to understand their unique needs and creates bespoke solutions that meet their exact specifications.With a comprehensive product range, excellent quality, and reliable performance, XX Company is well-positioned to be a major player in the global graphite boat market. The company's commitment to innovation and quality has enabled it to establish a strong foothold in the industry and will continue to drive its growth in the years to come.

Discover the Essential Functions and Applications of a Rotary Kiln

Title: Revolutionary Rotary Kiln Technology Poised to Transform the IndustryIntroduction:In a world constantly seeking more sustainable alternatives, the renowned engineering company {} is set to revolutionize the industry with their groundbreaking rotary kiln technology. Offering a comprehensive solution to address the challenges of traditional processes, their innovative rotary kiln design aims to significantly reduce carbon emissions, improve energy efficiency, and enhance the long-term sustainability of production across various sectors.Body:1. The Need for Innovations in Rotary Kiln Technology (150 words):The conventional rotary kiln has been widely used in industries like cement, minerals, and chemicals, among others, for decades. However, it inherently suffers from several shortcomings, including high energy consumption, significant greenhouse gas emissions, and limited operational flexibility. As the world increasingly prioritizes eco-friendliness and sustainability, there has been a growing demand for advanced technologies that can mitigate the environmental impact of manufacturing processes.2. Introducing the Revolutionary {} Rotary Kiln (150 words):{} has heeded this call for change by developing an exceptional rotary kiln technology that promises to reshape the industry. By incorporating cutting-edge engineering principles, this innovative design optimizes energy efficiency while drastically reducing carbon emissions. Transforming the conventional rotary kiln into an advanced and sustainable solution, the new design enables production plants to meet strict environmental regulations, achieve substantial cost savings, and enhance operational flexibility.3. Key Features and Benefits (200 words):The updated rotary kiln design integrates several game-changing features, elevating its performance and sustainability. A few significant highlights include:a. Enhanced Energy Efficiency: The {} rotary kiln utilizes advanced heat recovery systems and optimized insulation techniques, significantly improving thermal efficiency and reducing energy consumption. This leads to substantial cost savings and a more sustainable manufacturing process.b. Reduced Carbon Footprint: By effectively capturing and neutralizing harmful greenhouse gas emissions, the new rotary kiln technology helps industries make substantial progress towards achieving their carbon reduction goals. The design minimizes toxic pollutant discharge into the atmosphere, ensuring compliance with stringent environmental regulations.c. Operational Flexibility: {} rotary kiln technology offers remarkable flexibility, allowing for the processing of a wide range of materials, including cement, minerals, and even industrial waste. This versatility enables production plants to adapt quickly to changing market demands, minimizing downtime and maximizing operational efficiency.d. Enhanced Safety Features: The new rotary kiln design incorporates state-of-the-art safety measures, ensuring the well-being of workers while minimizing the risk of accidents or incidents during operation.4. Applications and Potential Impact (200 words):The profound impact of the revolutionary {} rotary kiln technology extends to a myriad of industries. Cement manufacturers can vastly reduce their carbon footprint and energy costs, while simultaneously increasing cement production capacity. Furthermore, the mineral processing industry can achieve greater efficiency and cost-effectiveness in extracting valuable minerals.Additionally, the steel industry can leverage this technology to improve energy efficiency and decrease carbon emissions in the production of iron ore pellets. Other potential applications include the treatment of hazardous waste and the production of alternative fuels from biomass and municipal solid waste, fostering a circular economy.5. Collaboration and Future Outlook (100 words):{} is actively seeking collaborative partnerships with industry leaders to further refine and implement their cutting-edge rotary kiln technology. By combining their technical expertise with the industry's demands, {} aims to continuously enhance their innovative solution and drive sustainability across various sectors globally.Conclusion:With the introduction of their revolutionary rotary kiln technology, {} has opened up a new era for the industry, providing a transformative approach to energy efficiency, reduced carbon emissions, and enhanced operational flexibility. As industries rapidly transition towards sustainability, this innovation stands poised to become the go-to solution, ensuring a greener and more efficient manufacturing landscape for generations to come.

Top Quality Graphite Crucibles for Aluminum Casting Available Now

Graphite Crucibles for Aluminium - The Crucial Commodity Driving the Global Metals IndustryThe global metals industry is witnessing a steady growth in demand for high-quality aluminium and its alloys, primarily driven by the rising requirements in the transportation and aerospace sectors. To meet this demand, aluminium manufacturers are required to use advanced technologies and quality materials. One such critical material used in the production of aluminium is graphite crucibles.Graphite crucibles are one of the most essential parts of the aluminium production process, and their correct selection plays a crucial role in maintaining the quality standards of the end product. In recent years, there has been a growing demand for graphite crucibles that are durable, heat-resistant, and can withstand the high temperatures required in the aluminium smelting process.A leading manufacturer of graphite crucibles for aluminium has been meeting this growing demand in the global market. This company, which has operations across Asia, Europe and North America, is known for its extensive range of quality graphite crucibles that cater to various stages of the aluminium production process. They offer an extensive range of high-performance graphite crucibles that are suitable for various furnace types, and can be customised according to specific customer requirements.The company has also been leveraging on advanced manufacturing technologies such as isostatic pressing, CNC machining, and computerized modelling to ensure consistent quality in their crucibles. They employ a rigorous quality control process at every stage of the production process to ensure that their products meet or exceed customer expectations.Moreover, this company has continued to invest in research and development to improve their product offerings and stay ahead of competitors. They have also been working closely with customers to develop customised solutions tailored to their unique manufacturing requirements.The company's graphite crucibles are highly sought after in the global market, with a considerable market share in key regions such as Asia, Europe, and North America. They serve a broad range of industries, including aerospace, automotive, construction, energy, and packaging.In recent years, the growth in demand for aluminium and its alloys has been driven by the increasing need for lightweight materials that offer high strength and durability. This trend has been particularly evident in the transportation and aerospace sectors, where manufacturers are required to reduce weight without compromising on safety or performance. Graphite crucibles have played a vital role in enabling manufacturers to meet these requirements and produce high quality aluminium and its alloys.Looking forward, the demand for graphite crucibles for aluminium is anticipated to continue growing, driven by the increasing adoption of lightweight materials in various industries. This trend is expected to result in new opportunities for the global graphite crucibles market, with manufacturers looking to expand their product offerings to cater to different stages of the aluminium production process.In conclusion, the graphite crucibles for aluminium market is a crucial commodity driving the global metals industry. The quality of graphite crucibles used in the aluminium production process is vital in ensuring consistent performance and quality of the end products. The leading manufacturer of graphite crucibles for aluminium has been meeting this demand by offering an extensive range of high-performance products, leveraging on advanced technologies and stringent quality control processes. With the increasing demand for lightweight materials, the graphite crucibles market is expected to grow, presenting new opportunities for manufacturers to cater to evolving customer requirements.