How to Use an Ignot Mold for Graphite

By:Admin

One company that has been at the forefront of providing top-notch graphite ignot molds is {company introduction}. With over 20 years of experience in the industry, {company name} has established itself as a leading manufacturer and supplier of graphite products, including ignot molds, crucibles, and other graphite components. Their commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation in the market.

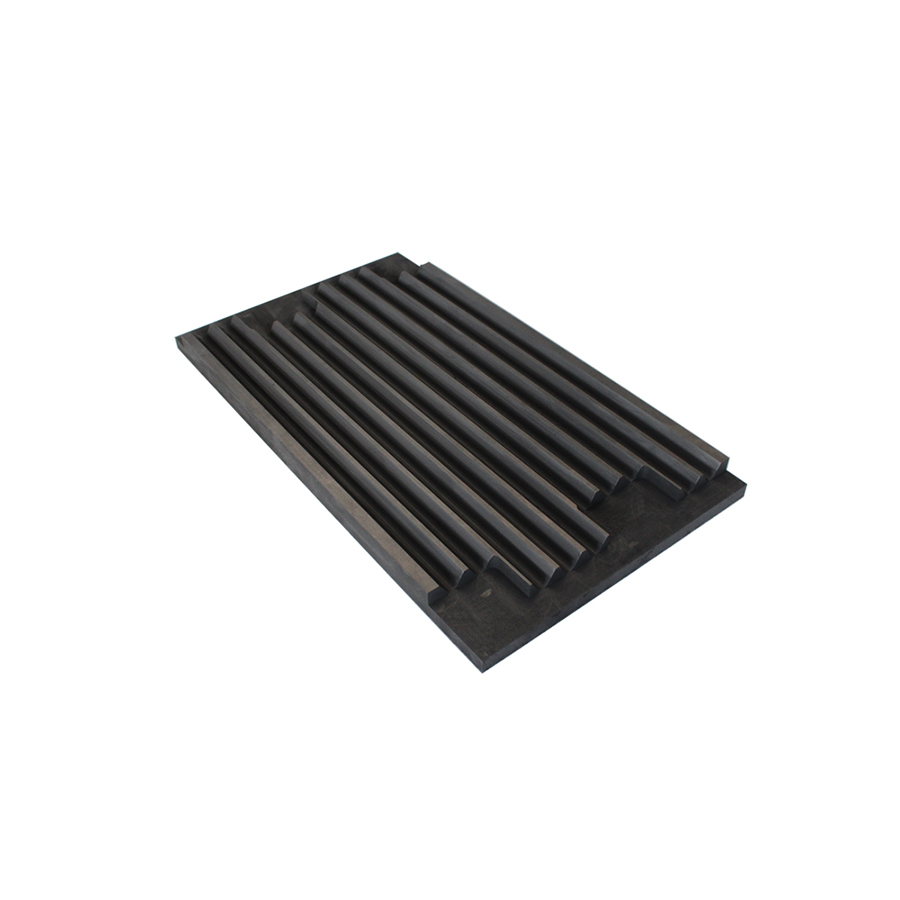

The graphite ignot molds produced by {company name} are made from high-quality graphite materials that offer excellent thermal stability, resistance to thermal shock, and superior strength. These properties make their ignot molds ideal for withstanding the intense heat and pressure involved in the casting process, ensuring the production of flawless ingots every time.

Furthermore, {company name} offers a wide range of graphite ignot molds with different sizes and specifications to cater to the diverse needs of their customers. Whether it is for small-scale operations or large industrial applications, the company can provide customized solutions to meet specific requirements.

In addition to their high-quality products, {company name} also takes pride in their commitment to innovation and continuous improvement. They invest in research and development to explore advanced technologies and techniques that can further enhance the performance and efficiency of their graphite ignot molds. This dedication to innovation has allowed them to stay ahead of the curve and anticipate the evolving needs of the industry.

One of the key factors that set {company name} apart from their competitors is their unwavering focus on customer satisfaction. They work closely with their clients to understand their unique challenges and requirements, allowing them to deliver tailored solutions that exceed expectations. By providing exceptional technical support and reliable after-sales service, {company name} has built enduring relationships with their customers, earning their trust and loyalty.

The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every graphite ignot mold that leaves their premises adheres to the highest standards of quality and performance. This commitment to excellence has enabled {company name} to gain the trust of customers not only in the domestic market but also in various international markets.

As the demand for high-quality ingots continues to grow across different industries, {company name} remains dedicated to meeting this demand by providing reliable and high-performance graphite ignot molds. With their track record of excellence, commitment to innovation, and customer-centric approach, they are well-positioned to continue leading the market and setting new benchmarks in the industry.

In conclusion, the role of graphite ignot molds in the production of quality ingots cannot be overstated, and {company name} has emerged as a trusted partner for businesses looking to source top-notch graphite ignot molds. With their focus on quality, innovation, and customer satisfaction, the company is poised to continue its success and make valuable contributions to the industry for years to come.

Company News & Blog

Discover the Latest Innovations in Sintering Graphite Crucibles from China

China Sintering Graphite Crucible Boosting Industrial Growth and Efficiency(Company Introduction)With over two decades of experience in the graphite industry, our company has become a leading manufacturer and supplier of high-quality graphite products in China. We specialize in producing sintering graphite crucibles, which have gained widespread recognition for their exceptional performance and durability. Our commitment to excellence and innovation has propelled us to the forefront of the industry, enabling us to cater to a diverse range of industrial needs.(Graphite Crucible Market Overview)The global graphite crucible market has been witnessing significant growth in recent years, driven by the expanding industrial sector and the increased demand for efficient and reliable crucibles in various manufacturing processes. Graphite crucibles play a vital role in industries such as foundries, metallurgy, chemicals, and jewelry making, where they are used for melting, casting, and holding molten metals and alloys.(Features and Benefits of China Sintering Graphite Crucibles)Our sintering graphite crucibles offer a wide range of features and benefits that distinguish them from other crucible options available in the market. The sintering process enhances the structure and properties of the graphite, making it denser and more resistant to thermal shock. This ensures uniform heat distribution, improved thermal conductivity, and higher mechanical strength, resulting in superior performance and longer crucible lifespans.Additionally, our graphite crucibles exhibit excellent corrosion resistance, enabling them to withstand the corrosive effects of various molten metals and alloys. Their non-wetting property prevents metal contamination, ensuring the purity of the final product. Moreover, the high thermal stability and low coefficient of thermal expansion of our crucibles make them highly reliable even under extreme temperature conditions.(Application and End-User Industries)China sintering graphite crucibles find extensive application in numerous industries:1. Foundries: Graphite crucibles are commonly used in foundries for melting and casting processes. Their superior thermal properties and resistance to thermal shock make them ideal for handling high-temperature alloys.2. Metallurgy: Crucibles are essential in metallurgical laboratories for conducting various analytical tests and experiments. The excellent thermal conductivity of graphite ensures accurate and precise results.3. Chemical Industry: The chemical industry utilizes graphite crucibles for various chemical reactions, including melting and evaporation. The crucibles' resistance to corrosive chemicals and high temperatures ensures the safety and efficiency of these processes.4. Jewelry Making: Graphite crucibles are widely used in jewelry making for casting precious metals such as gold, silver, and platinum. Their excellent thermal properties and smooth surface finish allow for precise casting and minimal product loss.(Advantages of Choosing China Sintering Graphite Crucibles)By selecting China sintering graphite crucibles, industrial customers can enjoy several advantages:1. Competitive Pricing: Our graphite crucibles are competitively priced without compromising on quality. This allows businesses to lower their production costs and improve overall profitability.2. ISO Certification: Our company holds ISO 9001:2015 certification, which guarantees that our crucibles meet the highest international quality standards. This assures customers of consistent product performance and reliability.3. Customization Options: We understand that different industries have unique requirements. Therefore, we offer customization options to tailor our graphite crucibles to specific customer needs, be it size, shape, or other specifications.4. Excellent Customer Service: Our dedicated customer service team ensures prompt response and efficient handling of inquiries, orders, and after-sales services. We strive to cultivate long-term partnerships with our clients by providing exceptional service and support.(Future Outlook)Looking ahead, the demand for graphite crucibles is expected to continue growing, driven by ongoing industrialization and advancements in manufacturing technologies. As a leading manufacturer, we are committed to meeting this growing demand by further enhancing our production capabilities and expanding our product offerings. We will continue to invest in research and development, leveraging the latest innovations to provide even more advanced and efficient graphite crucibles to our customers.In conclusion, China sintering graphite crucibles have emerged as a reliable and efficient solution for various industries' melting, casting, and holding needs. With their exceptional performance, durability, and competitive pricing, these crucibles have become indispensable in improving industrial growth and efficiency. As our company continues to innovate and expand, we look forward to serving both domestic and international markets with the highest quality graphite crucibles.

Affordable Graphite Vane Plates for Vacuum Pumps - High-Quality Manufacturers & Suppliers in China

Graphite Plate Price: Cost-Effective Solutions for High-Performance Vacuum PumpsWhen it comes to vacuum pumps, every component plays a crucial role in ensuring optimal performance and longevity. One such component is the graphite vane plate, which is used in rotary vane vacuum pumps to create a seal and generate suction.If you're in the market for high-quality graphite vane plates at a reasonable price, look no further than China - a leading manufacturer of these components. In this blog, we'll explore the benefits of using graphite vane plates and how to find the best prices.Why Choose Graphite Vane Plates for Vacuum Pumps?Graphite is an excellent material for vacuum pump vane plates due to its unique properties. Unlike metals, graphite is self-lubricating, meaning it can withstand high temperatures and operate without additional oil or lubricants. This makes it ideal for use in vacuum pumps that require high-speed, continuous operation.Graphite vane plates are also highly resistant to wear and tear, chemical corrosion, and oxidation. They offer excellent dimensional stability and can withstand extreme pressure differentials, making them suitable for use in harsh industrial environments.Another notable advantage of using graphite vane plates is their low friction and superior vibration damping properties. This helps reduce noise and vibration levels, which is crucial for applications that require low noise emissions like medical equipment, laboratories, and semiconductor manufacturing.Finding the Best Graphite Plate PriceIf you're looking to source high-quality graphite vane plates at a competitive price, consider partnering with a reputable manufacturer in China. China has emerged as a global leader in the production of graphite components, offering a wide range of products with different specifications, sizes, and shapes to suit various applications.When selecting a supplier, it's essential to consider several factors, such as quality, delivery time, packaging, and customer service. Look for a company that uses advanced production facilities and strict quality control measures to ensure consistent quality.Also, consider the supplier's pricing policy, payment methods, and shipping options. Some suppliers may offer discounts for bulk orders or provide free samples for testing purposes. It's also essential to ensure that the supplier can provide timely and secure shipping to your destination.ConclusionIn summary, graphite vane plates are an essential component of rotary vane vacuum pumps, offering superior performance, durability, and reliability in harsh industrial environments. Investing in high-quality graphite vane plates can help you reduce maintenance costs, increase productivity, and improve operational efficiency.If you're looking for the best graphite plate price, turn to China - a reliable and cost-effective source of high-quality graphite components. Selecting the right supplier can help you achieve your production goals and stay competitive in the global market.

Plastic and Glass Stirring Rods for Laboratory Use

Graphite Stirring Rods: The Key to Efficient and Effective Laboratory WorkLaboratory work is an essential aspect of scientific research and experimentation, and it involves a wide range of tasks and activities. One of the most important activities carried out in the laboratory is mixing and stirring different substances to create solutions, suspensions, emulsions, and other mixtures. For this purpose, laboratory technicians and researchers use various types of stirring rods, including plastic, glass, and graphite rods.In recent years, graphite stirring rods have become increasingly popular among laboratory professionals due to their unique properties and advantages. Graphite, a form of carbon, is an excellent conductor of heat and electricity, making it ideal for use in laboratory equipment. Graphite stirring rods are lightweight, durable, and highly resistant to corrosion, chemicals, and abrasion. They are also non-reactive and do not contaminate the substances being mixed, ensuring accurate and consistent results.The use of graphite stirring rods in laboratory work offers several benefits, including:1. Greater efficiency: Graphite stirring rods are highly efficient in mixing and stirring liquids, powders, and other substances. They have a smooth surface that reduces friction, allowing for faster and more thorough mixing.2. Improved accuracy: Graphite stirring rods do not impart any flavor, odor, or color to the solutions, ensuring accurate and reliable results. They are also easy to clean and sterilize, reducing the risk of contamination.3. Cost-effectiveness: Graphite stirring rods are more cost-effective than other types of stirring rods, as they have a longer lifespan and do not require frequent replacement.4. Versatility: Graphite stirring rods are versatile and can be used in a wide range of laboratory applications, from chemical reactions and sample preparation to food and beverage testing.When selecting a graphite stirring rod, it is important to consider the diameter, length, and shape of the rod. The diameter of the rod should be appropriate for the volume of the solution being mixed, while the length of the rod should be long enough to reach the bottom of the container. The shape of the rod can vary depending on the application, with common shapes including cylindrical, rectangular, and conical.In addition to graphite stirring rods, laboratory professionals may also use other types of stirring rods, such as plastic and glass rods. While these rods may be suitable for some applications, they lack the unique properties and advantages of graphite rods. Plastic rods are lightweight and disposable but may not be suitable for use with strong chemicals or high temperatures. Glass rods, on the other hand, are highly resistant to chemicals and high temperatures but may break easily and require careful handling.In conclusion, graphite stirring rods are an excellent choice for laboratory work due to their unique properties and advantages. They offer greater efficiency, improved accuracy, cost-effectiveness, and versatility, making them ideal for a wide range of laboratory applications. When selecting a graphite stirring rod, it is important to consider the diameter, length, and shape of the rod to ensure optimal performance and results. By choosing the right stirring rod for their application, laboratory professionals can ensure accurate, reliable, and efficient results in their work.

Low Temperature Microwave Drying for Ceramic Glaze Powder: Advanced Drying Technology

Ceramic Glaze Powder Microwave Drying Machine: Revolutionizing the IndustryMicrowave drying technology has become a hot topic in industrial circles, especially in the manufacturing of ceramics, as this method stands to modernize the process and revolutionize the industry. One of the latest innovations is the ceramic glaze powder microwave drying machine that has gained popularity among industry players. This equipment can dry ceramic glaze powders, efficiently, faster and more uniformly than other drying technologies.In recent years, the ceramic industry has experienced significant improvements in its production technology, resulting in the development of better and more efficient equipment. The traditional drying method, using electric ovens, gas ovens or tunnel kilns, is now outdated and inadequate when it comes to meeting the demand for faster and more efficient production processes. In contrast, the ceramic glaze powder microwave drying machine utilizes electromagnetic energy to generate heat, which uniformly and rapidly dries the glaze powder. Moreover, this technology significantly reduces production costs, as it requires less space, energy and time. Additionally, it minimizes waste, as it has zero emissions and releases no harmful gases into the environment, creating a safer working environment for workers. The ceramic industry has turned to low temperature microwave drying {need remove brand name} technology combined with vacuum furnace sintering graphite container for ceramics, resulting in significant advancements in the manufacturing process. Low-temperature microwave drying utilizes low-frequency energy to generate heat, which is absorbed by the ceramics' surface. The process occurs in a vacuum environment, where moisture evaporates under low pressure, eliminating vapor's need to travel through the air. This innovative method translates to a faster drying time while ensuring high-quality products.The vacuum furnace sintering graphite container works hand-in-hand with the low-temperature microwave drying technology, making it possible to achieve even faster production times. The container is designed to withstand the high temperatures required to sinter ceramics as they dry. The graphite container guarantees safe and high-quality production, offering a more environmentally friendly and cost-effective alternative to traditional methods.The microwave drying sterilization equipment is another technology that is making waves in the industry. This special equipment uses high-frequency electromagnetic waves to sterilize and dry products simultaneously. The process eliminates the need for hazardous chemicals, minimizes production costs, enhances food safety and nutritional quality while reducing energy requirements.Microwave sintering equipment is yet another innovation that responds to the industry's need for more efficient and environmentally friendly production processes. This equipment uses electromagnetic waves to create heat, which entirely sinter ceramics at high temperatures. The process is energy-efficient, helps reduce carbon emissions, and ensures high quality and fast production.In conclusion, microwave drying technology offers a faster, more efficient, cost-effective, and eco-friendly solution that will revolutionize the ceramic industry. Manufacturers must incorporate these new technologies to stay up to date with the industry's advancements while reducing their carbon footprint and increasing profitability.

Shop Stylish and Affordable Roller Shades in Graphite - Enjoy Free Shipping | Window Treatments Department

Shades, Window Treatments, Home Decor, Light Control, Energy Efficiency, Privacy, Convenience, Style and DurabilityAt the mention of window treatments, the first thing that comes to mind is curtains. But, did you know that roller shades are just as effective in enhancing your home decor and serving a host of functional purposes? In this blog, we'll delve deeper into the world of roller shades, and highlight the benefits of choosing Graphite Roller Shades for your home. Firstly, let's talk about why roller shades are an excellent choice for your window treatments. Roller shades are known for their simplicity and functionality. They are designed to roll up and down smoothly, making them easy to operate. Unlike curtains, they take up less space, which is an advantage if you have limited space in your room. Moreover, they offer effective light control, energy efficiency, privacy, and convenience. When it comes to selecting roller shades, there are several options available in the market. However, not all roller shades are created equal. If you're looking for a roller shade that offers style and durability, Graphite Roller Shades from (need to remove brand name) are worth considering. Graphite Roller Shades are a popular choice for homeowners and interior designers alike, thanks to their elegant and sophisticated look. They come in a soft and soothing grey color that adds depth and dimension to any room. The graphite hue is versatile and complements a wide range of color schemes, making it easy to incorporate into your home's decor. Beyond style, Graphite Roller Shades are durable and built to last. They are made of high-quality materials that can withstand wear and tear, ensuring that they look great and function optimally for years to come. The Home Depot provides free shipping for Graphite Roller Shades or Buy Online Pick Up in Store today in the Window Treatments Department.Graphite Roller Shades are also efficient in controlling light and protecting your privacy. The shade's fabric is designed to filter out the sun's harsh rays, reducing glare and preventing fading of your furnishings. Additionally, they come in different opacity levels, allowing you to choose the level of privacy you want without impeding the natural lighting of your room. Another benefit of Graphite Roller Shades is energy efficiency. They help to regulate the temperature of your room by blocking out the sun's heat during summer and insulating your home, keeping it warm during winter. This results in lowered energy bills and a more comfortable living environment. In conclusion, roller shades are a sophisticated and practical alternative to traditional curtains. Graphite Roller Shades, in particular, offer style, durability, light control, energy efficiency, privacy, and convenience. They are a versatile option for any room in the house and are an excellent addition to your home decor. So, why not elevate your home's style and functionality by choosing Graphite Roller Shades today?

Top Graphite Products Supplier: Delivering High-Quality Industrial Solutions

Graphite Products Supplier Expands Offerings to Meet Growing Market Demand[City, Date] - Graphite Products Supplier, a leading provider of high-quality graphite products, has announced a significant expansion of its product offerings to meet the growing market demand. With a strong commitment to excellence and a focus on delivering superior products, the company aims to cater to a wide range of industries that rely on graphite components.Graphite is a versatile material known for its unique properties, making it highly valuable in various industries such as aerospace, automotive, electronics, and energy. Its excellent thermal and electrical conductivity, along with its high strength and low weight, makes it an ideal choice for manufacturing various essential components.With a proven track record of delivering exceptional graphite solutions, Graphite Product Supplier has established itself as a reliable partner to companies across different sectors. The company provides a wide range of graphite products, including graphite rods, tubes, plates, and machined parts, to meet diverse industrial needs.The recent expansion of the company's product offerings is driven by the growing market demand for graphite components and the need to cater to various custom requirements. By adding new products to its portfolio, Graphite Products Supplier aims to better serve its existing customers while also attracting new clients seeking high-quality graphite solutions.The company's extensive research and development efforts have enabled them to develop advanced graphite products that are at the forefront of technological innovation. With state-of-the-art manufacturing facilities and a team of experienced professionals, Graphite Products Supplier ensures that its products adhere to the highest quality standards.One of the key highlights of the expanded product line is the introduction of enhanced graphite electrodes. These electrodes are widely utilized in electric arc furnaces for steel production and are critical in maintaining high efficiency and quality in the steelmaking process. The advanced properties of these graphite electrodes, such as high thermal conductivity and low electrical resistance, contribute to improved productivity and cost-effectiveness for steel manufacturers.Furthermore, the company is also introducing high-performance graphite crucibles, which are essential in various industrial applications such as metal casting, chemical analysis, and melting processes. With superior thermal stability and resistance to chemical corrosion, these crucibles ensure efficient and reliable operations in demanding environments.Graphite Products Supplier remains committed to sustainable practices, both in terms of product development and manufacturing processes. The company emphasizes using eco-friendly materials and implementing energy-efficient techniques to minimize its environmental impact. By incorporating sustainable practices throughout its operations, Graphite Products Supplier strives to create a positive and responsible impact on the planet.To support this expansion and meet the increased demand for its products, Graphite Products Supplier plans to further invest in research and development capabilities as well as production capacity. These initiatives will contribute to driving innovation, improving product performance, and maintaining a competitive edge in the market.With its expanded product offerings and a continued focus on customer satisfaction, Graphite Products Supplier is well-positioned to meet the evolving needs of various industries that rely on high-quality graphite components. The company's commitment to excellence, sustainability, and technological advancement ensures that it remains a trusted partner for companies seeking reliable graphite solutions.About Graphite Products Supplier:Graphite Products Supplier is a leading provider of high-quality graphite products, serving a wide range of industries globally. With a strong commitment to excellence and sustainability, the company delivers cutting-edge graphite components that meet the unique needs of its clients. Through continuous research and development efforts, Graphite Products Supplier remains at the forefront of technological innovation and aims to provide superior solutions to its customers.Contact:[Company Name][Contact Person][Address][Phone][Email][Website]

Next-Generation Semiconductor Material Breaking Barriers in Electronics Industry

The rise of electric vehicles has put the spotlight on new technologies that can provide the power and efficiency required for this growing market. One of the key technologies that enable electric vehicles to travel long distances is power electronics. This technology is what allows electricity to be stored and transported in a vehicle's battery pack and converted into high-voltage power that can drive the motor. Silicon Carbide (SiC) is emerging as a key player in this space, thanks to its capabilities to deliver high-efficiency, high-reliability power electronics.SiC has been around for a long time as a semiconductor material, but only recently has it gained traction in the power electronics industry. This is because it offers many advantages over traditional semiconductor materials like silicon, which is currently in widespread use. One of the key advantages of SiC is that it can handle higher voltages than silicon, which makes it ideal for use in high-power devices like electric vehicle inverters.Another advantage of SiC is its ability to operate at higher temperatures than silicon, which means it can handle more power without failing. This is particularly important in electric vehicles, where the power electronics need to operate at maximum efficiency for extended periods. SiC's high thermal conductivity also helps to keep the temperature down, reducing the need for bulky cooling systems.SiC offers increased efficiency, with the ability to reduce power losses and extend the driving range of electric vehicles. This makes SiC an important technology for providing the power and performance needed for the next generation of electric vehicles. The market is responding to this demand, with SiC-related businesses intensifying R&D efforts on this emerging technology.One company that has been at the forefront of SiC development is {company}. The company has invested heavily in SiC technology, and is now one of the leading players in the SiC market. The company's products cover a range of SiC applications, including power devices, modules, and systems. They specialize in designing and manufacturing SiC products that meet the highest quality standards, specifically for the automotive and industrial markets.{Company} has developed a range of SiC products that are tailored to meet the growing demand for high-performance electric vehicles. Their products offer high efficiency, superior reliability, and an extended lifespan compared to traditional silicon-based products. Their SiC MOSFETs, in particular, have been designed specifically for the electric vehicle market, offering high performance, compact size, and high reliability.In addition to their SiC MOSFETs, {company} has a range of SiC products that are suitable for a variety of applications, including renewable energy, industrial automation, and high-frequency communications. Their SiC modules are highly efficient and compact, making them ideal for use in electric vehicle chargers, battery management systems, and other high-power applications.{Company} is also involved in the development of next-generation SiC technology, including the development of 200mm SiC wafer production technology. This technology is expected to significantly increase the supply of SiC wafers, making them more accessible and cost-effective for a wider range of applications.In conclusion, the demand for high-performance electric vehicles is driving the development of new power electronics Technologies. SiC is emerging as a key player in this space, offering high efficiency, superior reliability, and an extended lifespan compared to traditional semiconductor materials. Companies like {company} have invested heavily in SiC technology and are developing innovative products that meet the demands of the rapidly growing electric vehicle market. As the market continues to expand, SiC is expected to play an increasingly important role in driving the next phase of electric vehicle growth.

Discover the Uses and Benefits of High Purity Graphite

High Purity Graphite: The Essential Material for Emerging TechnologiesHigh purity graphite is a vital material for a wide range of emerging technologies, and one company at the forefront of its production is {Company Name}. With a commitment to sustainability and innovation, {Company Name} is playing a crucial role in meeting the growing global demand for high purity graphite.High purity graphite is an essential component in many cutting-edge technologies, including lithium-ion batteries, fuel cells, solar panels, and nuclear reactors. As these technologies continue to advance and become more widespread, the demand for high purity graphite is expected to skyrocket in the coming years. This presents a significant opportunity for companies like {Company Name} that are able to produce high quality graphite at scale.Founded in {Year}, {Company Name} is a leading producer of high purity graphite with a strong focus on sustainability and environmental responsibility. The company prides itself on its commitment to minimizing its environmental impact through the use of innovative production processes and renewable energy sources. With a vertically integrated business model that encompasses mining, processing, and distribution, {Company Name} is able to control the entire production process and ensure the highest quality standards are met.One of {Company Name}'s key strengths is its extensive experience and expertise in the field of graphite production. The company has invested heavily in research and development to develop cutting-edge technologies for refining graphite to the highest purity levels. By continuously improving its production processes, {Company Name} has been able to achieve exceptional levels of purity in its graphite products, making them highly sought after in the market.In addition to its commitment to sustainability and innovation, {Company Name} also places a strong emphasis on corporate social responsibility. The company is dedicated to supporting the communities in which it operates, and it has implemented various social and educational programs to benefit local residents. By fostering positive relationships with its stakeholders and prioritizing the well-being of its employees and local communities, {Company Name} is setting a positive example for the industry as a whole.As the demand for high purity graphite continues to rise, {Company Name} is well positioned to capitalize on this growing market opportunity. With its proven track record of producing high quality graphite in an environmentally responsible manner, the company is poised to become a key player in the global graphite industry. By leveraging its expertise, commitment to sustainability, and dedication to corporate social responsibility, {Company Name} is primed for continued success and growth in the years to come.In conclusion, high purity graphite is a crucial material for a wide range of emerging technologies, and {Company Name} is a leading producer in the industry. With its focus on sustainability, innovation, and corporate social responsibility, the company is well positioned to meet the growing global demand for high purity graphite. As the market for high purity graphite continues to expand, {Company Name} is set to play a key role in driving the industry forward and shaping the future of emerging technologies.

How Different Temperatures Affect Lithium Iron Phosphate-Graphite Battery Degradation: A Study on Charging and Discharging

Lithium Iron Phosphate (LFP) batteries are one of the most promising energy storage solutions for electric vehicles and home energy systems. These batteries are known for their high power density, long cycle life, and low risk of explosion. However, the performance of LFP batteries can degrade over time due to various factors, including temperature.In this article, we will discuss the effect of charging and discharging LFP batteries at different temperatures on their degradation. Specifically, we will focus on the role of graphite boat for Lithium Iron Phosphate Battery in this process.LFP batteries are composed of several components, including a cathode, an anode, a separator, and an electrolyte. The cathode material in LFP batteries is made of lithium iron phosphate, while the anode is typically made of graphite. Graphite is chosen as the anode material because of its ability to intercalate (store) lithium ions during charging and release them during discharging.During the charging process, lithium ions are transferred from the cathode to the anode, where they are stored in the graphite matrix. The charging process generates heat, which can increase the temperature of the battery. If the battery temperature exceeds a certain threshold, it can cause thermal runaway, leading to an explosion or fire.Similarly, during the discharging process, lithium ions are released from the anode and travel back to the cathode. This process also generates heat, which can increase the temperature of the battery. If the battery temperature drops too low, it can affect the efficiency of the battery, leading to a shorter cycle life.In general, it is recommended to charge LFP batteries at a moderate temperature range of 10°C to 30°C. Charging at higher temperatures can lead to accelerated degradation of the battery, while charging at lower temperatures can reduce the capacity of the battery. The same guidelines apply to discharging LFP batteries.The graphite boat for Lithium Iron Phosphate Battery has an important role to play in this process. The graphite boat acts as a container for the anode material, protecting it from external factors such as temperature, humidity, and dust. The quality of the graphite boat can significantly affect the performance of the battery. A high-quality graphite boat can provide better thermal insulation, reduce the thermal gradient within the battery, and prevent the leakage of lithium ions.In conclusion, the charging and discharging temperatures of LFP batteries play a crucial role in their degradation. Charging at moderate temperatures can help prolong the cycle life of the battery, while discharging at low temperatures can reduce its efficiency. The graphite boat for Lithium Iron Phosphate Battery is an essential component that can help protect the anode material from external factors and improve the overall performance of the battery.