Durable High-Density Graphite Rod: Uses and Benefits

By:Admin

Graphite is known for its versatility and strength, making it an essential material for numerous industrial applications. The use of high-density graphite rods has gained immense popularity due to their exceptional properties and extensive benefits. [Company Name], a leading manufacturer of high-quality graphite products, is proud to introduce its high-density graphite rods that cater to the growing demand for reliable and durable materials in various industries.

The high-density graphite rods offered by [Company Name] are engineered to deliver superior performance in demanding environments. These rods are manufactured using premium quality graphite materials that are carefully selected to ensure exceptional strength, durability, and resistance to extreme temperatures and corrosion. With a high density and excellent thermal conductivity, these graphite rods are ideal for applications that require high thermal stability and electrical conductivity.

One of the key advantages of high-density graphite rods is their versatility, making them suitable for a wide range of industrial applications. From the aerospace and automotive industries to the steel and semiconductor sectors, high-density graphite rods play a crucial role in enhancing the efficiency and performance of various equipment and processes. Their ability to withstand high temperatures and harsh operating conditions makes them an ideal choice for furnace components, heating elements, crucibles, and other critical applications.

In addition to their remarkable strength and thermal properties, high-density graphite rods also offer significant cost savings for industrial operations. Their long service life and minimal maintenance requirements contribute to reducing downtime and operational costs, making them a cost-effective solution for companies looking to improve productivity and efficiency. Furthermore, the lightweight nature of high-density graphite rods helps minimize the overall weight of equipment and machinery, leading to additional energy savings and reduced environmental impact.

[Company Name] takes pride in its state-of-the-art manufacturing facilities and cutting-edge production techniques that enable the company to produce high-density graphite rods of the highest quality. The company's team of skilled engineers and technicians work tirelessly to ensure that every graphite rod meets the strictest quality standards and exceeds customer expectations. With a commitment to innovation and continuous improvement, [Company Name] is dedicated to staying at the forefront of graphite technology and providing its customers with the most advanced and reliable graphite products.

As a testament to its unwavering dedication to excellence, [Company Name] has established a reputation for delivering exceptional customer service and technical support. The company's team of experts is readily available to provide valuable assistance and guidance to customers, ensuring that they receive the most suitable graphite solutions for their specific requirements. Whether it's assisting with product selection, providing technical advice, or offering custom manufacturing capabilities, [Company Name] is committed to supporting its customers every step of the way.

With the growing demand for high-density graphite rods across various industries, [Company Name] is well-positioned to meet the needs of its customers and deliver unparalleled value. The company's unwavering commitment to quality, reliability, and customer satisfaction sets it apart as a trusted leader in the graphite industry. By offering innovative graphite solutions that optimize performance and efficiency, [Company Name] continues to be the preferred choice for companies seeking top-quality graphite products.

In conclusion, high-density graphite rods offered by [Company Name] provide an array of benefits that make them indispensable for a wide range of industrial applications. With their exceptional strength, thermal conductivity, and cost-saving advantages, these graphite rods offer a reliable and cost-effective solution for companies looking to enhance their operations. Backed by [Company Name]'s dedication to quality and customer support, these high-density graphite rods have solidified their position as a valuable asset in the industrial sector.

Company News & Blog

Discover the Benefits and Applications of Graphite Sintering Moulds

Title: Groundbreaking Graphite Sintering Mould Innovates Industrial ManufacturingIntroduction:In a significant stride towards revolutionizing industrial manufacturing processes, a cutting-edge technology has emerged - the Graphite Sintering Mould, created by an innovative company. This groundbreaking advancement holds the potential to transform various industries by providing more efficient and cost-effective solutions for producing high-quality goods. By combining the advantages of graphite as a material with ingenious mold designs, this pioneering technology is set to redefine the future of manufacturing.(Graphite Sintering Mould) – A Game-Changing Technology:(Graphite Sintering Mould) is an advanced manufacturing tool that utilizes graphite as the primary material in its mold construction. Graphite, renowned for its exceptional properties such as high thermal conductivity, low thermal expansion, and resistance to chemical corrosion, proves to be an ideal material for creating molds. The unique combination of these characteristics sets the stage for accelerating the industrial manufacturing process.(Graphite Sintering Mould) excels in a wide range of applications, including automotive, aerospace, electronics, and more. Traditionally, manufacturing processes involve the use of metal molds, which are expensive, time-consuming to produce, and have limited lifespans. However, Graphite Sintering Mould overcomes these limitations by offering unparalleled advantages.Elevating Manufacturing Efficiency:An essential aspect of (Graphite Sintering Mould) is its distinctive mold design, tailored to specific production requirements. This technology enables the production of molds with intricate shapes, precise dimensions, and excellent heat transfer capabilities. Compared to traditional molds, the use of Graphite Sintering Mould significantly reduces the cycle time, resulting in increased production efficiency and cost savings.(Graphite Sintering Mould) molds possess superior thermal conductivity, ensuring uniform heat distribution during the manufacturing process. This feature eliminates hotspots and minimizes thermal stress, thereby enhancing the overall quality and consistency of the finished products. Manufacturers can now achieve higher precision, reduced waste, and greater control over the manufacturing process, resulting in enhanced customer satisfaction.Environmental-Friendly and Cost-Effective Solution:(Graphite Sintering Mould) also offers environmental advantages by minimizing energy consumption and material waste. The high thermal conductivity of graphite enables faster heating and cooling cycles, reducing power requirements and improving energy efficiency. Additionally, the durability and longevity of (Graphite Sintering Mould) molds enable companies to produce a significantly larger number of items, thus reducing the need for frequent mold replacements.Moreover, the reduced production time and enhanced efficiency provided by (Graphite Sintering Mould) molds translate into significant cost savings for manufacturers. Companies can allocate their resources more strategically, invest in research and development, and explore new market opportunities.Emerging as a Pioneer in Industrial Manufacturing:The company behind the development of (Graphite Sintering Mould) stands at the forefront of innovation in the industrial manufacturing sector. Through extensive research and development, the company has successfully harnessed the unique properties of graphite and perfected the technology to produce reliable, high-performance molds.The exceptional quality of molds generated using (Graphite Sintering Mould) has garnered attention from major industries worldwide. Their commitment to sustainable practices alongside their relentless pursuit of excellence positions the company as a leading pioneer in the manufacturing field.Looking Forward:The introduction of (Graphite Sintering Mould) marks a significant milestone in the evolution of industrial manufacturing. With its ability to enhance production efficiency, reduce costs, and deliver superior quality products, this technology holds vast potential for various sectors. Manufacturers across the globe are eagerly adopting this groundbreaking method, propelling the industry toward a more sustainable and efficient future.As researchers continue to refine and expand the capabilities of (Graphite Sintering Mould), we can anticipate further advancements that will revolutionize the way products are manufactured. With improved mold designs, expanded applications, and increased efficiency, the possibilities for innovation with this game-changing technology are limitless.

High-Quality Graphite Boat for Alloys Manufactured in China

China Graphite Boat for AlloysGraphite is a widely used material in various industries, and its use in the production of alloys is no exception. The demand for high-quality graphite boats for the production of alloys has been increasing, and China has been at the forefront of meeting this demand. One company that has been making significant contributions in this field is {company's name}.{Company's name} is a leading manufacturer and supplier of graphite products, including graphite boats for the production of alloys. The company has been serving the needs of customers in the alloy industry with its high-quality products and excellent service. With a strong focus on quality and innovation, {company's name} has been able to establish itself as a trusted supplier in the industry.The graphite boats produced by {company's name} are known for their high purity and excellent thermal stability, making them ideal for use in the production of alloys. The company uses advanced manufacturing processes and high-quality raw materials to ensure that its graphite boats meet the stringent requirements of the alloy industry. With a commitment to quality and reliability, {company's name} has become a preferred supplier for many alloy manufacturers in China and beyond.In addition to its high-quality products, {company's name} is also known for its excellent customer service. The company works closely with its customers to understand their specific needs and provide them with tailored solutions. Whether it's a standard graphite boat or a custom-designed product, {company's name} is able to deliver according to the customer's requirements.The company's dedication to innovation and continuous improvement has also led to the development of new and improved graphite products for the alloy industry. {Company's name} is constantly investing in research and development to stay abreast of the latest technological advancements and market trends. This ensures that the company is able to offer its customers the most advanced and reliable graphite products available.Furthermore, {company's name} places a strong emphasis on environmental sustainability. The company adheres to strict environmental standards in its manufacturing processes, ensuring that its products are not only of the highest quality but also environmentally friendly. This commitment to sustainability has resonated with many customers, further solidifying {company's name} as a trusted and responsible supplier in the industry.Looking ahead, {company's name} is poised to continue its growth and expansion in the graphite boat market for alloys. The company is constantly exploring new opportunities and markets, while also strengthening its existing relationships with customers. With a strong foundation built on quality, innovation, and customer service, {company's name} is well-positioned to meet the evolving needs of the alloy industry and remain a leader in the supply of graphite boats.In conclusion, {company's name} has established itself as a leading manufacturer and supplier of graphite boats for the production of alloys. The company's commitment to quality, innovation, and customer service has set it apart in the industry, making it a trusted partner for alloy manufacturers in China and beyond. With a focus on sustainability and a drive for continuous improvement, {company's name} is well-equipped to meet the ever-increasing demand for high-quality graphite products in the alloy industry.

Affordable Graphite Vane Plates for Vacuum Pumps - High-Quality Manufacturers & Suppliers in China

Graphite Plate Price: Cost-Effective Solutions for High-Performance Vacuum PumpsWhen it comes to vacuum pumps, every component plays a crucial role in ensuring optimal performance and longevity. One such component is the graphite vane plate, which is used in rotary vane vacuum pumps to create a seal and generate suction.If you're in the market for high-quality graphite vane plates at a reasonable price, look no further than China - a leading manufacturer of these components. In this blog, we'll explore the benefits of using graphite vane plates and how to find the best prices.Why Choose Graphite Vane Plates for Vacuum Pumps?Graphite is an excellent material for vacuum pump vane plates due to its unique properties. Unlike metals, graphite is self-lubricating, meaning it can withstand high temperatures and operate without additional oil or lubricants. This makes it ideal for use in vacuum pumps that require high-speed, continuous operation.Graphite vane plates are also highly resistant to wear and tear, chemical corrosion, and oxidation. They offer excellent dimensional stability and can withstand extreme pressure differentials, making them suitable for use in harsh industrial environments.Another notable advantage of using graphite vane plates is their low friction and superior vibration damping properties. This helps reduce noise and vibration levels, which is crucial for applications that require low noise emissions like medical equipment, laboratories, and semiconductor manufacturing.Finding the Best Graphite Plate PriceIf you're looking to source high-quality graphite vane plates at a competitive price, consider partnering with a reputable manufacturer in China. China has emerged as a global leader in the production of graphite components, offering a wide range of products with different specifications, sizes, and shapes to suit various applications.When selecting a supplier, it's essential to consider several factors, such as quality, delivery time, packaging, and customer service. Look for a company that uses advanced production facilities and strict quality control measures to ensure consistent quality.Also, consider the supplier's pricing policy, payment methods, and shipping options. Some suppliers may offer discounts for bulk orders or provide free samples for testing purposes. It's also essential to ensure that the supplier can provide timely and secure shipping to your destination.ConclusionIn summary, graphite vane plates are an essential component of rotary vane vacuum pumps, offering superior performance, durability, and reliability in harsh industrial environments. Investing in high-quality graphite vane plates can help you reduce maintenance costs, increase productivity, and improve operational efficiency.If you're looking for the best graphite plate price, turn to China - a reliable and cost-effective source of high-quality graphite components. Selecting the right supplier can help you achieve your production goals and stay competitive in the global market.

High-Quality Carbon Graphite Block: What You Need to Know

Carbon Graphite Block, a leading company in the field of carbon graphite products, has announced the release of their latest innovation in graphite blocks. These blocks are the result of years of research and development, and are set to revolutionize the industry with their advanced properties and exceptional performance.With a long history of providing high-quality carbon graphite products to a wide range of industries, Carbon Graphite Block has established itself as a trusted and reliable partner for companies seeking innovative solutions for their graphite needs. Their team of experts is dedicated to pushing the boundaries of graphite technology, and their latest release is a testament to their commitment to excellence.The new graphite blocks are designed to offer superior performance in a variety of applications, including aerospace, automotive, energy, and industrial manufacturing. They are manufactured using the highest quality materials and cutting-edge production techniques, ensuring unmatched consistency and reliability. This level of quality is essential for industries that rely on graphite products for critical applications, and Carbon Graphite Block has positioned themselves as a leader in meeting these demands.One of the key features of the new graphite blocks is their exceptional thermal conductivity. This property makes them ideal for applications where heat dissipation is crucial, such as in high-performance electronic devices and thermal management systems. The blocks also exhibit high strength and durability, making them a versatile choice for a wide range of industrial applications.In addition to their advanced technical properties, the graphite blocks are also designed with ease of use in mind. Their uniform structure and precise dimensions ensure that they can be integrated seamlessly into existing systems, minimizing downtime and production disruption. This level of convenience is a testament to Carbon Graphite Block's dedication to providing practical solutions for their customers.Carbon Graphite Block's commitment to quality is further reflected in their stringent quality control measures and rigorous testing protocols. Each batch of graphite blocks undergoes thorough inspection to ensure that they meet the company's exacting standards for performance and reliability. This attention to detail is crucial for industries where even the slightest deviation in material properties can have serious consequences.With the release of their latest graphite blocks, Carbon Graphite Block has once again demonstrated their leadership in the field of carbon graphite products. Their commitment to innovation and excellence has solidified their position as a trusted partner for companies seeking reliable solutions for their graphite needs. As industries continue to demand higher performance and reliability from their materials, Carbon Graphite Block stands ready to meet these challenges with their advanced graphite products.In conclusion, Carbon Graphite Block's latest innovation in graphite blocks represents a significant advancement in the field of carbon graphite products. With their exceptional thermal conductivity, high strength, and durability, these blocks are set to revolutionize a wide range of industries. Coupled with the company's dedication to quality and reliability, Carbon Graphite Block has once again proven themselves as a leader in the field. As companies continue to seek innovative solutions for their graphite needs, Carbon Graphite Block stands ready to meet these demands with their cutting-edge products and expertise.

High-Quality Carbon Graphite Crucible for Industrial Applications

Carbon Graphite Crucible, a vital component in the metallurgy and foundry industries, is a high-quality, durable and heat-resistant solution for melting and casting a wide range of materials. This essential tool is now available through the innovative and customer-focused company, [Company Name].[Company Name] is a leading supplier of carbon graphite products and materials for various industries. With a strong focus on quality, reliability and customer satisfaction, the company has established a reputation for providing exceptional products and services to its clients.The Carbon Graphite Crucible offered by [Company Name] is designed to withstand extreme temperatures and harsh conditions, making it ideal for use in the melting and casting of metals such as gold, silver, aluminum, copper, and more. The crucible’s unique properties, including high thermal conductivity and resistance to chemical erosion, make it an indispensable tool for manufacturers and foundries.In addition to its exceptional durability and thermal properties, the Carbon Graphite Crucible from [Company Name] is also known for its consistent performance and high level of purity. This ensures that the materials being melted and cast remain free from contamination, leading to high-quality end products for manufacturers and artisans.Furthermore, [Company Name] offers a range of carbon graphite crucibles in various shapes, sizes, and configurations to meet the specific needs of its customers. Whether it’s for small-scale artisanal use or large-scale industrial applications, the company provides crucibles that are tailored to the unique requirements of each client.The carbon graphite crucibles provided by [Company Name] are manufactured using the latest technologies and industry best practices. This ensures that the products meet the highest standards of quality and performance, giving customers the confidence and assurance that they are investing in a reliable and long-lasting solution.With a commitment to customer satisfaction, [Company Name] also offers personalized support and assistance to help clients choose the right carbon graphite crucible for their specific needs. The company’s team of experts is dedicated to understanding the unique requirements of each customer and providing tailored solutions that meet and exceed expectations.In addition to its extensive range of carbon graphite crucibles, [Company Name] also offers a wide selection of carbon graphite products and materials for various industrial applications. From crucible furnaces and heaters to carbon graphite rods and plates, the company serves as a one-stop shop for all carbon graphite needs.As an industry leader, [Company Name] is dedicated to continuous innovation and improvement. The company invests in research and development to bring new and advanced carbon graphite products to the market, ensuring that its customers have access to the latest and most cutting-edge solutions.With a strong focus on sustainability and environmental responsibility, [Company Name] also places a high priority on ethical and eco-friendly manufacturing practices. The company is committed to reducing its environmental footprint and promoting the use of sustainable materials in its products.In conclusion, the availability of Carbon Graphite Crucible through [Company Name] is a significant development for the metallurgy and foundry industries. With its exceptional quality, durability, and performance, the crucible is set to become an essential tool for manufacturers and artisans working with a wide range of materials. Coupled with [Company Name]’s commitment to excellence and customer satisfaction, this offering is sure to have a positive impact on the industry as a whole.

Experts Share Tips on Making Graphite Molds for Precision Manufacturing

Vancouver, Canada - A leading graphite mold manufacturer has announced a new addition to its product line that promises to further solidify its position as a top player in the industry. The company, which specializes in producing high-quality graphite molds, has unveiled its latest product offerings that are geared towards providing customers with even more options for their applications.Graphite molds are an essential part of the manufacturing process for a wide range of industries, including the automotive, aerospace, and medical industries. They are used to create intricate and precise shapes, as well as the replication of complex designs. The company's graphite molds have long been known for their durability, strength, and precision, making them a favorite among industry professionals and manufacturers.The addition of these new products is set to broaden the company's reach and enhance its offerings to customers. The company has always been at the forefront of innovation in the industry, constantly adapting to new technologies and trends to stay ahead of the competition. The new graphite molds are no different, with a focus on precision, accuracy, and quality."Our new products are designed with our customers in mind," said the company spokesperson. "We understand that each client has unique needs, and our goal is to provide them with the best possible solutions to meet their requirements. We are confident that our new graphite molds will do just that."The new graphite molds come in a variety of shapes and sizes, making them suitable for different applications. The company has ensured that every mold meets the strictest quality standards to ensure maximum efficiency and effectiveness during the manufacturing process.Besides the quality and precision of the molds, the company has always placed great emphasis on customer service. In a highly competitive industry, customer satisfaction is crucial, and the company is well aware of that. The company spokesperson added that "our customers are at the heart of everything we do. We strive to exceed their expectations by providing them with the best products and services possible."The company's commitment to excellence has earned them a reputation as a dependable and trustworthy partner in the industry. They have worked with some of the biggest names in the business and have consistently delivered quality products and services that meet the client's needs."We are proud of our heritage and our contribution to the industry," said the spokesperson. "Our goal is to continue to build on that legacy and remain at the forefront of innovation in the graphite mold industry."With the unveiling of these new products, the company looks set to continue to dominate the industry and cement its position as a top manufacturer of graphite molds. The company's growth is a testament to its commitment to quality, innovation, and customer service, values that have earned it a loyal customer base and a reputation as a leading player in the industry. For customers looking for a reliable and high-quality graphite mold supplier, this company is worth considering. With its impressive track record, a focus on product innovation, and unmatched customer service, they are a dependable partner for manufacturing businesses of all sizes.

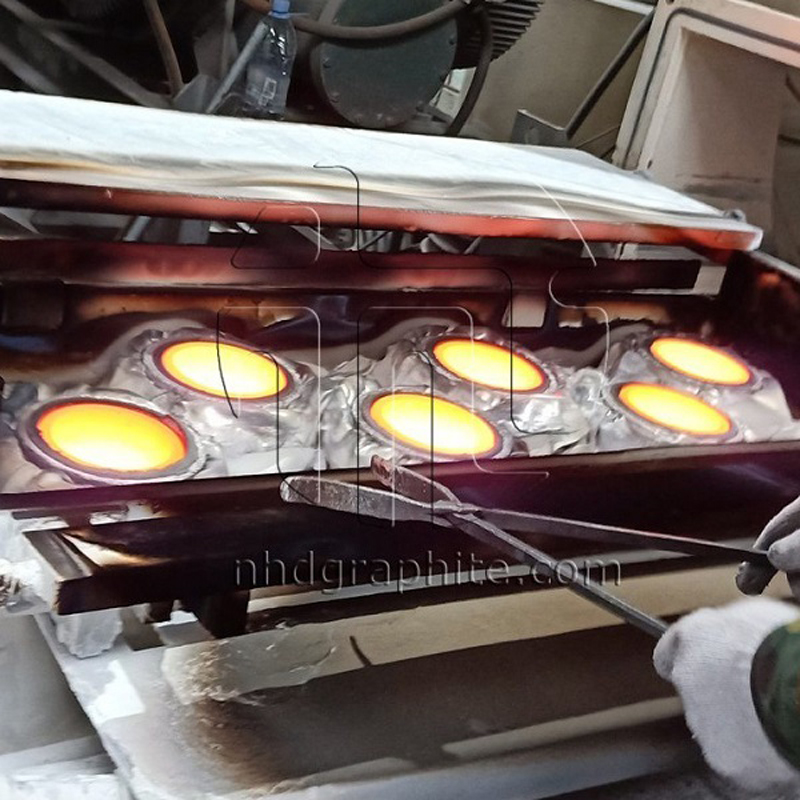

Durable Container for Hard Alloy: Innovative Solution for Storing Graphite Materials

Graphite Container for Hard Alloy Revolutionizes the Manufacturing Industry(Graphite Container for Hard Alloy) – In a groundbreaking development, a new innovative product, the Graphite Container for Hard Alloy, has been introduced by an industry-leading company. This game-changing technology is set to revolutionize the manufacturing industry by enhancing the production process of hard alloy materials.Hard alloys, also known as cemented carbides, are widely used in various industries due to their exceptional hardness, wear resistance, and strength. They are particularly prevalent in the automotive, aerospace, and tool manufacturing sectors. However, the conventional manufacturing process for hard alloys involves sintering, which involves compacting powdered metals at high temperatures and pressures. This process often leads to various challenges, such as deformation, cracks, and high scrap rates.The Graphite Container for Hard Alloy, developed by the pioneering company, aims to overcome these obstacles by providing a more efficient and cost-effective sintering solution. This advanced technology utilizes graphite, a material known for its high thermal conductivity and strength, as a container for the sintering process.By employing the Graphite Container for Hard Alloy, manufacturers can achieve greater control over the heat transfer during sintering. The unique properties of graphite allow for even distribution of heat, eliminating the risk of deformation and cracks in the hard alloy materials. This groundbreaking technology ensures consistent sintering quality, reducing scrap rates significantly.Moreover, the use of the Graphite Container for Hard Alloy offers several additional advantages. Firstly, the thermal conductivity of graphite allows for faster heat transfer, thereby reducing overall sintering time. This efficiency improvement translates into increased productivity and reduced production costs for manufacturers.Secondly, the graphite container boasts high chemical resistance, preventing any reaction between the container and the hard alloy material during the sintering process. This compatibility ensures the purity and integrity of the final product, enhancing its quality and performance.The Graphite Container for Hard Alloy is also highly durable and long-lasting. Its robust design enables it to withstand multiple sintering cycles without degradation or performance loss. This longevity contributes to the cost-effectiveness of the technology by reducing the need for frequent container replacements.In addition to these functional benefits, the implementation of the Graphite Container for Hard Alloy aligns with the growing focus on sustainability and eco-friendly manufacturing practices. This advanced technology reduces energy consumption and CO2 emissions since the shorter sintering time leads to lower energy requirements. Furthermore, the reduction in scrap rates minimizes material waste, contributing to a greener manufacturing process.The company behind this groundbreaking innovation, known for its commitment to research and development, has an established track record of delivering cutting-edge solutions to the manufacturing industry. With years of experience and expertise in the field of hard alloy production, they have successfully harnessed the potential of graphite to develop the Graphite Container for Hard Alloy.As this new technology gains traction in the manufacturing industry, it has the potential to revolutionize the way hard alloys are produced. The enhanced control over the sintering process, improved quality of the final product, increased productivity, and reduced environmental impact make the Graphite Container for Hard Alloy a game-changer in the industry.Manufacturers across various sectors will now have access to an innovative solution that addresses the challenges associated with traditional sintering methods. The introduction of this technology paves the way for more efficient, cost-effective, and sustainable production of hard alloy materials.In conclusion, the Graphite Container for Hard Alloy, developed by an industry-leading company, offers a revolutionary solution to the manufacturing industry. By harnessing the unique properties of graphite, this innovative technology enhances the sintering process, ensuring quality, efficiency, and sustainability. As manufacturers adopt this game-changing solution, they can look forward to improved production processes and enhanced hard alloy materials.

Shop Stylish and Affordable Roller Shades in Graphite - Enjoy Free Shipping | Window Treatments Department

Shades, Window Treatments, Home Decor, Light Control, Energy Efficiency, Privacy, Convenience, Style and DurabilityAt the mention of window treatments, the first thing that comes to mind is curtains. But, did you know that roller shades are just as effective in enhancing your home decor and serving a host of functional purposes? In this blog, we'll delve deeper into the world of roller shades, and highlight the benefits of choosing Graphite Roller Shades for your home. Firstly, let's talk about why roller shades are an excellent choice for your window treatments. Roller shades are known for their simplicity and functionality. They are designed to roll up and down smoothly, making them easy to operate. Unlike curtains, they take up less space, which is an advantage if you have limited space in your room. Moreover, they offer effective light control, energy efficiency, privacy, and convenience. When it comes to selecting roller shades, there are several options available in the market. However, not all roller shades are created equal. If you're looking for a roller shade that offers style and durability, Graphite Roller Shades from (need to remove brand name) are worth considering. Graphite Roller Shades are a popular choice for homeowners and interior designers alike, thanks to their elegant and sophisticated look. They come in a soft and soothing grey color that adds depth and dimension to any room. The graphite hue is versatile and complements a wide range of color schemes, making it easy to incorporate into your home's decor. Beyond style, Graphite Roller Shades are durable and built to last. They are made of high-quality materials that can withstand wear and tear, ensuring that they look great and function optimally for years to come. The Home Depot provides free shipping for Graphite Roller Shades or Buy Online Pick Up in Store today in the Window Treatments Department.Graphite Roller Shades are also efficient in controlling light and protecting your privacy. The shade's fabric is designed to filter out the sun's harsh rays, reducing glare and preventing fading of your furnishings. Additionally, they come in different opacity levels, allowing you to choose the level of privacy you want without impeding the natural lighting of your room. Another benefit of Graphite Roller Shades is energy efficiency. They help to regulate the temperature of your room by blocking out the sun's heat during summer and insulating your home, keeping it warm during winter. This results in lowered energy bills and a more comfortable living environment. In conclusion, roller shades are a sophisticated and practical alternative to traditional curtains. Graphite Roller Shades, in particular, offer style, durability, light control, energy efficiency, privacy, and convenience. They are a versatile option for any room in the house and are an excellent addition to your home decor. So, why not elevate your home's style and functionality by choosing Graphite Roller Shades today?

High quality graphite electrode plate latest news and updates

The demand for graphite electrode plates has been on the rise in various industries, including steel production, electronics, and automotive. These plates are essential for applications that require high levels of heat and electricity, making them a vital component in the manufacturing process.One company that has been at the forefront of producing high-quality graphite electrode plates is {Company Name}. With a strong focus on research and development, {Company Name} has been able to innovate and produce graphite electrode plates that meet the stringent requirements of modern industries.{Company Name} was founded in [year] and has since established itself as a leading manufacturer of graphite electrode plates. The company's state-of-the-art production facilities are equipped with the latest technology and machinery, allowing them to produce high-quality products with precision and accuracy.Furthermore, {Company Name} prides itself on its commitment to sustainability and environmental responsibility. The company has implemented stringent measures to minimize its carbon footprint and reduce waste in its manufacturing processes. This dedication to sustainability has not only helped {Company Name} reduce its impact on the environment but has also positioned them as a preferred supplier for eco-conscious industries.The success of {Company Name} can also be attributed to its strong emphasis on quality control. Every graphite electrode plate that leaves the company's production facility undergoes rigorous testing and inspection to ensure that it meets the highest standards of quality and performance. This commitment to quality has earned {Company Name} a stellar reputation in the industry, making them a trusted partner for numerous businesses worldwide.In addition to its dedication to quality, {Company Name} is known for its exceptional customer service. The company has a team of experienced professionals who work closely with clients to understand their specific requirements and provide tailored solutions. This customer-centric approach has allowed {Company Name} to build long-lasting relationships with its clients and establish itself as a reliable and trusted partner.Looking ahead, {Company Name} is poised to capitalize on the growing demand for graphite electrode plates. With the increasing use of electric vehicles, the expansion of the steel industry, and the ongoing advancements in electronics, the demand for graphite electrode plates is expected to continue to grow. {Company Name} is well-positioned to meet this demand and further solidify its position as a leading manufacturer in the industry.The company is also committed to ongoing research and development to further improve its products and develop new solutions to meet the evolving needs of its customers. By staying at the forefront of innovation, {Company Name} is well-equipped to continue meeting the diverse requirements of industries that rely on graphite electrode plates.In conclusion, {Company Name} is a leading manufacturer of graphite electrode plates, known for its commitment to quality, sustainability, and exceptional customer service. With a strong emphasis on research and development, the company is well-positioned to meet the growing demand for graphite electrode plates and continue to be a trusted partner for industries worldwide.

Discover the Uses and Benefits of High Purity Graphite

High Purity Graphite: The Essential Material for Emerging TechnologiesHigh purity graphite is a vital material for a wide range of emerging technologies, and one company at the forefront of its production is {Company Name}. With a commitment to sustainability and innovation, {Company Name} is playing a crucial role in meeting the growing global demand for high purity graphite.High purity graphite is an essential component in many cutting-edge technologies, including lithium-ion batteries, fuel cells, solar panels, and nuclear reactors. As these technologies continue to advance and become more widespread, the demand for high purity graphite is expected to skyrocket in the coming years. This presents a significant opportunity for companies like {Company Name} that are able to produce high quality graphite at scale.Founded in {Year}, {Company Name} is a leading producer of high purity graphite with a strong focus on sustainability and environmental responsibility. The company prides itself on its commitment to minimizing its environmental impact through the use of innovative production processes and renewable energy sources. With a vertically integrated business model that encompasses mining, processing, and distribution, {Company Name} is able to control the entire production process and ensure the highest quality standards are met.One of {Company Name}'s key strengths is its extensive experience and expertise in the field of graphite production. The company has invested heavily in research and development to develop cutting-edge technologies for refining graphite to the highest purity levels. By continuously improving its production processes, {Company Name} has been able to achieve exceptional levels of purity in its graphite products, making them highly sought after in the market.In addition to its commitment to sustainability and innovation, {Company Name} also places a strong emphasis on corporate social responsibility. The company is dedicated to supporting the communities in which it operates, and it has implemented various social and educational programs to benefit local residents. By fostering positive relationships with its stakeholders and prioritizing the well-being of its employees and local communities, {Company Name} is setting a positive example for the industry as a whole.As the demand for high purity graphite continues to rise, {Company Name} is well positioned to capitalize on this growing market opportunity. With its proven track record of producing high quality graphite in an environmentally responsible manner, the company is poised to become a key player in the global graphite industry. By leveraging its expertise, commitment to sustainability, and dedication to corporate social responsibility, {Company Name} is primed for continued success and growth in the years to come.In conclusion, high purity graphite is a crucial material for a wide range of emerging technologies, and {Company Name} is a leading producer in the industry. With its focus on sustainability, innovation, and corporate social responsibility, the company is well positioned to meet the growing global demand for high purity graphite. As the market for high purity graphite continues to expand, {Company Name} is set to play a key role in driving the industry forward and shaping the future of emerging technologies.