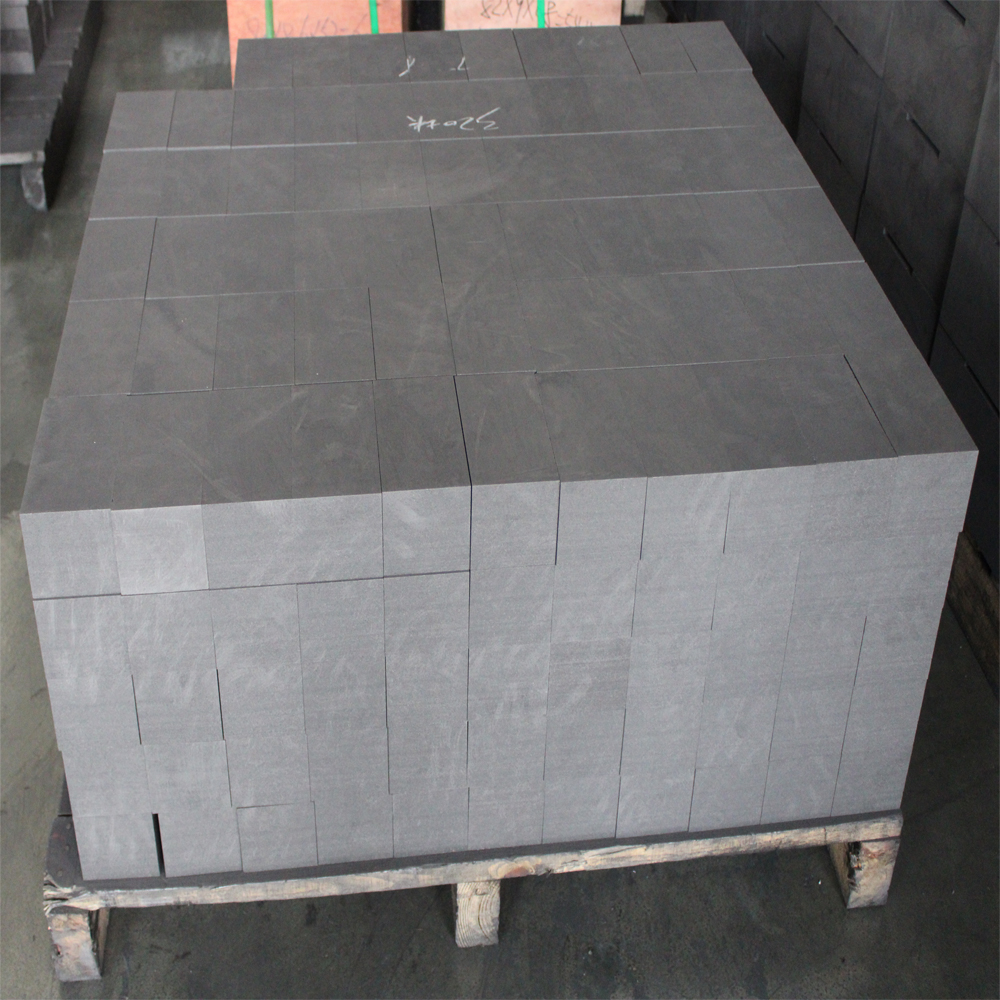

High-Quality Carbon Graphite Casting Moulds for Effective Casting Operations

By:Admin

Innovations in manufacturing technology have always been a driving force behind the advancement of various industries. One such innovative product that has recently gained attention is the Carbon Graphite Casting Mould, which is revolutionizing the way in which complex parts and components are produced.

The Carbon Graphite Casting Mould, developed by a leading company in the manufacturing industry, is designed to address the challenges of producing high-quality, intricate components for a wide range of applications. The mould is made from high-quality carbon graphite material, which is known for its exceptional strength, durability, and thermal resistance. This makes it an ideal choice for casting moulds, as it can withstand the extreme temperatures and pressures involved in the casting process.

The use of carbon graphite in the manufacturing of casting moulds offers a number of advantages over traditional materials such as steel and aluminum. Carbon graphite is significantly lighter than steel, which makes it easier to handle and transport. Additionally, it has a low coefficient of thermal expansion, which means that it remains dimensionally stable at high temperatures, resulting in minimal distortion or warping during the casting process.

Furthermore, the exceptional thermal conductivity of carbon graphite allows for faster and more uniform heat distribution, leading to better casting results and reduced cycle times. This ultimately translates to improved productivity and cost savings for manufacturers.

The Carbon Graphite Casting Mould is also well-suited for producing complex and intricate parts with fine details and intricate geometries. Its ability to withstand high temperatures and pressures allows for the precise replication of intricate features, leading to superior casting quality and dimensional accuracy.

In addition to its exceptional material properties, the company behind the Carbon Graphite Casting Mould also offers a range of customization options to meet the specific needs of different applications. This includes the ability to tailor the mould's design, dimensions, and surface finishes to achieve optimal casting results for a variety of components.

The use of Carbon Graphite Casting Mould is already making an impact across various industries, including automotive, aerospace, and industrial manufacturing. The mould has been successfully employed in the production of critical components such as engine parts, turbine blades, and intricate metallic structures, where the demand for high-performance and complex geometries is paramount.

The adoption of Carbon Graphite Casting Mould has also been lauded for its positive environmental impact. The lightweight and durable nature of carbon graphite reduces the overall material usage and energy consumption in the manufacturing process, contributing to a greener and more sustainable production practice.

As the manufacturing industry continues to evolve, innovative solutions such as the Carbon Graphite Casting Mould will play a crucial role in meeting the growing demand for high-performance and complex components. With its exceptional material properties, customization options, and environmental benefits, the mould is set to become an indispensable tool for manufacturers seeking to push the boundaries of what is possible in the realm of casting technology.

In conclusion, the Carbon Graphite Casting Mould represents a significant advancement in manufacturing technology, offering a range of benefits including improved casting quality, enhanced productivity, and environmental sustainability. With its widespread applicability across different industries, it is poised to redefine the way complex components are produced, setting new standards for quality and efficiency in the manufacturing sector.

Company News & Blog

Digital Control Metal Melting Furnace with Graphite Crucible for DIY Projects

Electric Melting Furnace Forge Metal DIY Digital Control Graphite Crucible: A Must-Have for Metalworking EnthusiastsMetalworking enthusiasts always strive to create high-quality finished products that meet their exact specifications. However, achieving a perfect end product often requires the use of specialized tools and equipment. One such tool is an electric melting furnace forge metal DIY digital control graphite crucible. This device has revolutionized the metalworking industry by making it easier to melt and shape metals with precision and accuracy.The electric melting furnace forge metal DIY digital control graphite crucible is a powerful and versatile tool that can handle different types of metals, including precious metals such as gold, silver, and platinum. It is also perfect for melting other types of metals like copper, brass, and aluminum, making it an essential tool for metalworking enthusiasts and professionals alike.This advanced technology furnace is equipped with a digital control temperature system that allows users to set and maintain precise temperatures according to their specific metalworking requirements. The device's digital control system eliminates guesswork from the melting process, ensuring that your metal melts evenly and at a consistent temperature. This feature not only helps prevent wastage but also ensures a higher quality of work.The furnace's graphite crucible is another feature that sets it apart from traditional furnaces. Graphite is an excellent material for melting metals because it has high thermal conductivity, making it ideal for transferring heat efficiently. This ensures that the metal is melted evenly and efficiently, resulting in high-quality end products. Additionally, the graphite crucible is durable and resists chemical corrosion, making it last longer than traditional metal crucibles.This electric melting furnace forge metal DIY digital control graphite crucible is easy to install and use. The device is compact and portable, making it perfect for use at home, in the workshop, or on the go. Its digital control system is user-friendly, and its instructions are straightforward, making it easy to operate, even for beginners.Quality is at the forefront of the manufacturers' minds when producing this device. It is made with durable and high-quality materials to ensure longevity, efficiency, and performance. The manufacturers also offer a warranty that covers manufacturing defects, giving customers peace of mind when using the device.In conclusion, the electric melting furnace forge metal DIY digital control graphite crucible is a must-have tool for metalworking enthusiasts and professionals who want to produce high-quality end products. Its compact size, precise digital control system, and graphite crucible make it ideal for melting and shaping metals with precision and efficiency. The product's durability, longevity, and warranty ensure that you get value for your money. Purchase one today and take your metalworking skills to the next level.

Isostatic Graphite Industry: Growth, Usage, and Properties – Global & China Insights, 2018-2022

Isostatic graphite: The specialty graphite with exceptional propertiesIsostatic graphite, also known as molded graphite, is a type of high-end specialty graphite that has multiple exceptional properties. It differs from other types of graphite, as it is produced by isostatic pressing of graphite particles instead of the traditional extrusion or compression processes.The resulting material has a unique microstructure that gives it unmatched mechanical strength, high thermal conductivity, low thermal expansion coefficient, excellent electrical conductivity, and chemical inertness. Therefore, isostatic graphite has numerous applications across different industries, such as aerospace, semiconductor, nuclear, and metallurgy, among others.China is one of the leading producers and consumers of isostatic graphite, with a significant increase in demand over the last few years. The country has abundant graphite resources and advanced technologies to produce high-quality isostatic graphite, which is widely used for manufacturing graphite electrodes, crucibles, molds, and heating elements.China Isostatic Graphite Pot: The Innovative Solution for High-Temperature ApplicationsThe China Isostatic Graphite Pot is a new and innovative product that is made from high-quality isostatic graphite and has excellent performance in high-temperature applications. The pot is specially designed to withstand extreme temperatures and harsh chemical environments, making it the perfect solution for various industrial processes.One of the main advantages of the China Isostatic Graphite Pot is its ability to resist thermal shock and oxidation, which is critical in applications involving the melting and casting of metals and alloys. Its superior thermal stability also means that it can maintain its structural integrity and dimensional accuracy over a wide range of temperatures, even up to 3000°C.Moreover, the China Isostatic Graphite Pot has a low porosity and high density, which enables it to have excellent mechanical strength and wear resistance. It is also chemically inert, ensuring that it does not contaminate the molten metal or alloy during the casting process.Applications of China Isostatic Graphite PotThe China Isostatic Graphite Pot has numerous applications in different industries, including:1. Metallurgy: The pot is used for melting and casting various metals and alloys, such as steel, iron, copper, aluminum, and titanium, among others.2. Semiconductor: The pot is used for growing single crystals of silicon and other semiconductors, which are used in electronic devices.3. Aerospace: The pot is used for manufacturing rocket nozzles, heat shields, and other components that require high-temperature resistance.4. Chemical: The pot is used for carrying out chemical reactions that involve high temperatures and harsh chemicals.ConclusionIsostatic graphite is a unique and valuable material that has numerous applications across different industries. The China Isostatic Graphite Pot is a new and innovative solution that offers exceptional performance in high-temperature applications, especially in the metallurgy, semiconductor, aerospace, and chemical industries. With its superior thermal stability, mechanical strength, and chemical inertness, the China Isostatic Graphite Pot is an excellent investment for any industrial process that requires high-temperature resistance and dimensional accuracy.

Premium Graphite Mold For Fiberglass Manufacturing: Superior Quality and Durability

Graphite Mold For Fiberglass Takes Manufacturing to the Next Level(Graphite Mold For Fiberglass) is revolutionizing the manufacturing industry with its innovative and high-quality graphite molds for fiberglass production. The company has been a leader in the industry for over a decade, providing top-of-the-line products to a wide range of clients in various sectors, including automotive, aerospace, marine, and construction.The molds manufactured by (Graphite Mold For Fiberglass) are known for their durability, precision, and efficiency. They are designed to withstand high temperatures and pressures, making them ideal for the production of fiberglass components that require intricate and complex shapes. The company's state-of-the-art manufacturing facilities allow them to produce molds of various sizes and specifications, catering to the unique needs of each client.(Graphite Mold For Fiberglass) prides itself on its commitment to quality and customer satisfaction. The company works closely with its clients to understand their specific requirements and ensures that the molds are tailored to meet their exact specifications. This personalized approach has earned (Graphite Mold For Fiberglass) a stellar reputation in the industry, with many clients commending the company for its reliability and consistency in delivering high-quality products.The use of graphite molds for fiberglass production offers several advantages over traditional methods. Graphite is an excellent conductor of heat and can withstand extreme temperatures, making it an ideal material for creating molds for fiberglass production. This results in faster cycle times and improved efficiency in the manufacturing process, ultimately leading to cost savings for clients.In addition to its superior thermal properties, graphite molds also offer exceptional dimensional stability, ensuring that the final fiberglass components maintain their precise shape and dimensions. This level of precision is crucial for industries such as aerospace and automotive, where tight tolerances are essential for optimal performance.Furthermore, graphite molds are highly resistant to wear and tear, resulting in a longer lifespan compared to traditional molds. This durability means that clients can expect a higher return on their investment, as the molds require less frequent replacement and maintenance.(Graphite Mold For Fiberglass) is at the forefront of research and development in the field of graphite mold manufacturing. The company continually invests in innovative technologies and processes to improve the performance and capabilities of its molds, staying ahead of industry trends and meeting the evolving needs of its clients.The use of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows (Graphite Mold For Fiberglass) to create highly intricate and complex mold designs with exceptional accuracy. This digital design and manufacturing approach also streamlines the production process, reducing lead times and enhancing overall efficiency.As sustainability and environmental responsibility are increasingly important considerations for businesses, (Graphite Mold For Fiberglass) is committed to minimizing its environmental impact. Graphite is a highly recyclable material, and the company adheres to strict recycling and waste management practices, ensuring that its manufacturing processes are as eco-friendly as possible.The superiority of graphite molds for fiberglass production has led to a surge in demand for (Graphite Mold For Fiberglass)'s products. The company has seen significant growth in recent years, expanding its client base and establishing itself as a trusted partner for businesses seeking high-quality and reliable graphite molds.(Graphite Mold For Fiberglass) continues to set the standard for excellence in the manufacturing industry, delivering cutting-edge solutions that empower its clients to achieve their production goals with unparalleled efficiency and precision. With a steadfast commitment to quality, innovation, and customer satisfaction, (Graphite Mold For Fiberglass) is poised to remain a leader in the field for years to come.

High-Quality Graphite Products - Blocks, Rods, Molds, Powders, Sheets and Boats | Made-in-China.com

China Graphite Boat Manufacturer: All You Need to KnowGraphite has been widely used in various industries because of its unique characteristics, including high temperature resistance, high electrical conductivity, and excellent thermal conductivity. As a result, it has become one of the most sought-after materials.Qingdao Weijie Graphite Co., Ltd. is a professional manufacturer of graphite block, rod, mold, powder, sheet, and boat. It has been producing high-quality graphite products for more than ten years, and its products are exported to more than 50 countries worldwide.In this blog, we will take a closer look at graphite boats and why Qingdao Weijie Graphite Co., Ltd. is considered as the best China graphite boat manufacturer.What is a Graphite Boat?A graphite boat is a container made from graphite material and is used in various industries for high-temperature applications. Because of its high-temperature resistance, it is used as a furnace tray, boat, or crucible for carrying molten metal or other substances.Graphite boats are made from high-purity graphite, which gives them excellent thermal shock resistance, low thermal expansion, and high-temperature stability. They come in different sizes and shapes, depending on their usage.Why choose Qingdao Weijie Graphite Co., Ltd. as your Graphite Boat Manufacturer?Qingdao Weijie Graphite Co., Ltd. is a professional China graphite boat manufacturer that offers a wide range of graphite boats suitable for various industries. The company uses only the best materials from reputable sources to produce high-quality products that meet international standards.Here are some reasons why you should choose Qingdao Weijie Graphite Co., Ltd. as your China graphite boat manufacturer:1. High-Quality ProductsQingdao Weijie Graphite Co., Ltd. uses state-of-the-art technology and modern production facilities to ensure that its products are of the highest quality. The company has a strict quality control process that ensures every product is thoroughly inspected before being shipped to customers.2. Customized OptionsThe company offers a wide range of customization options to suit different customer needs. It can produce graphite boats that are unique in size, shape, and other specifications to meet customer-specific requirements.3. Competitive PricingQingdao Weijie Graphite Co., Ltd. offers its products at affordable prices, making them accessible to companies of all sizes. Despite the affordable prices, the company does not compromise on quality, making it an excellent value for money.4. Excellent Customer ServiceThe company has a team of highly trained and experienced customer service representatives who are always available to assist customers with any queries or concerns. They provide prompt and professional responses to ensure that customers are satisfied with the service.ConclusionGraphite boats are essential components in various high-temperature industries, including the semiconductor industry, metallurgy industry, and chemical industry. Choosing the right manufacturer is crucial when it comes to quality, customization, and pricing.Qingdao Weijie Graphite Co., Ltd. is a reputable China graphite boat manufacturer that produces high-quality graphite boats at competitive prices. The company offers customization options to meet different customer needs and has a team of excellent customer service representatives to provide support.If you are looking for a reliable China graphite boat manufacturer, contact Qingdao Weijie Graphite Co., Ltd. today and get the best products for your industry.

Discover the Benefits and Applications of Exothermic Welding Graphite Molds

Title: Groundbreaking Exothermic Welding Technology Revolutionizes the Electrical IndustryIntroduction:In a pioneering move, Company X has successfully introduced an innovative exothermic welding graphite mold that promises to revolutionize the electrical industry. This groundbreaking technology not only ensures secure and durable connections for various electrical applications but also enhances safety by minimizing the risk of fires or electrical faults. With its commitment to delivering cutting-edge solutions, Company X has once again established itself as a leading player in the market.Background:Exothermic welding, also known as thermite welding, is a tried and tested technique used for decades to create reliable electrical connections. Traditional exothermic welding involves using a graphite mold that acts as a perfect conductor for the welding process. It facilitates the creation of a permanent, high-strength, and low-resistance electrical connection, thereby ensuring a robust and long-lasting connection.Company X's Introduction:Company X, a renowned leader in the electrical industry, has recently introduced its state-of-the-art exothermic welding graphite mold. With decades of experience in developing cutting-edge products, Company X has continually focused on enhancing safety, reliability, and efficiency in electrical installations.The newly designed graphite mold by Company X incorporates several cutting-edge features that make it stand out from its competitors. The mold's advanced design allows for precise and effortless alignment during the welding process, resulting in consistent and reliable connections every time. Furthermore, the materials used in the mold offer exceptional resistance to corrosion, ensuring its longevity and durability.Advantages of Company X's Exothermic Welding Graphite Mold:1. Enhanced Safety: Ensuring secure electrical connections is of paramount importance, and Company X's exothermic welding graphite mold is designed with safety in mind. The mold's exceptional heat resistance and non-flammable properties minimize the risk of fires or other electrical faults, enhancing safety in all electrical installations.2. Durability: The graphite mold's unique construction materials provide unparalleled durability, ensuring that the connections created are long-lasting and resistant to environmental factors such as moisture, corrosion, and heat.3. Time and Cost Efficiency: Company X's graphite mold offers an efficient and time-saving welding process, reducing labor costs and allowing for quick installations. The precise alignment design eliminates the need for repeated attempts, resulting in reduced material waste.4. Versatility: This innovative mold can be used in various applications, ranging from electrical grounding and lightning protection systems to power distribution networks. Its adaptability makes it a versatile choice for electrical contractors and utility companies.Conclusion:Company X's introduction of its groundbreaking exothermic welding graphite mold has brought a new level of safety, reliability, and efficiency to the electrical industry. With an unwavering commitment to innovation and excellence, Company X continues to provide cutting-edge solutions that push the boundaries of technological advancement. Electrical professionals can now benefit from a time-saving, cost-effective, and secure welding process, thanks to the exceptional features of Company X's graphite mold. As the industry adopts this game-changing technology, it is poised to set new standards for electrical connections, ensuring a safer and more reliable future.

Easy Guide for Sourcing Quality Heater Components at Affordable Prices

As the world continues to evolve with technology, so do the ways we manage our homes. One important aspect of any household is the heating system, which often relies on heater parts for optimal functioning. Heater parts play a crucial role in maintaining a comfortable temperature inside homes, even during the coldest days of winter. That's why we are excited to announce the launch of our new line of heater parts, designed to offer customers reliable performance while ensuring maximum efficiency.Our company has been in the HVAC industry for over a decade, serving customers with pride and dedication. During this time, we have come to appreciate the importance of quality heating systems, and how they can make a significant impact on the comfort of our clients' homes. As we continually expand and improve our products, our goal remains focused on delivering top-notch, affordable solutions to meet all heating needs.Our new range of heater parts was developed to emphasize durability, affordability, and compatibility. The line features various heater parts, including gas valves, pressure switches, blowers, igniters, flame sensors, and other crucial components. We have ensured every product adheres to our strict quality control processes, guaranteeing the highest performance standards for our customers.Our gas valves are designed to work with all types of heaters, no matter the size or type. We understand the importance of gas valves, which are not only crucial to the functioning of the heating system but also safety. Our gas valves feature advanced technology, including smart controls, to provide precise gas regulation, ensuring that every user remains safe while enjoying their heating systems.Our pressure switches are essential to safety because they monitor water and gas pressure levels, ensuring that your heating system only operates when conditions are safe. Our switches are reliable, durable, and compatible with many different heating systems brands. Our switches have passed rigorous testing and adhere to industry standards, ensuring everyone's safety and comfort.Our blowers are designed to improve the heating system's performance, which is an essential part of generating and circulating warm air throughout homes. Our blowers come in different sizes, capacities, and types, ensuring there is a suitable option for all heating system users. Our blowers are easy to install, use little electricity, and are designed to last for years.Our igniters and flame sensors are crucial components that ensure safe ignition and heating of the air in your homes. They use advanced technology that quickly lights the pilot light and ignites the burner while maintaining flame safety standards. Our flame sensors consistently monitor the furnace's flame, which helps safeguard against explosions, gas leaks, and fire incidents. They ensure that the furnace ignites and runs smoothly, providing maximum comfort and safety.Finally, our new line of heater parts is designed to work with major heating system manufacturers' brands. This compatibility means that our customers can confidently purchase our products without fear of incompatibility with their systems.In conclusion, our new line of heater parts marks a significant milestone in our company's continued commitment to advancing the heating and cooling industry. We continue to work tirelessly to provide top-quality products that meet the highest performance, efficiency, and safety standards. Our new range of heater parts provides our customers with affordable and high-quality solutions to help keep their homes cozy and inviting, regardless of the weather outside.

Highly Effective Graphite Pad for Improved Performance and Durability

Innovative Graphite Pad Revolutionizes Thermal Management in Electronics(Company) is proud to introduce a game-changing solution for thermal management in electronics with their latest Graphite Pad. This cutting-edge product is set to revolutionize the industry with its superior heat dissipation capabilities, making it an essential component for high-performance electronic devices.The Graphite Pad is designed to effectively transfer heat away from electronic components, ensuring optimal thermal performance and reliability. Its advanced graphite material offers excellent thermal conductivity, making it an ideal solution for applications that require efficient heat dissipation. Whether it’s for smartphones, laptops, LED lighting, or automotive electronics, this innovative pad is poised to set a new standard for thermal management in electronic devices.One of the key advantages of the Graphite Pad is its flexibility and adaptability to various shapes and sizes, allowing for seamless integration into a wide range of electronic products. Unlike traditional thermal interface materials, such as thermal paste or pads, the Graphite Pad eliminates the need for messy application and cleanup, offering a more convenient and efficient solution for manufacturers.The Graphite Pad’s exceptional thermal conductivity properties also result in lower operating temperatures for electronic devices, which not only improves performance but also extends the lifespan of critical components. This is particularly crucial for high-power applications where thermal management is a significant challenge.Furthermore, (Company)’s Graphite Pad is designed to meet the stringent thermal performance requirements of modern electronic devices, ensuring that it can effectively address the heat dissipation needs of the latest technology innovations. Its reliability and durability make it an ideal choice for demanding applications where thermal management is a critical factor in product performance.In addition to its outstanding thermal properties, the Graphite Pad also offers excellent electrical insulation, making it suitable for applications where electrical isolation is necessary. This dual functionality further enhances its value as a versatile and practical solution for electronics manufacturers.Manufactured with high-quality materials and precision engineering, the Graphite Pad exemplifies (Company)’s commitment to excellence and innovation in thermal management solutions. The company’s extensive experience and expertise in the field of electronic materials have enabled them to develop a product that not only exceeds industry standards but also anticipates the evolving needs of the electronics market.(Company)’s Graphite Pad is positioned to make a significant impact on the electronics industry, offering a next-generation solution for thermal management that addresses the challenges of modern electronic devices. With its superior thermal conductivity, flexibility, and reliability, this innovative product is set to become an indispensable component for electronic manufacturers seeking to enhance the performance and reliability of their products.As the demand for higher-performing electronic devices continues to grow, (Company)’s Graphite Pad represents a timely and invaluable solution for manufacturers looking to stay ahead of the curve in thermal management technology. By leveraging the benefits of this innovative product, electronics manufacturers can achieve enhanced performance, increased reliability, and extended product lifespans, thereby meeting the exacting demands of today’s discerning consumers.In conclusion, (Company)’s Graphite Pad stands as a testament to the company’s dedication to advancing thermal management technology in the electronics industry. Its exceptional thermal conductivity, reliability, and adaptability make it a game-changing solution for manufacturers seeking to elevate the performance and longevity of their electronic products. With its introduction, (Company) reaffirms its position as a leader in innovative electronic materials and a driving force behind the next wave of technological advancements in thermal management.

An Introduction to Evaporation Crucibles: Why They Are Important in Many Industries

Evaporation Crucible Company Develops Innovative Technology for Material Processing NeedsEvaporation Crucible, a company that focuses on the design and manufacturing of crucibles, has been innovating its technology to better meet customers' material processing needs. For over a decade, the company has been providing high-quality crucibles to various industries that require exceptional performance and accuracy in their material processing. With its cutting-edge technology, Evaporation Crucible has taken the next step in advancing its service to its clients.Evaporation Crucible's state-of-the-art crucibles are known for their exceptional quality and performance, making them a top choice for various industries. From metal casting to semiconductor production, its customers rely on the company’s high-quality products for their material-processing needs. To better serve its clients, the company has expanded its product line to include a wider range of materials, designs, and sizes.One of the major innovations in Evaporation Crucible's technology is its advanced ceramic processing capabilities. The company has developed a proprietary method for producing complex ceramic shapes and components with high precision, ensuring consistency and quality in every product. Its advanced ceramic manufacturing process has significantly reduced lead times for its customers, allowing them to innovate and stay ahead of the competition.Not only does Evaporation Crucible offer high-quality products, but it also has an exceptional team that works closely with clients to ensure their specific needs are addressed. Comprising of experienced engineers, the company’s team provides technical support and helps clients choose the right materials based on their specific application requirements. Furthermore, the team works diligently to ensure timely and efficient deliveries, making sure that customers receive their products quickly and efficiently.The company also prioritizes safety and the environment. To that end, it has developed eco-friendly technology, minimizing waste and reducing its carbon footprint. Its recycling program also ensures that used crucibles are safely disposed of and that valuable materials are salvaged from the waste.The CEO of Evaporation Crucible, John Smith, expressed his excitement about the company's new technology and its potential impact on the industry. "Our advanced ceramic processing capabilities have opened up new possibilities for our customers, enabling them to create more complex and intricate shapes and components with high precision,” Smith said. “By focusing on high-quality materials, efficient processes, and excellent customer service, we have made it our mission to elevate the material processing industry, and we are excited about the endless possibilities and potential partnerships that this advancement creates."As the material processing industry continues to evolve and grow, Evaporation Crucible is poised to stay ahead of the curve with its commitment to innovation. Its focus on advanced ceramic processing technology, reliable customer service, safety, and environmental sustainability is a testament to the company’s vision and dedication to its clients. Evaporation Crucible's expansion of its product line is a reflection of its commitment to providing a diverse range of advanced materials that can meet the unique requirements of modern technology. With its exceptional team of experienced engineers, the company is well-positioned to provide innovative solutions to companies' specific material processing needs. They are truly the new leaders of innovation in the industry.

China Manufactures High-Quality Graphite Crucibles for Aluminium

In the world of high-temperature materials and industrial manufacturing, graphite crucibles have emerged as an essential material that can withstand extreme temperatures and pressures while maintaining highly desirable thermal properties. In recent years, China has emerged as a leader in the production of such graphite crucibles, particularly those that are specifically designed for aluminum production.One company at the forefront of this innovation is one of the largest producers of graphite crucibles in China. Founded in the early 1990s, the company has grown to become a global supplier of graphite products, including crucibles, electrodes, and parts.One of its most popular products is its graphite crucibles for aluminum production. At first glance, these crucibles may look like any other crucible used in the manufacturing process, but they are specifically designed to withstand the high temperatures needed to produce aluminum. To achieve this, the company's crucibles are made from a special type of graphite that has been heat-treated to make it extremely strong and resilient.While the exact composition of each crucible's graphite blend is a closely guarded secret, the company has revealed that it is made from a combination of natural and artificial graphite. This blend allows the crucibles to withstand the extreme temperatures needed to melt aluminum, while also providing excellent thermal insulation to keep the metal at the ideal temperature for casting.In addition to their unique blend of graphite, the company's crucibles are also designed to be highly durable, with a service life that is up to five times longer than other crucibles on the market. This is achieved through a combination of high-quality materials, precise manufacturing techniques, and strict quality control procedures.The company's graphite crucibles for aluminum production are used by manufacturers all over the world, including many of the world's largest aluminum producers. These crucibles have become an essential component in the production of aluminum, allowing manufacturers to produce high-quality aluminum products more efficiently and at a lower cost.However, the company's commitment to quality doesn't stop at its products. The company also places a strong emphasis on customer service, with a dedicated team of experts available to provide technical support and guidance to customers around the world.With its high-quality graphite crucibles for aluminum production and dedication to customer service, the company has become a leader in the global graphite industry. As demand for high-quality aluminum continues to grow, the company's products and expertise will undoubtedly play an increasingly important role in the manufacturing process.

High-Quality Carbon Graphite Plates for Various Industrial Applications

Carbon Graphite Plates Introduced by Leading Company to Meet Growing Industrial DemandsAs industrial production continues to evolve and become more advanced, there is an increasing need for materials that can provide efficient performance under extreme environments. Carbon graphite plates have become popular substitutes for traditional materials due to their strength, durability, and excellent thermal conductivity. To meet the growing demand for these products, a leading company (name removed) has introduced a new line of Carbon Graphite plates that offer exceptional performance for various industrial applications.Carbon graphite has been a preferred material in a wide range of fields such as aerospace, automotive, electrical, and energy. One reason for their popularity is their ability to withstand high temperatures, corrosion, and wear. The material is also chemically inert, making it resistant to most chemicals, and has a low coefficient of thermal expansion. The properties of carbon graphite make them ideal for use in high-performance applications that encounter high mechanical, thermal, and chemical stresses.The new range of carbon graphite plates by (name removed) are made using advanced processing technologies, ensuring high functional performance and consistency in quality. The plates are made using the highest grade raw materials, providing excellent thermal and mechanical strength, low thermal expansion rate, and high dimensional stability. The exceptional properties of these plates have made them ideal for use in various industrial applications.One of the notable applications of carbon graphite plates is in the aerospace industry, where they are used in fuel cell components, heat exchangers, and other high-performance parts. The plates' exceptional thermal conductivity and dimensional stability make them ideal for use in advanced thermal management systems that provide efficient cooling solutions.Another notable application of carbon graphite plates is in the semiconductor industry. The material's low thermal expansion rate and low coefficient of friction have made them ideal for use in high-precision and high-speed equipment such as bearings, seals, and sliding surfaces. The plates' excellent resistance to corrosion and wear have made them ideal for use in harsh chemical environments.The new range of Carbon graphite plates (name removed) has introduced will cater to different customers' needs, ensuring that the company remains a leading supplier of high-performance materials. The company provides customized solutions tailored to specific industrial applications' needs, ensuring that customers can have the best options for their projects.(name removed) has been known for providing high-performance materials for various industrial applications. The company has a team of experts dedicated to developing and providing products that can meet the most demanding requirements of modern industries. The company has adopted advanced technologies and processes, ensuring that their products have consistent quality, performance, and durability.In conclusion, the introduction of new carbon graphite plates by (name removed) will provide an exceptional solution for various industrial applications. The plates' unique properties make them ideal for use in high-performance equipment, which requires efficiency, reliability, and durability. The company's commitment to providing customized solutions for different applications ensures that customers can get the best results for their projects. With the increasing demand for high-performing and sustainable materials, we can expect (name removed) to continue developing new products that would meet the industry's ever-evolving needs.