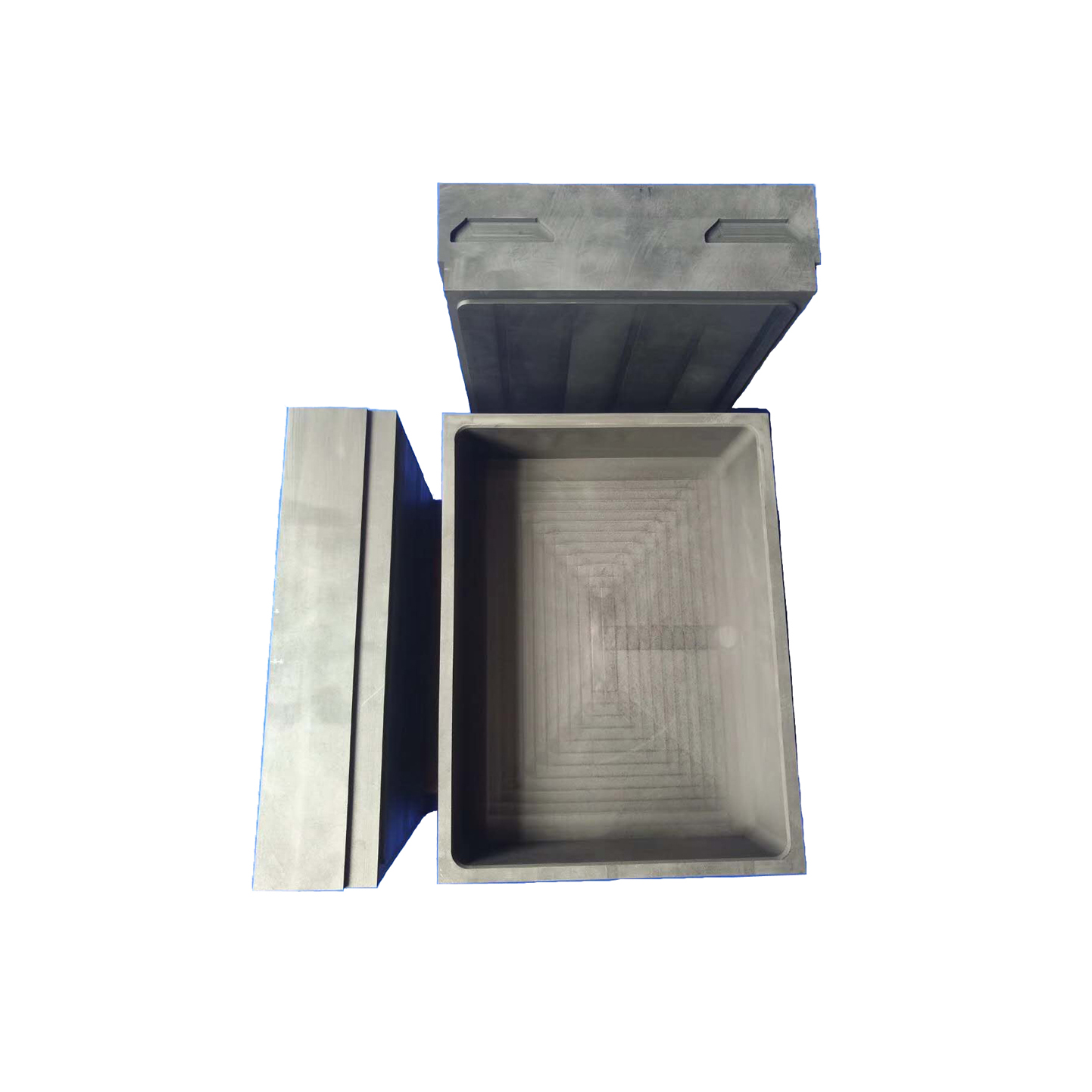

High-quality graphite crucibles for aluminum casting at competitive prices

By:Admin

Graphite crucibles are a crucial component in the aluminum casting process, and they play a vital role in ensuring the quality and integrity of the final product. The use of graphite crucibles in aluminum casting has become increasingly popular due to their superior thermal conductivity, high resistance to thermal shock, and ability to withstand extreme temperatures. As a result, they have become an essential tool for companies involved in the production of aluminum products.

One of the leading manufacturers of graphite crucibles for aluminum casting is {Company}. With a strong reputation in the industry, {Company} has been providing high-quality graphite crucibles for aluminum casting applications for many years. The company's commitment to excellence and innovation has led to the development of a wide range of graphite crucibles that are specifically designed to meet the unique requirements of aluminum casting processes.

{Company} understands the importance of using the right materials and equipment in the aluminum casting process, and their graphite crucibles have been engineered to deliver exceptional performance and reliability. They are manufactured using high-quality graphite materials that are carefully selected for their purity and consistency, ensuring that they are able to withstand the high temperatures and rigorous conditions of the aluminum casting process.

The use of graphite crucibles in aluminum casting offers several advantages, including excellent thermal stability, resistance to chemical corrosion, and minimal contamination of the molten aluminum. This results in a cleaner and more efficient casting process, ultimately leading to higher-quality aluminum products. Additionally, graphite crucibles are highly durable and have a long service life, making them a cost-effective solution for companies involved in aluminum casting.

{Company} offers a comprehensive range of graphite crucibles for aluminum casting, and their products are available in various sizes and configurations to suit different casting requirements. Whether it's for smelting, melting, or refining aluminum, {Company} has the expertise and capabilities to provide the right graphite crucible solution for any application.

The company's team of experienced engineers and technical experts are dedicated to providing customized solutions to meet the specific needs of their customers. They work closely with their clients to understand their aluminum casting processes and requirements, allowing them to develop tailored graphite crucible solutions that deliver superior performance and reliability.

{Company} is committed to delivering excellence in every aspect of their business, from product development and manufacturing to customer service and support. They prioritize quality and precision in their graphite crucible manufacturing process, ensuring that each product meets the highest standards of performance and reliability.

As a leading provider of graphite crucibles for aluminum casting, {Company} has built a strong reputation for delivering premium-quality products and exceptional customer service. They have established long-standing relationships with many aluminum casting companies, who rely on their graphite crucibles to achieve consistent and high-quality results in their casting operations.

In conclusion, the use of graphite crucibles is essential for the successful casting of aluminum products, and {Company} is a trusted supplier of high-quality graphite crucibles for this purpose. Their commitment to excellence, innovation, and customer satisfaction has positioned them as a leader in the industry, and they continue to set the standard for quality and performance in graphite crucible manufacturing. Companies involved in aluminum casting can rely on {Company} to provide the right graphite crucible solutions to help them achieve their production goals and maintain the highest standards of product quality.

Company News & Blog

Top-quality Isostatic Metal Casting Molds for High-performance EDM Graphite Marble Mold

High Performance EDM Graphite Marble Mold: A Boon for Isostatically Bearing Metal Casting MoldsMetal casting is one of the most widely used techniques employed for producing various metal products. It involves pouring molten metal into a mold and allowing it to solidify into the desired shape. However, this process is not as simple as it sounds. The metal has to be cast with precision to ensure that the final product meets the desired specifications. One way to ensure this is by using high-quality graphite molds. Graphite molds are extensively used in the metal casting industry due to their exceptional properties such as high thermal conductivity, excellent machinability, and low thermal expansion coefficient. The recent development of High-Performance EDM Graphite Marble Mold has revolutionized the industry.High-Performance EDM Graphite Marble Mold is one of the most advanced forms of graphite molds available today. This type of mold is made using high-quality isostatic graphite, which is a versatile and durable material. It is ideally suited for producing intricate and complex metal castings. The use of isostatic graphite ensures that the molds are free from any internal defects or cracks, which can affect the quality of the final product.The High-Performance EDM Graphite Marble Mold also employs the technique of Electrical Discharge Machining (EDM) to produce a precise and accurate mold. EDM is an advanced machining process in which electrical discharges are used to shape the material. It is an effective process for producing complex shapes with very high accuracy. The use of EDM in graphite mold production ensures that the molds are of the highest quality and precision.One of the key advantages of using High-Performance EDM Graphite Marble Mold is its exceptional thermal conductivity. Graphite has one of the highest thermal conductivity rates of any material. This allows the mold to quickly heat up and cool down, which is essential for producing metal castings with a high degree of accuracy. Moreover, the low thermal expansion coefficient of graphite enables the mold to maintain its shape and dimensions even at high temperatures.Isostatically Bearing Metal Casting Molds are particularly challenging to produce due to their complex geometry and tight tolerances. However, the use of High-Performance EDM Graphite Marble Mold has made this process much more manageable. The exceptional precision and accuracy of these molds make them ideal for producing isostatically bearing metal castings with a high degree of quality and consistency.The production of High-Performance EDM Graphite Marble Mold is a highly specialized process that requires expertise and experience. It involves the use of advanced equipment and techniques such as CAD modeling, CNC machining, and EDM. Therefore, it is essential to work with a reputable and experienced custom graphite molds manufacturer who can deliver high-quality molds tailored to your specific requirements.In conclusion, the development of High-Performance EDM Graphite Marble Mold has improved the quality and consistency of isostatically bearing metal casting molds. These molds offer exceptional precision, accuracy, and thermal conductivity, which are essential for producing high-quality metal castings. The use of isostatic graphite and EDM technology ensures that these molds are of the highest quality and can meet even the most demanding requirements of the industry. Therefore, the widespread adoption of High-Performance EDM Graphite Marble Mold is expected to significantly improve the efficiency and productivity of the metal casting industry.

Graphite Roller Price: Analyzing the Current Market Trends

Title: Increasing Demand for Graphite Rollers Drives Price Surge in the MarketIntroduction:Graphite rollers have gained significant traction in various industries due to their exceptional properties such as high thermal conductivity, excellent lubricity, and resistance to chemical corrosion. These characteristics make them ideal for applications in steel, aluminum, and non-ferrous metal industries, as well as in the paper, textile, and printing sectors. As a result, the demand for graphite rollers has been steadily increasing, causing a surge in prices across the market.Graphite Roller Price Surge Fueled by Growing Industrial Needs:The global market for graphite rollers has witnessed remarkable growth in recent years, primarily driven by expanding industrial activities worldwide. Industries such as steel, aluminum, and non-ferrous metals heavily rely on graphite rollers for critical processes, including continuous casting, heat treatment, and rolling. Moreover, the paper, textile, and printing industries use these rollers for various purposes such as drying, guiding, and printing applications.As these industries continue to witness growth and innovation, the demand for graphite rollers is surging at an unprecedented rate. This surge in demand has led to an upward trend in graphite roller prices. Manufacturers and suppliers are struggling to meet the growing demand, resulting in the need for increased production capacity and enhanced supply chain management.Global Market Dynamics Affecting Graphite Roller Prices:The global market dynamics play a crucial role in influencing the prices of graphite rollers. Fluctuating raw material costs, changes in international trade policies, and evolving technology have a direct impact on the pricing structure of graphite roller manufacturers. Moreover, the scarcity of high-quality graphite ore and the stringent regulations associated with the mining and extraction process further contribute to the escalating prices.In addition, the outbreak of the COVID-19 pandemic has disrupted the global supply chain and affected the availability of raw materials. This disruption, coupled with increased manufacturing costs due to safety measures, has created a ripple effect on graphite roller prices. Manufacturers have faced challenges in maintaining an uninterrupted supply of graphite rollers, leading to increased pricing pressure due to supply-demand imbalances.Efforts to Meet Rising Demand and Stabilize Prices:To cope with the increasing demand for graphite rollers and stabilize prices, manufacturers have focused on enhancing their production facilities and investing in research and development. Technological advancements have allowed manufacturers to improve the quality and durability of the rollers, thereby increasing operational efficiency for end-users.Furthermore, collaborations between graphite roller manufacturers and raw material suppliers have helped streamline the supply chain and ensure a continuous flow of raw materials. Novel sourcing strategies for graphite ore, including exploration of untapped mines and utilization of recycled graphite, are being explored to tackle the scarcity and high costs associated with raw material procurement.The drive towards sustainability is also influencing the production of graphite rollers. Manufacturers are adopting eco-friendly methods and investing in energy-efficient technologies to reduce the carbon footprint. This transition towards sustainable manufacturing practices aims to maintain a balance between environmental responsibility and meeting the ever-growing demands of various industries.Future Outlook:The increasing demand for graphite rollers is expected to persist in the coming years as industrial activities continue to expand. This sustained growth in market demand will drive research and development efforts further to enhance the properties and performance of graphite rollers, ultimately leading to a more competitive and innovative market.Moreover, as governments across the globe prioritize environmental regulations, the adoption of eco-friendly manufacturing practices in the graphite roller industry will become increasingly important. Manufacturers will focus on sustainable raw material sourcing, energy efficiency, and waste management, driving the industry towards a greener future.Conclusion:The surging demand for graphite rollers across numerous industries, including steel, aluminum, non-ferrous metals, paper, textile, and printing, is driving up prices in the market. Fluctuating raw material costs, changes in international trade policies, and disruptions caused by the COVID-19 pandemic have contributed to the current pricing dynamics. Manufacturers are actively investing in research and development, streamlining supply chains, and adopting sustainable manufacturing practices to meet the growing demand while regulating prices. As industrial activities continue to expand, the graphite roller market is set to witness further growth and innovation in the coming years.

Unique lid boat design from China - a game-changer in water sports industry

China Lid Boat Launches New Innovative Boat DesignChina Lid Boat, a leading manufacturer of marine vessels, has recently unveiled its latest innovation in boat design, the [simplified product name]. This new boat model combines cutting-edge technology with advanced materials to create a sleek and efficient watercraft that is sure to impress boating enthusiasts around the world.The [simplified product name] is the result of years of research and development by China Lid Boat's team of expert engineers and designers. The company's dedication to innovation and commitment to quality is evident in this new boat model, which promises to set a new standard for performance and functionality in the marine industry.One of the key features of the [simplified product name] is its unique lid design, which not only adds to the boat's aesthetic appeal but also serves a practical purpose. The lid provides easy access to the boat's storage compartments, making it simple for users to stow away their gear and belongings. Additionally, the lid also helps to streamline the boat's overall design, reducing wind resistance and improving fuel efficiency.In addition to its innovative lid design, the [simplified product name] also incorporates advanced materials such as carbon fiber and aluminum, which make the boat both lightweight and durable. This combination of materials allows for enhanced speed and maneuverability on the water, while also ensuring that the boat can withstand the rigors of marine environments.Furthermore, the [simplified product name] is equipped with state-of-the-art technology, including an advanced navigation system and integrated entertainment features. These technological enhancements not only add to the boat's overall appeal but also improve the safety and enjoyment of the boating experience for users.According to a spokesperson for China Lid Boat, the [simplified product name] represents a significant advancement in the company's product lineup. "We are thrilled to introduce the [simplified product name] to the market, as it embodies our commitment to innovation and excellence in boat design," the spokesperson stated. "We believe that this new model will exceed the expectations of our customers and set a new standard for performance and quality in the marine industry."The [simplified product name] is now available for purchase through China Lid Boat's global network of dealers and distributors. Boating enthusiasts who are interested in experiencing the cutting-edge design and advanced features of the [simplified product name] can contact their local dealer for more information and to schedule a test drive.For more information about China Lid Boat and its innovative marine vessels, visit the company's official website or contact their customer service team directly. With a strong commitment to quality, innovation, and customer satisfaction, China Lid Boat continues to lead the way in the marine industry, setting new standards for excellence in boat design and manufacturing.

Unlocking the Potential of Special Graphite: A Game Changer in Industrial Applications

Special Graphite: A Game-Changer in Advanced IndustriesIn the ever-evolving world of advanced materials, Special Graphite has emerged as a key player, revolutionizing various industries with its exceptional properties and unparalleled performance. With an extensive range of applications and a strong focus on innovation, Special Graphite has positioned itself as a game-changer in the world of advanced industries.Founded in [], Special Graphite has quickly gained prominence as a leading manufacturer and supplier of premium-quality graphite products. Committed to delivering excellence, the company has set the benchmark for superior quality, reliability, and customer satisfaction.The success of Special Graphite can be attributed to its state-of-the-art manufacturing facilities, where cutting-edge technology and advanced production techniques are employed. The company's world-class research and development team consistently strive to develop innovative solutions that meet the ever-evolving needs of its customers. By combining their expertise in materials science and engineering, they have been able to create a diverse portfolio of graphite products that cater to a wide range of industries.One of the key strengths of Special Graphite lies in its ability to customize its products according to customer requirements. Whether it's a complex-shaped component or a specific composition, the company's manufacturing capabilities allow for the production of tailor-made solutions. This flexibility has earned Special Graphite a reputation for being a reliable partner, capable of meeting the most demanding specifications.The versatility of Special Graphite is evident in its application across various industries. In the electronics industry, Special Graphite is widely used for the production of components such as crucibles, heating elements, and electrodes. Its excellent thermal stability, high electrical conductivity, and low thermal expansion make it an ideal choice for these critical applications.In the automotive sector, Special Graphite plays a pivotal role in the manufacturing of lithium-ion batteries, fuel cells, and brake systems. With the increasing demand for electric vehicles, the need for high-performance graphite materials has surged. Special Graphite's products meet these requirements, enabling the automotive industry to move towards a sustainable future.The aerospace industry also benefits greatly from Special Graphite's capabilities. Its lightweight yet robust nature, coupled with its resistance to high temperatures and corrosive environments, makes it an indispensable material for aircraft components, satellite systems, and rocket propulsion. The reliability and performance of Special Graphite have been crucial in ensuring the safety and efficiency of aerospace operations.Moreover, Special Graphite has made significant contributions to the metallurgical industry, where its products find applications in the production of steel, aluminum, and other metals. The unique properties of Special Graphite, such as its high thermal conductivity and low friction coefficient, enhance the efficiency of these processes, resulting in higher productivity and cost savings for manufacturers.In addition to its wide range of applications, Special Graphite places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively pursues eco-friendly practices throughout its operations. By focusing on energy efficiency, waste reduction, and responsible sourcing of raw materials, Special Graphite acts as a responsible corporate citizen, contributing towards a more sustainable future.In conclusion, Special Graphite has emerged as a major player in the advanced materials industry, earning a reputation for its exceptional products and commitment to innovation. With its focus on customization, versatility, and sustainability, the company has successfully revolutionized several industries, including electronics, automotive, aerospace, and metallurgy. As the demand for high-performance materials continues to rise, Special Graphite remains at the forefront, driving advancements and enabling progress in advanced industries worldwide.

Isostatic Graphite Industry: Growth, Usage, and Properties – Global & China Insights, 2018-2022

Isostatic graphite: The specialty graphite with exceptional propertiesIsostatic graphite, also known as molded graphite, is a type of high-end specialty graphite that has multiple exceptional properties. It differs from other types of graphite, as it is produced by isostatic pressing of graphite particles instead of the traditional extrusion or compression processes.The resulting material has a unique microstructure that gives it unmatched mechanical strength, high thermal conductivity, low thermal expansion coefficient, excellent electrical conductivity, and chemical inertness. Therefore, isostatic graphite has numerous applications across different industries, such as aerospace, semiconductor, nuclear, and metallurgy, among others.China is one of the leading producers and consumers of isostatic graphite, with a significant increase in demand over the last few years. The country has abundant graphite resources and advanced technologies to produce high-quality isostatic graphite, which is widely used for manufacturing graphite electrodes, crucibles, molds, and heating elements.China Isostatic Graphite Pot: The Innovative Solution for High-Temperature ApplicationsThe China Isostatic Graphite Pot is a new and innovative product that is made from high-quality isostatic graphite and has excellent performance in high-temperature applications. The pot is specially designed to withstand extreme temperatures and harsh chemical environments, making it the perfect solution for various industrial processes.One of the main advantages of the China Isostatic Graphite Pot is its ability to resist thermal shock and oxidation, which is critical in applications involving the melting and casting of metals and alloys. Its superior thermal stability also means that it can maintain its structural integrity and dimensional accuracy over a wide range of temperatures, even up to 3000°C.Moreover, the China Isostatic Graphite Pot has a low porosity and high density, which enables it to have excellent mechanical strength and wear resistance. It is also chemically inert, ensuring that it does not contaminate the molten metal or alloy during the casting process.Applications of China Isostatic Graphite PotThe China Isostatic Graphite Pot has numerous applications in different industries, including:1. Metallurgy: The pot is used for melting and casting various metals and alloys, such as steel, iron, copper, aluminum, and titanium, among others.2. Semiconductor: The pot is used for growing single crystals of silicon and other semiconductors, which are used in electronic devices.3. Aerospace: The pot is used for manufacturing rocket nozzles, heat shields, and other components that require high-temperature resistance.4. Chemical: The pot is used for carrying out chemical reactions that involve high temperatures and harsh chemicals.ConclusionIsostatic graphite is a unique and valuable material that has numerous applications across different industries. The China Isostatic Graphite Pot is a new and innovative solution that offers exceptional performance in high-temperature applications, especially in the metallurgy, semiconductor, aerospace, and chemical industries. With its superior thermal stability, mechanical strength, and chemical inertness, the China Isostatic Graphite Pot is an excellent investment for any industrial process that requires high-temperature resistance and dimensional accuracy.

How to Delete Graphite in Docker: Solution to Recreating Image and Container Issue

Unable to delete Graphite - Docker keeps recreating the image and containerGraphite is a monitoring platform that allows users to visualize and analyze data from various sources. Docker is a popular containerization platform that helps users create, deploy, and run applications in an isolated environment.Recently, users have reported issues with deleting Graphite in Docker. When attempting to delete the Graphite image and container, it keeps recreating itself. This has caused frustration for many users who are trying to free up space or remove unused containers.One user reported attempting to delete Graphite with the following steps:- docker stop graphite- docker rm graphite- docker rmi 740025f5293bHowever, even after executing these commands, the Graphite container and image keep reappearing. This has caused confusion and frustration for many users who are trying to clean up their Docker environment.The root cause of this issue is not yet clear. Some users speculate that it could be due to underlying dependencies or unresolved issues in the Graphite code. Others suggest that it could be an issue with Docker's caching and garbage collection mechanisms.Regardless of the cause, users are eager for a solution to this problem. Some have suggested simply avoiding Graphite altogether and using alternative monitoring platforms instead. However, for those who rely on Graphite for their monitoring needs, this is not a viable solution.In the meantime, users have suggested several workarounds for dealing with the issue. One suggestion is to disable automatic image and container creation in Docker. This can be done by adding the following line to the Docker daemon configuration file (usually located at /etc/docker/daemon.json): auto-create-images: falseAnother suggestion is to manually delete the Graphite container and image files from the Docker directory. This can be done by navigating to the Docker directory (usually located at /var/lib/docker) and deleting the relevant Graphite files.However, users should use caution when manually modifying Docker files, as this can potentially cause other issues with the Docker environment.Overall, the inability to delete Graphite in Docker is a frustrating and problematic issue for many users. While workarounds exist, a permanent solution to this issue is needed in order to ensure a smooth and seamless Docker experience for all users.

High-quality Graphite Crucibles Ideal for Melting Tin

Title: Graphite Crucible for Melting: A Reliable Choice for Industrial ApplicationsIntroduction:In various industrial sectors, the process of melting metals and other high-temperature applications plays a significant role. To ensure the success of these operations, the selection of high-quality equipment is essential. Graphite crucibles, popularly used for melting purposes, have gained immense popularity due to their exceptional properties and reliability. In this blog post, we will delve into the features, benefits, and applications of graphite crucibles for melting various materials in industrial settings.1. Understanding Graphite Crucibles:Graphite crucibles are specialized containers designed for holding and melting metals and other materials at extremely high temperatures. These crucibles are made from high-purity graphite, which exhibits remarkable thermal conductivity, corrosion resistance, and mechanical strength. The unique properties of graphite make it an ideal material for melting purposes.2. Key Features of Graphite Crucibles:2.1 High Thermal Conductivity:Graphite crucibles offer excellent heat transfer capabilities. Their high thermal conductivity ensures efficient and uniform melting of metals, eliminating the formation of hotspots, and providing consistent results.2.2 Corrosion Resistance:The chemical inertness of graphite makes crucibles highly resistant to corrosive agents. They can withstand aggressive molten materials, preventing contamination and maintaining the purity of the melted substance.2.3 Mechanical Strength:Graphite crucibles possess exceptional mechanical strength, allowing them to endure high temperatures and withstand thermal shock. This durability ensures longevity and enables multiple reuse cycles, making them a cost-effective choice.2.4 Excellent Insulation:Graphite crucibles exhibit excellent insulation properties, minimizing heat loss during melting operations. This feature increases energy efficiency and reduces operating costs.3. Benefits of Using Graphite Crucibles for Melting:3.1 Versatility:Graphite crucibles are compatible with a wide range of metals and materials. From precious metals like gold and silver to high-temperature alloys, graphite crucibles offer versatility for diverse melting requirements.3.2 Clean and Contamination-Free Melting:The non-reactive nature of graphite minimizes unwanted reactions, ensuring clean and pure melting processes. This aspect is crucial in industries like jewelry-making, where precise composition and flawless quality are imperative.3.3 Cost-Effective Solution:Graphite crucibles are highly durable and can withstand repeated use, making them a cost-effective solution in the long run. Additionally, their exceptional thermal conductivity reduces melting time and energy consumption, further contributing to cost savings.3.4 Easy Handling and Maintenance:Graphite crucibles are lightweight and easy to handle, simplifying the overall melting process and reducing the operational burden. Basic maintenance practices like periodic cleaning ensure the longevity of these crucibles.4. Applications of Graphite Crucibles:4.1 Metallurgy and Foundry:Graphite crucibles find extensive usage in the metallurgical and foundry industries for melting and casting various metals such as iron, steel, aluminum, and copper. Their thermal resistance and durability make them an ideal choice in these demanding operations.4.2 Jewelry-Making:The jewelry industry relies heavily on graphite crucibles for melting precious metals, enabling the creation of intricate and high-quality jewelry designs. The purity maintained during melting ensures flawless end products.4.3 Laboratory Applications:Graphite crucibles are widely employed in laboratory settings for experiments requiring high temperatures and controlled melting processes. Their reliability and consistency make them a trusted choice for scientific research and analysis.Conclusion:Graphite crucibles are a reliable and efficient solution for melting operations in diverse industries. Their exceptional properties, including high thermal conductivity, corrosion resistance, and mechanical strength, make them ideal for applications ranging from foundries to jewelry-making and laboratory experiments. With their cost-effectiveness and versatility, graphite crucibles continue to be the go-to choice for achieving efficient and contamination-free melting processes.

High-Quality Graphite Paper: A Key Component for Various Applications

Graphite Paper Revolutionizing the Manufacturing IndustryIn recent years, there has been an increasing demand for more efficient and sustainable manufacturing processes. Companies are continually seeking innovative solutions to enhance their production methods while also reducing their environmental impact. One prominent development that has gained significant attention is the emergence of Graphite Paper, a revolutionary material that is transforming the manufacturing industry.Graphite Paper () is highly regarded for its unique properties, making it an ideal choice for various manufacturing applications. It is a thin, flexible material that is composed of high-quality graphite flakes. The exceptional conductivity and thermal stability of graphite make it an unparalleled option for use in a wide range of industries, including electronics, automotive, aerospace, and more.One of the primary advantages of Graphite Paper is its ability to efficiently dissipate heat. This property is particularly valuable in electronic devices and battery systems, where thermal management is essential for preventing overheating and ensuring optimal performance. The use of Graphite Paper as a thermal interface material has significantly improved the heat dissipation capabilities of electronic components, leading to enhanced reliability and longevity.Furthermore, Graphite Paper has proven to be an effective solution for improving the structural integrity of composite materials. By integrating Graphite Paper into composite structures, manufacturers are able to enhance their mechanical properties, including tensile strength and flexural stiffness. This has led to the development of lighter, stronger, and more durable materials for various applications, such as aircraft components and sporting goods.In the automotive industry, Graphite Paper has demonstrated its potential in advancing the performance of electric vehicles (EVs). The material's high conductivity and lightweight nature make it an ideal candidate for use in battery packs and thermal management systems, contributing to the overall efficiency and safety of EVs. Additionally, Graphite Paper has been instrumental in improving the energy density and lifespan of lithium-ion batteries, addressing critical challenges in the advancement of sustainable transportation.The aerospace sector has also welcomed the introduction of Graphite Paper as a groundbreaking solution for advancing aircraft technology. With its exceptional thermal conductivity and fire-resistant properties, Graphite Paper has been integrated into aircraft components to enhance their thermal performance and fire safety. This has enabled the development of more resilient and lightweight aircraft structures, contributing to improved fuel efficiency and reduced environmental impact.Despite its remarkable capabilities, the adoption of Graphite Paper in manufacturing has faced certain challenges, including scalability and cost-effectiveness. However, ongoing research and development efforts are focused on overcoming these obstacles and further expanding the applications of Graphite Paper across diverse industries.The production and supply of Graphite Paper are being driven by leading companies at the forefront of advanced materials innovation. These companies have dedicated significant resources to the refinement of Graphite Paper manufacturing processes, aiming to enhance its properties and ensure consistent quality. Moreover, they have actively collaborated with manufacturers to implement Graphite Paper into their products, providing comprehensive support and expertise throughout the integration process.Furthermore, the commitment to sustainability and eco-friendly practices is ingrained in the production of Graphite Paper, aligning with the growing emphasis on environmental responsibility within the manufacturing industry. By leveraging renewable resources and minimizing waste, Graphite Paper manufacturers are contributing to a more sustainable and greener future for the manufacturing sector.In conclusion, the advent of Graphite Paper has heralded a new era of possibilities for the manufacturing industry. Its remarkable properties and versatile applications have positioned it as a game-changing material, driving advancements in thermal management, structural enhancement, and energy storage solutions. As ongoing research and development continue to elevate the capabilities of Graphite Paper, its potential to revolutionize manufacturing processes and products is undoubtedly promising. Moreover, its contribution to advancing sustainability and environmental stewardship underscores its significance in shaping the future of manufacturing.

High-quality Graphite Die for Industrial Use

Graphite Die, a highly specialized component used in various industrial processes, is an essential tool for precision manufacturing in diverse industries such as automotive, aerospace, and electronics. The Graphite Die is a critical element in the production of complex parts and components, providing the necessary precision and durability to meet the high standards of modern manufacturing.Since its establishment, {Company Name} has been at the forefront of the graphite die manufacturing industry, providing high-quality products and services to its clients worldwide. With a strong focus on innovation and technology, the company has successfully developed advanced production techniques and state-of-the-art materials to meet the evolving demands of its customers.The Graphite Die is an integral part of the manufacturing process, used in a wide range of applications such as die casting, metal extrusion, and glass molding. With its unique properties, including high temperature resistance, low coefficient of thermal expansion, and excellent machinability, graphite has become the material of choice for manufacturing precision dies.{Company Name} has been committed to providing its clients with the highest quality graphite dies, utilizing advanced manufacturing processes and stringent quality control measures to ensure the reliability and performance of its products. The company's team of skilled engineers and technicians work closely with its clients to understand their specific needs and requirements, offering customized solutions that meet the most demanding standards of precision and quality.The use of graphite dies in the manufacturing process offers numerous advantages, including improved product quality, reduced production time, and enhanced cost-efficiency. With its unique combination of properties, graphite provides the necessary strength and durability to withstand the high pressures and temperatures involved in industrial processes, resulting in superior performance and longer tool life.In addition to its core products, {Company Name} also offers a range of value-added services to its clients, including die design and engineering, prototyping, and technical support. This comprehensive approach enables the company to provide a complete solution to its clients, from the initial design phase to the final production stage, ensuring the highest level of quality and accuracy throughout the entire process.As a leading supplier of graphite dies, {Company Name} has established a strong reputation for its commitment to quality, innovation, and customer satisfaction. The company's continued investment in research and development, along with its dedication to excellence, has positioned it as a trusted partner for a wide range of industries, from automotive and aerospace to electronics and consumer goods.With the increasing demand for high-precision manufacturing solutions, the role of graphite dies in modern industry continues to be pivotal. {Company Name} remains dedicated to meeting the evolving needs of its clients, delivering reliable and high-performance graphite dies that contribute to the success of their manufacturing operations.In conclusion, the Graphite Die plays an essential role in the production of precision parts and components, serving as a critical tool in various industrial processes. {Company Name}'s commitment to excellence and innovation has positioned it as a leading supplier of graphite dies, offering high-quality products and services to meet the diverse needs of its clients worldwide. With its advanced manufacturing techniques and comprehensive range of value-added services, the company continues to drive the advancement of the graphite die industry, providing innovative solutions that contribute to the success of modern manufacturing.

High-Quality Edm Mold for Graphite: What You Need to Know

Graphite EDM Mold: A Cutting-Edge Solution for Precision ManufacturingIn today’s fast-paced manufacturing industry, precision and efficiency are paramount. Companies are constantly seeking innovative solutions to stay ahead of the competition, and one such solution that has been garnering attention is the Graphite EDM Mold. This cutting-edge technology is revolutionizing the way manufacturers produce intricate and complex parts, and it is quickly becoming a staple in the arsenal of high-tech manufacturing companies.The Graphite EDM Mold is a precision tool used in electrical discharge machining (EDM) processes, which involves using electrical discharges to shape and produce intricate parts from hard metals and materials. The mold is made from high-quality graphite, which is an ideal material for EDM applications due to its high thermal conductivity and ability to withstand high temperatures.One company that has been at the forefront of developing and producing Graphite EDM Mold is {Company Name}. With over 20 years of experience in the manufacturing industry, {Company Name} has established itself as a leading provider of advanced tooling solutions for a wide range of industries, including aerospace, automotive, medical, and more. Their commitment to innovation and quality has led to the development of the Graphite EDM Mold, which has become a game-changer for manufacturers looking to produce intricate and high-precision parts.The Graphite EDM Mold offers several key advantages over traditional tooling solutions. Its high thermal conductivity allows for efficient heat dissipation during the EDM process, which results in improved surface finish and dimensional accuracy of the machined parts. Additionally, the inherent strength and stability of graphite make the mold highly durable and resistant to wear, resulting in longer tool life and reduced production downtime for tool changes.Furthermore, the Graphite EDM Mold is highly customizable and can be tailored to meet the specific needs of different applications and industries. {Company Name} offers a range of customization options, including varying graphite grades, electrode geometries, and surface finishes, to ensure that their customers can achieve the desired machining results for their unique parts.The use of Graphite EDM Mold has brought about a paradigm shift in the way manufacturers approach the production of complex and precision parts. With its ability to achieve tight tolerances and intricate geometries, the mold has opened up new possibilities for designing and manufacturing parts that were previously deemed too challenging or costly to produce.The aerospace industry, in particular, has embraced the Graphite EDM Mold as a critical tool for producing components with stringent tolerances and complex geometries. From turbine blades to fuel nozzles, manufacturers in the aerospace sector have turned to this advanced tooling solution to achieve the level of precision and quality required for their critical components.In the medical industry, the Graphite EDM Mold has also become instrumental in the production of intricate surgical instruments and implants. The mold’s ability to produce intricate and complex shapes with high precision has enabled manufacturers to push the boundaries of what is possible in terms of design and functionality for medical devices.Looking ahead, the future of Graphite EDM Mold looks promising, with continued advancements in materials and manufacturing techniques. As the demand for high-precision components continues to grow across various industries, the role of the Graphite EDM Mold is expected to expand even further, driving innovation and pushing the boundaries of what can be achieved in precision manufacturing.In conclusion, the Graphite EDM Mold has emerged as a cutting-edge solution for precision manufacturing, offering unparalleled capabilities to produce intricate and complex parts with high precision and efficiency. With {Company Name} at the helm of its development and production, the mold is poised to revolutionize the manufacturing industry and pave the way for new possibilities in design and production. As the demand for high-precision components continues to grow, the Graphite EDM Mold is set to play an increasingly pivotal role in shaping the future of manufacturing.