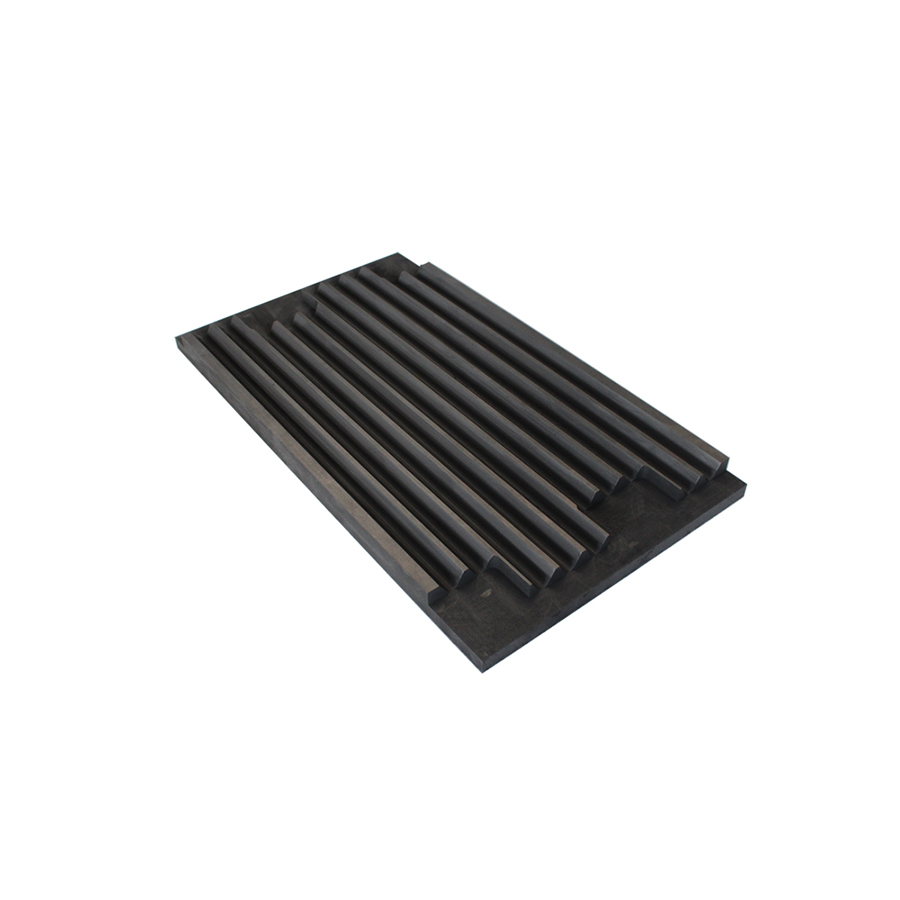

Innovative Porous Coating Graphite Mould: A New Advancement in Mould Technology

By:Admin

With a history of over 20 years in the industry, {Company Name} has established itself as a leader in the production and distribution of Porous Coating Graphite Mould. The company has a strong focus on research and development, constantly striving to improve its products and stay ahead of the curve in terms of technological advancements. This commitment to innovation has allowed {Company Name} to become a trusted partner for manufacturers looking to improve their production processes.

Porous Coating Graphite Mould is a versatile tool that can be used in a wide range of manufacturing applications. Whether it's producing automotive parts, aerospace components, or medical devices, Porous Coating Graphite Mould offers manufacturers the flexibility and precision they need to meet their production demands. The technology works by allowing gas to pass through the mould, which results in a uniform and consistent coating on the metal part being produced. This ensures that the final product has a smooth and flawless surface finish, free from imperfections or defects.

One of the key advantages of using Porous Coating Graphite Mould is its ability to produce complex and intricate metal parts with high precision. This is particularly important in industries such as aerospace and medical manufacturing, where the smallest flaw in a part can have serious consequences. By using Porous Coating Graphite Mould, manufacturers can ensure that their parts meet the highest quality standards, while also reducing production time and costs.

In addition to its precision and versatility, Porous Coating Graphite Mould also offers cost savings for manufacturers. The technology allows for a more efficient use of materials, reducing waste and minimizing the need for additional finishing processes. This results in lower production costs and a more sustainable manufacturing process overall.

{Company Name} is committed to providing its customers with the highest quality Porous Coating Graphite Mould, backed by exceptional customer service and support. The company works closely with its clients to understand their specific production needs and develop customized solutions to meet those requirements. With a team of experienced engineers and technical experts, {Company Name} is able to provide comprehensive support to its customers, from initial consultation to ongoing maintenance and support.

As the manufacturing industry continues to evolve and demand for high-quality metal parts grows, Porous Coating Graphite Mould is set to play a crucial role in shaping the future of manufacturing. With its precision, versatility, and cost-saving benefits, this innovative technology is helping manufacturers stay ahead of the curve and meet the ever-increasing demands of their customers. And with {Company Name} at the forefront of this technological revolution, manufacturers can trust that they have a reliable partner to support their production needs.

Company News & Blog

Discover the Latest Innovations in Sintering Graphite Crucibles from China

China Sintering Graphite Crucible Boosting Industrial Growth and Efficiency(Company Introduction)With over two decades of experience in the graphite industry, our company has become a leading manufacturer and supplier of high-quality graphite products in China. We specialize in producing sintering graphite crucibles, which have gained widespread recognition for their exceptional performance and durability. Our commitment to excellence and innovation has propelled us to the forefront of the industry, enabling us to cater to a diverse range of industrial needs.(Graphite Crucible Market Overview)The global graphite crucible market has been witnessing significant growth in recent years, driven by the expanding industrial sector and the increased demand for efficient and reliable crucibles in various manufacturing processes. Graphite crucibles play a vital role in industries such as foundries, metallurgy, chemicals, and jewelry making, where they are used for melting, casting, and holding molten metals and alloys.(Features and Benefits of China Sintering Graphite Crucibles)Our sintering graphite crucibles offer a wide range of features and benefits that distinguish them from other crucible options available in the market. The sintering process enhances the structure and properties of the graphite, making it denser and more resistant to thermal shock. This ensures uniform heat distribution, improved thermal conductivity, and higher mechanical strength, resulting in superior performance and longer crucible lifespans.Additionally, our graphite crucibles exhibit excellent corrosion resistance, enabling them to withstand the corrosive effects of various molten metals and alloys. Their non-wetting property prevents metal contamination, ensuring the purity of the final product. Moreover, the high thermal stability and low coefficient of thermal expansion of our crucibles make them highly reliable even under extreme temperature conditions.(Application and End-User Industries)China sintering graphite crucibles find extensive application in numerous industries:1. Foundries: Graphite crucibles are commonly used in foundries for melting and casting processes. Their superior thermal properties and resistance to thermal shock make them ideal for handling high-temperature alloys.2. Metallurgy: Crucibles are essential in metallurgical laboratories for conducting various analytical tests and experiments. The excellent thermal conductivity of graphite ensures accurate and precise results.3. Chemical Industry: The chemical industry utilizes graphite crucibles for various chemical reactions, including melting and evaporation. The crucibles' resistance to corrosive chemicals and high temperatures ensures the safety and efficiency of these processes.4. Jewelry Making: Graphite crucibles are widely used in jewelry making for casting precious metals such as gold, silver, and platinum. Their excellent thermal properties and smooth surface finish allow for precise casting and minimal product loss.(Advantages of Choosing China Sintering Graphite Crucibles)By selecting China sintering graphite crucibles, industrial customers can enjoy several advantages:1. Competitive Pricing: Our graphite crucibles are competitively priced without compromising on quality. This allows businesses to lower their production costs and improve overall profitability.2. ISO Certification: Our company holds ISO 9001:2015 certification, which guarantees that our crucibles meet the highest international quality standards. This assures customers of consistent product performance and reliability.3. Customization Options: We understand that different industries have unique requirements. Therefore, we offer customization options to tailor our graphite crucibles to specific customer needs, be it size, shape, or other specifications.4. Excellent Customer Service: Our dedicated customer service team ensures prompt response and efficient handling of inquiries, orders, and after-sales services. We strive to cultivate long-term partnerships with our clients by providing exceptional service and support.(Future Outlook)Looking ahead, the demand for graphite crucibles is expected to continue growing, driven by ongoing industrialization and advancements in manufacturing technologies. As a leading manufacturer, we are committed to meeting this growing demand by further enhancing our production capabilities and expanding our product offerings. We will continue to invest in research and development, leveraging the latest innovations to provide even more advanced and efficient graphite crucibles to our customers.In conclusion, China sintering graphite crucibles have emerged as a reliable and efficient solution for various industries' melting, casting, and holding needs. With their exceptional performance, durability, and competitive pricing, these crucibles have become indispensable in improving industrial growth and efficiency. As our company continues to innovate and expand, we look forward to serving both domestic and international markets with the highest quality graphite crucibles.

High-Quality Nitrogen Analyzer Graphite Crucible for Accurate Measurement

Nitrogen Analyzer Graphite Crucible: The Key to Accurate Nitrogen AnalysisIn the world of modern manufacturing and production, accurate testing and analysis are essential for ensuring the quality and performance of materials and products. This is especially true in the case of nitrogen analysis, which plays a crucial role in a wide range of industries, including steel production, chemical manufacturing, and environmental monitoring.The key to accurate nitrogen analysis lies in the quality and reliability of the equipment used in the testing process. One essential piece of equipment that has revolutionized the field of nitrogen analysis is the Nitrogen Analyzer Graphite Crucible. This innovative tool has been developed to provide precise and reliable results, making it an indispensable asset for companies and research institutions around the world.The Nitrogen Analyzer Graphite Crucible is a specialized piece of equipment that is used in conjunction with nitrogen analyzers to measure the nitrogen content of various materials. The crucible is designed to withstand high temperatures and harsh conditions, ensuring that accurate and consistent results can be obtained with each analysis.One of the key features of the Nitrogen Analyzer Graphite Crucible is its durability and resistance to chemical reactions. This ensures that the crucible can be used repeatedly without any loss of accuracy or reliability, making it a cost-effective solution for laboratories and industrial facilities.In addition to its durability, the Nitrogen Analyzer Graphite Crucible is also designed to provide accurate and precise measurements. This is achieved through the use of high-quality graphite material, which is known for its excellent thermal conductivity and stability. The crucible is also designed to minimize contamination and ensure that the nitrogen content of the sample is accurately measured.The Nitrogen Analyzer Graphite Crucible is compatible with a wide range of nitrogen analyzers, making it a versatile and widely applicable tool for various industries. Whether it is used in steel production to monitor nitrogen levels in the metal, in chemical manufacturing to verify the purity of substances, or in environmental monitoring to assess nitrogen levels in soil and water samples, the crucible proves to be an invaluable asset.One of the leading providers of the Nitrogen Analyzer Graphite Crucible is an industry-leading company that has established a strong reputation for its commitment to quality and innovation. With a focus on research, development, and manufacturing, the company is dedicated to providing state-of-the-art solutions for nitrogen analysis and other analytical processes.The company's Nitrogen Analyzer Graphite Crucible is a testament to its dedication to excellence and its ability to meet the needs of its customers. With a strong emphasis on quality control and performance testing, the company ensures that each crucible meets the highest standards of reliability and accuracy.In addition to the Nitrogen Analyzer Graphite Crucible, the company offers a comprehensive range of equipment and accessories for nitrogen analysis, including nitrogen analyzers, sample preparation tools, and calibration standards. This complete suite of products enables customers to achieve precise and reliable results in their nitrogen analysis processes, ultimately leading to improved quality control and production efficiency.The Nitrogen Analyzer Graphite Crucible is just one example of the company's commitment to innovation and excellence in analytical science. With a strong focus on research and development, the company continues to push the boundaries of technology to develop new and improved solutions for analytical testing, ultimately benefiting industries and research institutions around the world.In conclusion, the Nitrogen Analyzer Graphite Crucible is a vital tool for accurate nitrogen analysis in a wide range of industries. Its durability, accuracy, and compatibility with various nitrogen analyzers make it an essential asset for companies and research institutions seeking reliable and precise results. With the support of industry-leading companies like {}, the future of nitrogen analysis looks bright, promising advancements in quality control and production efficiency.

High-Quality Graphite Box for Ndfeb: What You Need to Know

Leading Graphite Box Company Introduces Innovative Solution for Ndfeb MaterialsGraphite Box Company is pleased to introduce an innovative solution for the transportation and storage of Ndfeb (neodymium-iron-boron) materials. Ndfeb is a type of rare earth magnet that is widely used in various industries, including electronics, automotive, and renewable energy. Due to their high magnetic properties, Ndfeb materials require special care and protection during transportation and storage to prevent damage and ensure their performance.Graphite Box Company has developed a new and advanced packaging solution specifically designed for Ndfeb materials. The company's graphite boxes are made from high-quality graphite material that provides excellent thermal and electrical conductivity, high mechanical strength, and chemical resistance. These properties make graphite boxes an ideal choice for the transportation and storage of Ndfeb materials, as they offer superior protection against external factors such as temperature fluctuations, moisture, and physical impact.The innovative design of Graphite Box Company's packaging solution also includes custom foam inserts that are precisely engineered to securely hold Ndfeb materials in place, preventing them from shifting or coming into contact with each other during transportation. This ensures that the magnetic properties of the materials remain uncompromised and that they arrive at their destination in optimal condition.In addition to providing superior protection, Graphite Box Company's packaging solution is also designed with sustainability in mind. The graphite material used in the boxes is highly durable and long-lasting, reducing the need for frequent replacement and minimizing environmental impact. Furthermore, the company is committed to using eco-friendly production processes and materials, making their packaging solution a truly sustainable choice for businesses that prioritize environmental responsibility."We are thrilled to introduce our new graphite boxes for the transportation and storage of Ndfeb materials," said [company spokesperson]. "We understand the unique challenges associated with handling Ndfeb materials, and our goal is to provide a reliable and sustainable packaging solution that meets the specific needs of our customers. Our graphite boxes offer unmatched protection and peace of mind, allowing businesses to transport and store Ndfeb materials with confidence."Graphite Box Company has a long-standing reputation for delivering high-quality, reliable packaging solutions for various industries. The company's commitment to innovation, sustainability, and customer satisfaction has established them as a leading provider of protective packaging solutions, and their new graphite boxes for Ndfeb materials further solidify their position in the market.In conclusion, Graphite Box Company's innovative packaging solution for Ndfeb materials is set to revolutionize the way businesses handle and transport these valuable and sensitive materials. With their superior protection, sustainable design, and commitment to customer satisfaction, Graphite Box Company continues to be a trusted partner for businesses seeking reliable and innovative packaging solutions. Businesses can now confidently transport and store Ndfeb materials knowing that they are protected by the highest quality graphite boxes on the market.

Durable High Density Graphite Tubes for Industrial Use

High Density Graphite Tubes Utilized in Cutting-Edge TechnologiesGraphite has long been recognized for its exceptional properties, such as high thermal conductivity, low expansion, and chemical resistance. These qualities make it an ideal material for a wide range of industrial applications, particularly in the high-tech sector. One company at the forefront of utilizing graphite in cutting-edge technologies is {Company Name}.{Company Name} is a leading manufacturer of high density graphite tubes. These tubes are produced using the latest technological advancements and are designed to meet the demanding requirements of various industries, including aerospace, semiconductor, and energy.The high density graphite tubes manufactured by {Company Name} are known for their high mechanical strength, excellent thermal stability, and low thermal expansion. This makes them ideal for use in high-temperature applications, where traditional materials may not be suitable.One of the key industries that benefit from the use of high density graphite tubes is the aerospace sector. These tubes play a crucial role in the production of advanced aerospace components, such as rocket nozzles, re-entry vehicle components, and heat shields. The exceptional thermal conductivity and resistance to high temperatures make graphite tubes an essential material for these applications.In addition to aerospace, the semiconductor industry also relies on high density graphite tubes for various manufacturing processes. The tubes are used in the production of semiconductor components, such as silicon ingot molds, crucibles, and heating elements. The high thermal stability and resistance to chemical corrosion make graphite an ideal material for these critical applications.Furthermore, the energy sector is another key industry that benefits from the utilization of high density graphite tubes. These tubes are used in the production of components for high-temperature furnaces, heating elements for industrial processes, and electrodes for electric arc furnaces. The superior thermal conductivity and mechanical strength of graphite tubes make them indispensable in these applications.{Company Name} takes pride in its state-of-the-art manufacturing facilities, which are equipped with advanced machinery and quality control systems. The company's production processes are optimized to ensure the highest level of precision and consistency in the manufacturing of high density graphite tubes. Additionally, {Company Name} is committed to continuous research and development to further improve the performance and properties of its graphite tubes.The dedication to excellence and quality has earned {Company Name} a strong reputation in the industry. The company has established a global presence and serves customers in various countries around the world. {Company Name} has built strong relationships with its clients, providing them with customized solutions and unparalleled technical support.In conclusion, the utilization of high density graphite tubes in cutting-edge technologies is vital for a wide range of industries, including aerospace, semiconductor, and energy. {Company Name} has emerged as a leading manufacturer of these high-performance graphite tubes, thanks to its commitment to excellence, advanced manufacturing capabilities, and strong customer relationships. As technology continues to advance, the demand for high density graphite tubes is expected to grow, and {Company Name} is well-positioned to meet these evolving needs.

High-quality Graphite Die for Industrial Use

Graphite Die, a highly specialized component used in various industrial processes, is an essential tool for precision manufacturing in diverse industries such as automotive, aerospace, and electronics. The Graphite Die is a critical element in the production of complex parts and components, providing the necessary precision and durability to meet the high standards of modern manufacturing.Since its establishment, {Company Name} has been at the forefront of the graphite die manufacturing industry, providing high-quality products and services to its clients worldwide. With a strong focus on innovation and technology, the company has successfully developed advanced production techniques and state-of-the-art materials to meet the evolving demands of its customers.The Graphite Die is an integral part of the manufacturing process, used in a wide range of applications such as die casting, metal extrusion, and glass molding. With its unique properties, including high temperature resistance, low coefficient of thermal expansion, and excellent machinability, graphite has become the material of choice for manufacturing precision dies.{Company Name} has been committed to providing its clients with the highest quality graphite dies, utilizing advanced manufacturing processes and stringent quality control measures to ensure the reliability and performance of its products. The company's team of skilled engineers and technicians work closely with its clients to understand their specific needs and requirements, offering customized solutions that meet the most demanding standards of precision and quality.The use of graphite dies in the manufacturing process offers numerous advantages, including improved product quality, reduced production time, and enhanced cost-efficiency. With its unique combination of properties, graphite provides the necessary strength and durability to withstand the high pressures and temperatures involved in industrial processes, resulting in superior performance and longer tool life.In addition to its core products, {Company Name} also offers a range of value-added services to its clients, including die design and engineering, prototyping, and technical support. This comprehensive approach enables the company to provide a complete solution to its clients, from the initial design phase to the final production stage, ensuring the highest level of quality and accuracy throughout the entire process.As a leading supplier of graphite dies, {Company Name} has established a strong reputation for its commitment to quality, innovation, and customer satisfaction. The company's continued investment in research and development, along with its dedication to excellence, has positioned it as a trusted partner for a wide range of industries, from automotive and aerospace to electronics and consumer goods.With the increasing demand for high-precision manufacturing solutions, the role of graphite dies in modern industry continues to be pivotal. {Company Name} remains dedicated to meeting the evolving needs of its clients, delivering reliable and high-performance graphite dies that contribute to the success of their manufacturing operations.In conclusion, the Graphite Die plays an essential role in the production of precision parts and components, serving as a critical tool in various industrial processes. {Company Name}'s commitment to excellence and innovation has positioned it as a leading supplier of graphite dies, offering high-quality products and services to meet the diverse needs of its clients worldwide. With its advanced manufacturing techniques and comprehensive range of value-added services, the company continues to drive the advancement of the graphite die industry, providing innovative solutions that contribute to the success of modern manufacturing.

Top-quality Isostatic Metal Casting Molds for High-performance EDM Graphite Marble Mold

High Performance EDM Graphite Marble Mold: A Boon for Isostatically Bearing Metal Casting MoldsMetal casting is one of the most widely used techniques employed for producing various metal products. It involves pouring molten metal into a mold and allowing it to solidify into the desired shape. However, this process is not as simple as it sounds. The metal has to be cast with precision to ensure that the final product meets the desired specifications. One way to ensure this is by using high-quality graphite molds. Graphite molds are extensively used in the metal casting industry due to their exceptional properties such as high thermal conductivity, excellent machinability, and low thermal expansion coefficient. The recent development of High-Performance EDM Graphite Marble Mold has revolutionized the industry.High-Performance EDM Graphite Marble Mold is one of the most advanced forms of graphite molds available today. This type of mold is made using high-quality isostatic graphite, which is a versatile and durable material. It is ideally suited for producing intricate and complex metal castings. The use of isostatic graphite ensures that the molds are free from any internal defects or cracks, which can affect the quality of the final product.The High-Performance EDM Graphite Marble Mold also employs the technique of Electrical Discharge Machining (EDM) to produce a precise and accurate mold. EDM is an advanced machining process in which electrical discharges are used to shape the material. It is an effective process for producing complex shapes with very high accuracy. The use of EDM in graphite mold production ensures that the molds are of the highest quality and precision.One of the key advantages of using High-Performance EDM Graphite Marble Mold is its exceptional thermal conductivity. Graphite has one of the highest thermal conductivity rates of any material. This allows the mold to quickly heat up and cool down, which is essential for producing metal castings with a high degree of accuracy. Moreover, the low thermal expansion coefficient of graphite enables the mold to maintain its shape and dimensions even at high temperatures.Isostatically Bearing Metal Casting Molds are particularly challenging to produce due to their complex geometry and tight tolerances. However, the use of High-Performance EDM Graphite Marble Mold has made this process much more manageable. The exceptional precision and accuracy of these molds make them ideal for producing isostatically bearing metal castings with a high degree of quality and consistency.The production of High-Performance EDM Graphite Marble Mold is a highly specialized process that requires expertise and experience. It involves the use of advanced equipment and techniques such as CAD modeling, CNC machining, and EDM. Therefore, it is essential to work with a reputable and experienced custom graphite molds manufacturer who can deliver high-quality molds tailored to your specific requirements.In conclusion, the development of High-Performance EDM Graphite Marble Mold has improved the quality and consistency of isostatically bearing metal casting molds. These molds offer exceptional precision, accuracy, and thermal conductivity, which are essential for producing high-quality metal castings. The use of isostatic graphite and EDM technology ensures that these molds are of the highest quality and can meet even the most demanding requirements of the industry. Therefore, the widespread adoption of High-Performance EDM Graphite Marble Mold is expected to significantly improve the efficiency and productivity of the metal casting industry.

Innovative Graphite Box Enables Efficient Storage of Carbonized Powder

LONDON, UK - Graphite boxes have long been considered as one of the best choices for carbonized powder packaging, as they offer a high level of durability and protection. The increasing demand for carbonized powder, coupled with the need for safe and secure packaging, has led to a surge in the development and production of graphite boxes. One such manufacturer is a company that specializes in the production of high-quality graphite products for industrial use.This company has recently launched its latest product, a graphite box designed specifically for carbonized powder. This new offering promises to provide customers with a high-quality packaging solution that ensures maximum protection for their powdered products.The graphite box is made from premium-quality graphite, which is known for its high strength and durability. This ensures that the box can withstand the rigors of transportation and storage without compromising the quality of the product inside. Additionally, the box has been designed to be airtight, which prevents the powder from getting contaminated by external elements.Speaking about the new product, the company's spokesperson said, "We are thrilled to introduce our latest offering to the market. This graphite box is the culmination of years of research and development aimed at providing our customers with the best possible packaging solution for their carbonized powder. We are confident that this product will meet and exceed the expectations of our customers."The spokesperson also spoke about the company's commitment to sustainability, saying, "We take our role as a responsible manufacturer very seriously. That's why we use only eco-friendly materials in our production processes. By doing so, we help reduce our environmental impact while offering our customers high-quality products that meet their needs."The company, which has been in the graphite manufacturing industry for over a decade, has earned a reputation for providing high-quality, innovative products to its customers. Its portfolio of products includes a range of graphite products such as crucibles, molds, and electrodes, which are used in various industrial applications.The launch of this new product is expected to further strengthen the company's position in the market. With the demand for carbonized powder set to rise in the coming years, the company is well-positioned to capitalize on this growth by providing its customers with a reliable, high-quality packaging solution.In conclusion, the launch of the graphite box for carbonized powder by this company is a significant development that underscores its commitment to providing innovative and sustainable solutions to its customers. With this product, the company has set a new standard in the packaging industry and is poised to continue leading the way in graphite manufacturing for years to come.

High-Quality Graphite for EDM Machining - Shop with Confidence on eBay

EDM Graphite: Your Partner for High-Precision MachiningWhen it comes to precision machining, EDM graphite has become an increasingly popular material of choice for both small and large manufacturers. EDM (Electrical Discharge Machining) graphite is a unique form of synthetic graphite that is used to manufacture electrodes and other components that are essential to the process of electrically conductive machining.EDM graphite is known to exhibit excellent thermal conductivity, high resistance to wear, and superior hardness characteristics. It is also non-porous and has a high resistance to corrosion, making it ideal for use in a wide range of industrial applications.Advantages of EDM GraphiteOne of the primary benefits of using EDM graphite in high-precision machining processes is its ability to deliver superior machining accuracy. Its unique composition allows it to conduct heat away from the point of contact and maintain dimensional stability during extended machining processes.EDM graphite also offers superior electrical conductivity, which enables the user to produce highly complex geometries and intricate shapes with unmatched precision.Another significant advantage of EDM graphite is its ability to support high-speed machining processes. EDM graphite can maintain its structural integrity even under high-speed machining conditions, which reduces machining time and improves overall productivity.Applications of EDM GraphiteEDM graphite is widely used in various industries, including aerospace, defense, automotive, and medical.In the aerospace industry, EDM graphite is used to manufacture components such as turbines, engine parts, and wing components with fine tolerances and complex geometries.The defense industry also leverages EDM graphite to produce intricate parts for radar systems, guided missiles, and various other electronic components.In the automotive industry, EDM graphite is widely used to fabricate mold cavities for various car parts such as dashboard panels, door handles, and other critical components.The medical industry also relies on EDM graphite for the production of precise surgical instruments and implants that require strict manufacturing tolerances.ConclusionEDM graphite is a critical material that is essential to a wide range of precision machining applications. Its superior thermal conductivity, electrical conductivity, and hardness characteristics make it an ideal material choice for manufacturers looking to improve their machining productivity without sacrificing quality.If you are looking for reliable and high-quality EDM graphite products, be sure to work with a reputable supplier known for delivering consistently excellent products and services.

High-Quality Graphite Blocks Made in China: Latest Industry News

China Graphite Block, a leading company in the graphite block industry, has recently announced a significant breakthrough in their production process that is set to revolutionize the market. With a focus on providing high-quality graphite blocks for various industrial applications, the company has continuously invested in research and development to improve their manufacturing techniques and meet the growing demands of their global customer base.Established in [], China Graphite Block has quickly emerged as a frontrunner in the graphite block industry, setting new standards for product quality and customer service. The company's state-of-the-art production facilities and a team of experienced engineers and technicians have enabled them to develop cutting-edge graphite block solutions that cater to the needs of diverse industries, including metallurgy, chemical, aerospace, and electronics.The recent breakthrough in China Graphite Block's production process is the result of extensive research and development efforts aimed at enhancing the performance and durability of their graphite blocks. By leveraging advanced manufacturing technologies and innovative materials, the company has successfully developed a new generation of graphite blocks that offer superior thermal conductivity, high mechanical strength, and excellent resistance to thermal shock and chemical corrosion.The enhanced performance attributes of the new graphite blocks make them ideal for a wide range of industrial applications, including but not limited to the production of crucibles, EDM electrodes, continuous casting dies, and heat exchangers. These high-performance graphite blocks are designed to withstand extreme operating conditions and deliver exceptional reliability, thereby helping companies improve their manufacturing processes and achieve higher productivity and efficiency.Furthermore, China Graphite Block's new production process also emphasizes environmental sustainability and energy efficiency. By optimizing the use of raw materials and implementing eco-friendly manufacturing practices, the company is dedicated to minimizing its environmental footprint while producing high-quality graphite blocks that meet the requirements of environmentally conscious industries.As a leading player in the global graphite block market, China Graphite Block is committed to maintaining its competitive edge through continuous innovation and customer-centric approaches. By focusing on research and development, the company aims to stay ahead of industry trends and offer cutting-edge solutions that address the evolving needs of its customers.In addition to its technological advancements, China Graphite Block is also renowned for its commitment to customer satisfaction. With a strong emphasis on quality control and product consistency, the company has established a solid reputation for delivering premium graphite blocks that meet the highest industry standards. Furthermore, its dedicated customer support team works closely with clients to understand their specific requirements and provide customized solutions tailored to their individual needs.The recent breakthrough in China Graphite Block's production process has drawn widespread attention from industry professionals and customers alike. Many have lauded the company for its relentless pursuit of excellence and its ability to push the boundaries of innovation in the graphite block industry.Looking ahead, China Graphite Block is poised to continue its expansion into new markets and further strengthen its position as a global leader in the graphite block industry. With a strong focus on research and development, customer satisfaction, and environmental sustainability, the company is well-equipped to meet the evolving demands of the industry and maintain its reputation for excellence.