High-quality Graphite Box for Anode Powder: A Complete Guide

By:Admin

The demand for lithium-ion batteries is rapidly increasing with the growing popularity of electric vehicles, portable electronic devices, and energy storage systems. To meet this demand, the production of anode powder, a key component of lithium-ion batteries, is also rising. However, the traditional methods of producing anode powder are often associated with high energy consumption and environmental impact. In response to this challenge, {company name} has developed a sustainable solution - the Graphite Box for Anode Powder - that aims to revolutionize the battery production industry.

{company name} is a leading manufacturer of advanced materials for various industries, including energy storage, electronics, and aerospace. The company has a strong focus on research and development, aiming to create innovative solutions that address the environmental and sustainability challenges of modern industries. The Graphite Box for Anode Powder is one such innovation that showcases {company name}'s commitment to sustainable manufacturing practices.

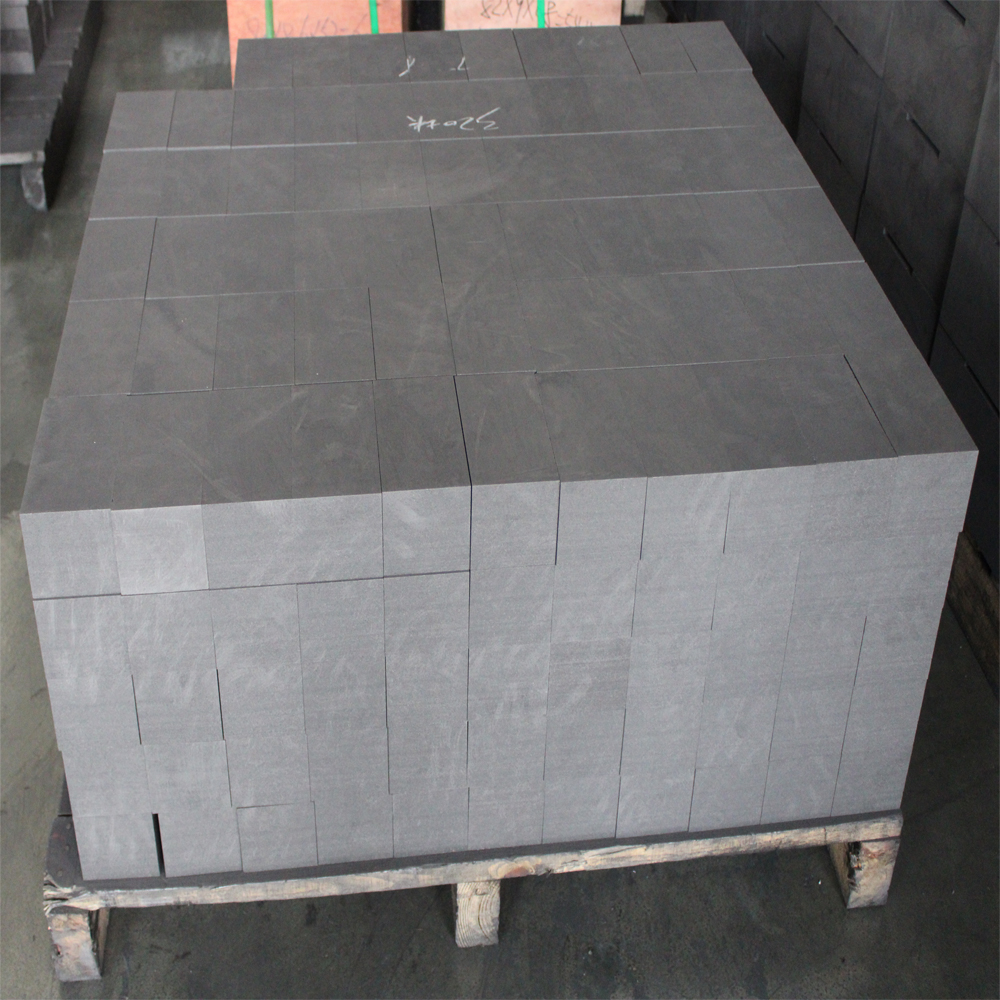

The Graphite Box for Anode Powder is designed to improve the production process of anode powder by utilizing graphite as a crucial component. Graphite is known for its exceptional thermal and electrical conductivity, making it an ideal material for high-temperature applications such as the production of anode powder. The box is specifically engineered to provide a controlled environment for the synthesis of anode powder, ensuring high quality and consistency in the final product.

One of the key advantages of the Graphite Box for Anode Powder is its energy efficiency. Traditional methods of anode powder production often involve high-temperature processes that consume a significant amount of energy. In contrast, {company name}'s innovative solution minimizes energy consumption by utilizing the thermal conductivity of graphite to maintain the required temperature within the production environment. This not only reduces the operational costs for manufacturers but also contributes to a more sustainable and eco-friendly production process.

Furthermore, the use of the Graphite Box for Anode Powder contributes to the reduction of greenhouse gas emissions in the production of lithium-ion batteries. As the global focus on sustainability and environmental impact intensifies, manufacturers are increasingly seeking innovative solutions to minimize their carbon footprint. The implementation of the Graphite Box for Anode Powder aligns with this trend, offering a more sustainable approach to battery production that supports the broader goal of mitigating climate change.

In addition to its environmental benefits, the Graphite Box for Anode Powder also enhances the performance and reliability of lithium-ion batteries. The controlled production environment ensures the uniformity and purity of the anode powder, ultimately leading to improved battery performance and longevity. This is particularly significant in the context of electric vehicles and energy storage systems, where the reliability and efficiency of lithium-ion batteries are critical for the overall performance of the applications.

{company name} aims to collaborate with battery manufacturers and research institutions to further optimize the Graphite Box for Anode Powder and promote its widespread adoption across the industry. By partnering with key stakeholders, {company name} seeks to drive innovation in battery production and contribute to the advancement of sustainable energy technologies.

In conclusion, the Graphite Box for Anode Powder represents a significant step towards sustainable battery production. {company name} has demonstrated its commitment to environmental responsibility and innovation by developing this advanced solution. As the demand for lithium-ion batteries continues to surge, the industry is poised to benefit from the adoption of sustainable manufacturing practices, with the Graphite Box for Anode Powder paving the way for a more sustainable and efficient future.

Company News & Blog

Experts Share Tips on Making Graphite Molds for Precision Manufacturing

Vancouver, Canada - A leading graphite mold manufacturer has announced a new addition to its product line that promises to further solidify its position as a top player in the industry. The company, which specializes in producing high-quality graphite molds, has unveiled its latest product offerings that are geared towards providing customers with even more options for their applications.Graphite molds are an essential part of the manufacturing process for a wide range of industries, including the automotive, aerospace, and medical industries. They are used to create intricate and precise shapes, as well as the replication of complex designs. The company's graphite molds have long been known for their durability, strength, and precision, making them a favorite among industry professionals and manufacturers.The addition of these new products is set to broaden the company's reach and enhance its offerings to customers. The company has always been at the forefront of innovation in the industry, constantly adapting to new technologies and trends to stay ahead of the competition. The new graphite molds are no different, with a focus on precision, accuracy, and quality."Our new products are designed with our customers in mind," said the company spokesperson. "We understand that each client has unique needs, and our goal is to provide them with the best possible solutions to meet their requirements. We are confident that our new graphite molds will do just that."The new graphite molds come in a variety of shapes and sizes, making them suitable for different applications. The company has ensured that every mold meets the strictest quality standards to ensure maximum efficiency and effectiveness during the manufacturing process.Besides the quality and precision of the molds, the company has always placed great emphasis on customer service. In a highly competitive industry, customer satisfaction is crucial, and the company is well aware of that. The company spokesperson added that "our customers are at the heart of everything we do. We strive to exceed their expectations by providing them with the best products and services possible."The company's commitment to excellence has earned them a reputation as a dependable and trustworthy partner in the industry. They have worked with some of the biggest names in the business and have consistently delivered quality products and services that meet the client's needs."We are proud of our heritage and our contribution to the industry," said the spokesperson. "Our goal is to continue to build on that legacy and remain at the forefront of innovation in the graphite mold industry."With the unveiling of these new products, the company looks set to continue to dominate the industry and cement its position as a top manufacturer of graphite molds. The company's growth is a testament to its commitment to quality, innovation, and customer service, values that have earned it a loyal customer base and a reputation as a leading player in the industry. For customers looking for a reliable and high-quality graphite mold supplier, this company is worth considering. With its impressive track record, a focus on product innovation, and unmatched customer service, they are a dependable partner for manufacturing businesses of all sizes.

Small Electric Foundry for Bronze Casting: Tips and Techniques for Successful Results

Electric Foundry for Small Bronze Casting – Crucible for Melting BronzeBronze casting has been around for thousands of years. It is an ancient method of creating beautiful objects of art. Today, modern technology has made it easier for people to attempt bronze casting on their own. This is where a small electric foundry comes in handy. In this article, we will discuss how to make a small foundry for melting tin bronze.First, let's talk about the materials we will need. The following items are essential for building a small foundry:1. Soft fire bricks – These bricks are used to build the walls of the foundry. They are designed to withstand high temperatures.2. Insulator – This is a high-temperature insulation material that is used to line the inside of the foundry. It keeps the heat inside the foundry and prevents it from escaping.3. Nichrome coil – This is a heating element that is used to provide the heat needed to melt the tin bronze.4. Crucible – This is a container used to melt the bronze. It must be made of a material that can withstand high temperatures and is resistant to corrosion.Now that we have the materials, let's get started on building the foundry. The first step is to build a frame with the soft fire bricks. The size of the frame will depend on the size of the crucible. The frame should be built to support the crucible and the insulator.Next, place the insulator inside the frame. The insulator should be cut to size and placed inside the frame. It should be wrapped around the sides and the bottom of the frame. The insulator is what will keep the heat inside the foundry.After the insulator is in place, wrap the nichrome coil around the outside of the insulator. The coil should be wrapped tightly and evenly around the entire foundry. It should be wired to a 240V 10amp socket. The coil is what will provide the heat necessary to melt the tin bronze.Once the coil is in place, it's time to add the crucible. The crucible should be placed inside the foundry and centered on the coil. It should be large enough to hold the amount of bronze you plan to melt. The crucible should be made of a material that can withstand high temperatures, such as graphite or ceramic.Finally, turn on the power to the coil. The heat should be gradually increased until the bronze is fully melted. Once the bronze is melted, it's ready for casting.ConclusionBuilding a small foundry for melting tin bronze is not a difficult task. With the right materials, it can be done easily at home. By using a soft fire brick frame, high-temperature insulation, a nichrome coil, and a crucible, you can create your own electric foundry. This will allow you to create beautiful bronze objects of art in the comfort of your own home. So, get started today and let your creativity flow!

Enhanced Efficiency: Discover the Benefits of a Customized Graphite Heater

Customized Graphite Heater: Enhancing Efficiency and Performance in Industrial Heating ApplicationsIn today's rapidly advancing world, industries are constantly seeking innovative solutions to meet their growing energy demands while reducing their carbon footprint. Graphite heaters have emerged as a game-changer in achieving efficient and sustainable heating in various industrial applications. One such groundbreaking solution is the Customized Graphite Heater developed by [Company Name], a pioneering leader in advanced heating technologies.[Company Name], founded in [year], has established itself as a reliable provider of cutting-edge heating solutions catering to diverse industries, including automotive, aerospace, electronics, and pharmaceuticals. With a relentless focus on research and development, the company has been instrumental in revolutionizing heating technology. The Customized Graphite Heater exemplifies their commitment to innovation, efficiency, and sustainability.Designed to meet the specific requirements of industrial heating processes, the Customized Graphite Heater offers unparalleled performance and versatility. With its exceptional thermal conductivity, low thermal mass, and uniform heating capacity, this heater enables precise temperature control and rapid heating, providing significant advantages over traditional heating methods.One key advantage of the Customized Graphite Heater is its efficiency in energy consumption. Its unique design maximizes heat transfer, resulting in reduced energy wastage. This not only saves costs for industries but also contributes to their sustainability goals by minimizing greenhouse gas emissions. Additionally, the heater's robust construction ensures durability, minimizing downtime and maintenance costs.Furthermore, the Customized Graphite Heater is designed to meet the specific needs of each client. The [Company Name] team works closely with customers to understand their heating requirements and devise tailored solutions that optimize performance and efficiency. Whether it's a high-temperature application or one requiring a large heating area, the Customized Graphite Heater can be customized to meet any challenge, ensuring seamless integration into existing systems.The heater's versatility extends to its compatibility with various industrial processes. From semiconductor manufacturing to chemical synthesis, the Customized Graphite Heater provides precise and uniform heating, resulting in improved product quality and reduced production time. Its ability to heat surfaces evenly, regardless of shape or size, makes it an ideal choice for industries seeking consistent and reliable heating solutions.Safety, a paramount concern in industrial heating, is addressed through the Customized Graphite Heater's unique design features. Incorporated thermal insulation safeguards surrounding components and ensures operator safety. The heater's resistance to thermal shock and high temperatures further enhances its reliability and minimizes the risk of failures or accidents.In addition to its industrial applications, the Customized Graphite Heater finds uses in research and development laboratories. Its ability to meet the rigorous demands of controlled experiments, such as material synthesis or thermal analysis, makes it an invaluable tool for scientists and researchers.As industries continue to demand more efficient heating solutions, the Customized Graphite Heater stands at the forefront of innovation, addressing the needs of a rapidly evolving world. [Company Name]'s commitment to excellence in heating technology ensures that customers receive reliable, cost-effective, and sustainable solutions that surpass their expectations.Looking ahead, [Company Name] remains dedicated to pushing the boundaries of heating technology, seeking new ways to optimize performance, enhance energy efficiency, and expand the applications of the remarkable Customized Graphite Heater. As industries embrace greener practices and sustainable manufacturing processes, this advanced heating solution promises to play a pivotal role in shaping a more sustainable future.[Company Name] continues to demonstrate its leadership and expertise in the field by delivering cutting-edge heating solutions that not only surpass industry standards but also contribute to a greener and more sustainable world. With the Customized Graphite Heater, industries can achieve unprecedented efficiency and performance in their heating applications while reducing their environmental impact.

Discovery's Latest Online Multiplayer Game Witnesses a Major Overhaul: Crucible

Title: Introducing a New Competitive Multiplayer Game: CrucibleIntroduction:In the rapidly growing gaming industry, modern players constantly crave new and immersive experiences. As gaming companies strive to meet these demands, one particular stand-out title promises to deliver an unparalleled gaming adventure. Developed by an industry-leading studio, Crucible is a highly anticipated competitive multiplayer game that combines stunning visuals, engaging gameplay, and unique character abilities. In this article, we will explore the captivating world of Crucible and discuss the innovative features that set it apart from other titles in its genre.Unveiling Crucible: Crucible, developed by a prominent gaming studio, is set to revolutionize the multiplayer gaming landscape. With a diverse range of playable characters and a vast, visually striking arena, Crucible aims to provide an exhilarating and competitive gaming experience. Players will be able to choose from a variety of characters, each with their own distinct abilities and playstyles, thus granting them a unique advantage in the intense battles that await.The Dynamic Arena:Crucible offers an array of dynamic environments that cater to different player preferences and strategies. From lush and verdant jungles to expansive deserts, each arena within Crucible is thoughtfully designed to provide players with an immersive and visually stunning battleground. These unique arenas will not only challenge players' tactical skills but also offer opportunities for strategic maneuvering, ensuring an adrenaline-filled and unpredictable gameplay experience.Innovative Gameplay Mechanics:What sets Crucible apart from other multiplayer games is its innovative gameplay mechanics. Crucible introduces a system called "The Heart of the Hives," where teams of players must compete to defeat powerful bosses and collect valuable resources. This feature introduces a compelling gameplay loop where teams must balance the risks of attacking enemy bosses with defending their own resources. Such mechanics foster intense cooperation and strategic decision-making amongst players.Furthermore, players will need to adapt to their surroundings and learning to interact with the environment to gain an advantage. From grappling hooks to teleportation, Crucible offers numerous ways for players to traverse the arena and surprise their opponents, adding an extra layer of excitement to the gameplay.Competitive Multiplayer Experience:Crucible is designed to offer players a remarkable competitive experience. In "Alpha Hunters" mode, teams of two players compete against each other, along with other AI-controlled opponents, in a last-team-standing battle. The challenge lies not only in defeating enemy players but also in forging alliances on the fly while keeping an eye on potential betrayals. In "Harvester Command" mode, two teams fight it out to control the resources on the map, requiring strong teamwork and coordination.Esports Potential:With its innovative gameplay mechanics and competitive nature, Crucible possesses the potential to become a highly influential esports title. The developer has already shown commitment to fostering a thriving esports community, organizing regular tournaments and providing platforms for aspiring professionals to showcase their skills. This further cements Crucible's status as a game that not only appeals to casual gamers but also possesses the depth and mechanics to support a thriving esports scene.Conclusion:Crucible represents a bold and exhilarating entry into the competitive multiplayer gaming space. With its visually striking arenas, diverse cast of characters, and innovative gameplay mechanics, Crucible promises an immersive and thrilling experience for gamers worldwide. As the anticipation builds for its release, gamers eagerly await the opportunity to explore the captivating world of Crucible and test their skills in this new gaming phenomenon.

Top Quality Graphite Crucibles for Aluminum Casting Available Now

Graphite Crucibles for Aluminium - The Crucial Commodity Driving the Global Metals IndustryThe global metals industry is witnessing a steady growth in demand for high-quality aluminium and its alloys, primarily driven by the rising requirements in the transportation and aerospace sectors. To meet this demand, aluminium manufacturers are required to use advanced technologies and quality materials. One such critical material used in the production of aluminium is graphite crucibles.Graphite crucibles are one of the most essential parts of the aluminium production process, and their correct selection plays a crucial role in maintaining the quality standards of the end product. In recent years, there has been a growing demand for graphite crucibles that are durable, heat-resistant, and can withstand the high temperatures required in the aluminium smelting process.A leading manufacturer of graphite crucibles for aluminium has been meeting this growing demand in the global market. This company, which has operations across Asia, Europe and North America, is known for its extensive range of quality graphite crucibles that cater to various stages of the aluminium production process. They offer an extensive range of high-performance graphite crucibles that are suitable for various furnace types, and can be customised according to specific customer requirements.The company has also been leveraging on advanced manufacturing technologies such as isostatic pressing, CNC machining, and computerized modelling to ensure consistent quality in their crucibles. They employ a rigorous quality control process at every stage of the production process to ensure that their products meet or exceed customer expectations.Moreover, this company has continued to invest in research and development to improve their product offerings and stay ahead of competitors. They have also been working closely with customers to develop customised solutions tailored to their unique manufacturing requirements.The company's graphite crucibles are highly sought after in the global market, with a considerable market share in key regions such as Asia, Europe, and North America. They serve a broad range of industries, including aerospace, automotive, construction, energy, and packaging.In recent years, the growth in demand for aluminium and its alloys has been driven by the increasing need for lightweight materials that offer high strength and durability. This trend has been particularly evident in the transportation and aerospace sectors, where manufacturers are required to reduce weight without compromising on safety or performance. Graphite crucibles have played a vital role in enabling manufacturers to meet these requirements and produce high quality aluminium and its alloys.Looking forward, the demand for graphite crucibles for aluminium is anticipated to continue growing, driven by the increasing adoption of lightweight materials in various industries. This trend is expected to result in new opportunities for the global graphite crucibles market, with manufacturers looking to expand their product offerings to cater to different stages of the aluminium production process.In conclusion, the graphite crucibles for aluminium market is a crucial commodity driving the global metals industry. The quality of graphite crucibles used in the aluminium production process is vital in ensuring consistent performance and quality of the end products. The leading manufacturer of graphite crucibles for aluminium has been meeting this demand by offering an extensive range of high-performance products, leveraging on advanced technologies and stringent quality control processes. With the increasing demand for lightweight materials, the graphite crucibles market is expected to grow, presenting new opportunities for manufacturers to cater to evolving customer requirements.

How Different Temperatures Affect Lithium Iron Phosphate-Graphite Battery Degradation: A Study on Charging and Discharging

Lithium Iron Phosphate (LFP) batteries are one of the most promising energy storage solutions for electric vehicles and home energy systems. These batteries are known for their high power density, long cycle life, and low risk of explosion. However, the performance of LFP batteries can degrade over time due to various factors, including temperature.In this article, we will discuss the effect of charging and discharging LFP batteries at different temperatures on their degradation. Specifically, we will focus on the role of graphite boat for Lithium Iron Phosphate Battery in this process.LFP batteries are composed of several components, including a cathode, an anode, a separator, and an electrolyte. The cathode material in LFP batteries is made of lithium iron phosphate, while the anode is typically made of graphite. Graphite is chosen as the anode material because of its ability to intercalate (store) lithium ions during charging and release them during discharging.During the charging process, lithium ions are transferred from the cathode to the anode, where they are stored in the graphite matrix. The charging process generates heat, which can increase the temperature of the battery. If the battery temperature exceeds a certain threshold, it can cause thermal runaway, leading to an explosion or fire.Similarly, during the discharging process, lithium ions are released from the anode and travel back to the cathode. This process also generates heat, which can increase the temperature of the battery. If the battery temperature drops too low, it can affect the efficiency of the battery, leading to a shorter cycle life.In general, it is recommended to charge LFP batteries at a moderate temperature range of 10°C to 30°C. Charging at higher temperatures can lead to accelerated degradation of the battery, while charging at lower temperatures can reduce the capacity of the battery. The same guidelines apply to discharging LFP batteries.The graphite boat for Lithium Iron Phosphate Battery has an important role to play in this process. The graphite boat acts as a container for the anode material, protecting it from external factors such as temperature, humidity, and dust. The quality of the graphite boat can significantly affect the performance of the battery. A high-quality graphite boat can provide better thermal insulation, reduce the thermal gradient within the battery, and prevent the leakage of lithium ions.In conclusion, the charging and discharging temperatures of LFP batteries play a crucial role in their degradation. Charging at moderate temperatures can help prolong the cycle life of the battery, while discharging at low temperatures can reduce its efficiency. The graphite boat for Lithium Iron Phosphate Battery is an essential component that can help protect the anode material from external factors and improve the overall performance of the battery.

Next-Generation Semiconductor Material Breaking Barriers in Electronics Industry

The rise of electric vehicles has put the spotlight on new technologies that can provide the power and efficiency required for this growing market. One of the key technologies that enable electric vehicles to travel long distances is power electronics. This technology is what allows electricity to be stored and transported in a vehicle's battery pack and converted into high-voltage power that can drive the motor. Silicon Carbide (SiC) is emerging as a key player in this space, thanks to its capabilities to deliver high-efficiency, high-reliability power electronics.SiC has been around for a long time as a semiconductor material, but only recently has it gained traction in the power electronics industry. This is because it offers many advantages over traditional semiconductor materials like silicon, which is currently in widespread use. One of the key advantages of SiC is that it can handle higher voltages than silicon, which makes it ideal for use in high-power devices like electric vehicle inverters.Another advantage of SiC is its ability to operate at higher temperatures than silicon, which means it can handle more power without failing. This is particularly important in electric vehicles, where the power electronics need to operate at maximum efficiency for extended periods. SiC's high thermal conductivity also helps to keep the temperature down, reducing the need for bulky cooling systems.SiC offers increased efficiency, with the ability to reduce power losses and extend the driving range of electric vehicles. This makes SiC an important technology for providing the power and performance needed for the next generation of electric vehicles. The market is responding to this demand, with SiC-related businesses intensifying R&D efforts on this emerging technology.One company that has been at the forefront of SiC development is {company}. The company has invested heavily in SiC technology, and is now one of the leading players in the SiC market. The company's products cover a range of SiC applications, including power devices, modules, and systems. They specialize in designing and manufacturing SiC products that meet the highest quality standards, specifically for the automotive and industrial markets.{Company} has developed a range of SiC products that are tailored to meet the growing demand for high-performance electric vehicles. Their products offer high efficiency, superior reliability, and an extended lifespan compared to traditional silicon-based products. Their SiC MOSFETs, in particular, have been designed specifically for the electric vehicle market, offering high performance, compact size, and high reliability.In addition to their SiC MOSFETs, {company} has a range of SiC products that are suitable for a variety of applications, including renewable energy, industrial automation, and high-frequency communications. Their SiC modules are highly efficient and compact, making them ideal for use in electric vehicle chargers, battery management systems, and other high-power applications.{Company} is also involved in the development of next-generation SiC technology, including the development of 200mm SiC wafer production technology. This technology is expected to significantly increase the supply of SiC wafers, making them more accessible and cost-effective for a wider range of applications.In conclusion, the demand for high-performance electric vehicles is driving the development of new power electronics Technologies. SiC is emerging as a key player in this space, offering high efficiency, superior reliability, and an extended lifespan compared to traditional semiconductor materials. Companies like {company} have invested heavily in SiC technology and are developing innovative products that meet the demands of the rapidly growing electric vehicle market. As the market continues to expand, SiC is expected to play an increasingly important role in driving the next phase of electric vehicle growth.

High-quality Graphite Crucibles Ideal for Melting Tin

Title: Graphite Crucible for Melting: A Reliable Choice for Industrial ApplicationsIntroduction:In various industrial sectors, the process of melting metals and other high-temperature applications plays a significant role. To ensure the success of these operations, the selection of high-quality equipment is essential. Graphite crucibles, popularly used for melting purposes, have gained immense popularity due to their exceptional properties and reliability. In this blog post, we will delve into the features, benefits, and applications of graphite crucibles for melting various materials in industrial settings.1. Understanding Graphite Crucibles:Graphite crucibles are specialized containers designed for holding and melting metals and other materials at extremely high temperatures. These crucibles are made from high-purity graphite, which exhibits remarkable thermal conductivity, corrosion resistance, and mechanical strength. The unique properties of graphite make it an ideal material for melting purposes.2. Key Features of Graphite Crucibles:2.1 High Thermal Conductivity:Graphite crucibles offer excellent heat transfer capabilities. Their high thermal conductivity ensures efficient and uniform melting of metals, eliminating the formation of hotspots, and providing consistent results.2.2 Corrosion Resistance:The chemical inertness of graphite makes crucibles highly resistant to corrosive agents. They can withstand aggressive molten materials, preventing contamination and maintaining the purity of the melted substance.2.3 Mechanical Strength:Graphite crucibles possess exceptional mechanical strength, allowing them to endure high temperatures and withstand thermal shock. This durability ensures longevity and enables multiple reuse cycles, making them a cost-effective choice.2.4 Excellent Insulation:Graphite crucibles exhibit excellent insulation properties, minimizing heat loss during melting operations. This feature increases energy efficiency and reduces operating costs.3. Benefits of Using Graphite Crucibles for Melting:3.1 Versatility:Graphite crucibles are compatible with a wide range of metals and materials. From precious metals like gold and silver to high-temperature alloys, graphite crucibles offer versatility for diverse melting requirements.3.2 Clean and Contamination-Free Melting:The non-reactive nature of graphite minimizes unwanted reactions, ensuring clean and pure melting processes. This aspect is crucial in industries like jewelry-making, where precise composition and flawless quality are imperative.3.3 Cost-Effective Solution:Graphite crucibles are highly durable and can withstand repeated use, making them a cost-effective solution in the long run. Additionally, their exceptional thermal conductivity reduces melting time and energy consumption, further contributing to cost savings.3.4 Easy Handling and Maintenance:Graphite crucibles are lightweight and easy to handle, simplifying the overall melting process and reducing the operational burden. Basic maintenance practices like periodic cleaning ensure the longevity of these crucibles.4. Applications of Graphite Crucibles:4.1 Metallurgy and Foundry:Graphite crucibles find extensive usage in the metallurgical and foundry industries for melting and casting various metals such as iron, steel, aluminum, and copper. Their thermal resistance and durability make them an ideal choice in these demanding operations.4.2 Jewelry-Making:The jewelry industry relies heavily on graphite crucibles for melting precious metals, enabling the creation of intricate and high-quality jewelry designs. The purity maintained during melting ensures flawless end products.4.3 Laboratory Applications:Graphite crucibles are widely employed in laboratory settings for experiments requiring high temperatures and controlled melting processes. Their reliability and consistency make them a trusted choice for scientific research and analysis.Conclusion:Graphite crucibles are a reliable and efficient solution for melting operations in diverse industries. Their exceptional properties, including high thermal conductivity, corrosion resistance, and mechanical strength, make them ideal for applications ranging from foundries to jewelry-making and laboratory experiments. With their cost-effectiveness and versatility, graphite crucibles continue to be the go-to choice for achieving efficient and contamination-free melting processes.

High-Quality Graphite Rods for Various Applications

1.85 Graphite Rods are the latest innovation in the field of graphite products. These high-quality rods are designed and manufactured to meet the demanding requirements of various industrial applications. With a strong focus on precision engineering and advanced materials, these graphite rods are set to revolutionize the industry and provide a competitive edge to businesses across the globe.The company behind the production of these extraordinary graphite rods, {Company Name}, has a long-standing reputation for excellence in the field of graphite manufacturing. With decades of experience and a dedication to innovation, they have become a trusted name in the industry. Their commitment to quality and customer satisfaction has made them a preferred supplier for a wide range of industries, including aerospace, automotive, energy, and more.The 1.85 Graphite Rods are a testament to {Company Name}'s expertise in materials science and engineering. These rods are engineered using the latest manufacturing techniques and cutting-edge technology, resulting in a product that is unmatched in its performance and durability. The exceptional properties of these graphite rods make them a versatile solution for a multitude of applications, ensuring superior performance and reliability in demanding industrial environments.One of the key features of the 1.85 Graphite Rods is their exceptional strength and stiffness. This makes them an ideal choice for applications where high mechanical performance is essential. Additionally, these rods exhibit excellent thermal conductivity and chemical resistance, making them suitable for use in extreme operating conditions. Whether it's in high-temperature furnaces, chemical processing equipment, or semiconductor manufacturing, these graphite rods deliver outstanding performance and longevity.Furthermore, the 1.85 Graphite Rods offer superior machining capabilities, allowing for the creation of complex and precise components. Their consistency and uniformity make them an excellent choice for applications that demand tight tolerances and intricate designs. With the ability to be machined into custom shapes and sizes, these graphite rods provide endless possibilities for design engineers and manufacturers.In addition to their exceptional mechanical and thermal properties, these graphite rods are also environmentally friendly. Graphite is a naturally occurring mineral with a low environmental impact, and its recyclability makes it a sustainable choice for companies aiming to reduce their carbon footprint. The production process at {Company Name} is designed to minimize waste and energy consumption, ensuring that the 1.85 Graphite Rods are not only high-performing but also environmentally responsible.The release of the 1.85 Graphite Rods marks a significant milestone for {Company Name}, solidifying their position as a leading supplier of advanced graphite products. With a strong focus on continuous improvement and customer collaboration, they are dedicated to providing innovative solutions that meet the evolving needs of modern industries. The introduction of these revolutionary graphite rods is a testament to their commitment to pushing the boundaries of materials technology and driving positive change in the industry.In conclusion, the 1.85 Graphite Rods are a game-changer for businesses in need of high-performance graphite products. With their exceptional mechanical properties, thermal conductivity, and environmental sustainability, these rods are set to transform the way industries approach their manufacturing and design challenges. Backed by the expertise and reliability of {Company Name}, these graphite rods are poised to make a significant impact in a wide range of applications, driving efficiency, reliability, and innovation for years to come.

Durable Graphite Trays: A Practical Solution for Serving and Display

Graphite trays are a crucial element in many industrial and manufacturing processes, and they play a vital role in the production, handling, and transportation of various materials. (Company Name) is a leading provider of high-quality graphite trays for a wide range of industries, offering exceptional performance and value to its customers.With over (number of years) years of experience in the industry, (Company Name) has established itself as a reliable and trusted supplier of graphite trays and other graphite products. The company prides itself on its commitment to quality, innovation, and customer satisfaction, and it continuously strives to exceed the expectations of its clients.Graphite trays are widely used in the metallurgy, chemical, and electronics industries, among others, and they are essential for processes such as powder metallurgy, sintering, and heat treatment. (Company Name) offers a comprehensive range of graphite trays in various sizes, shapes, and specifications to meet the diverse needs of its customers. The company's team of experts works closely with clients to understand their specific requirements and provide tailor-made solutions that meet their exact needs.One of the key advantages of graphite trays is their exceptional thermal stability and resistance to high temperatures, making them ideal for use in demanding industrial environments. (Company Name) utilizes the highest quality raw materials and advanced manufacturing techniques to ensure that its graphite trays deliver optimal performance and durability. This commitment to excellence has earned the company a solid reputation for reliability and consistency in the industry.In addition to its high-quality products, (Company Name) is also known for its exceptional customer service and support. The company's team of experienced professionals is dedicated to providing personalized attention and expert advice to help clients choose the right graphite trays for their specific applications. (Company Name) also offers comprehensive after-sales support, including maintenance and repair services, to ensure that its customers get the most out of their investment.As a customer-focused company, (Company Name) is continuously investing in research and development to further improve its products and stay at the forefront of the industry. The company is committed to staying ahead of the curve and meeting the evolving needs of its clients by embracing the latest technologies and innovative solutions. With a strong emphasis on quality and performance, (Company Name) is well-positioned to remain a leader in the graphite tray industry for years to come.In conclusion, graphite trays are essential components in many industrial processes, and (Company Name) is a leading provider of high-quality graphite trays for a wide range of applications. With a focus on quality, innovation, and customer satisfaction, the company is dedicated to delivering exceptional value to its clients and helping them achieve their goals. With its extensive experience, expertise, and commitment to excellence, (Company Name) is a trusted partner for businesses seeking reliable and high-performance graphite trays.