Top Quality Fine-Grained Graphite for Multiple Applications

By:Admin

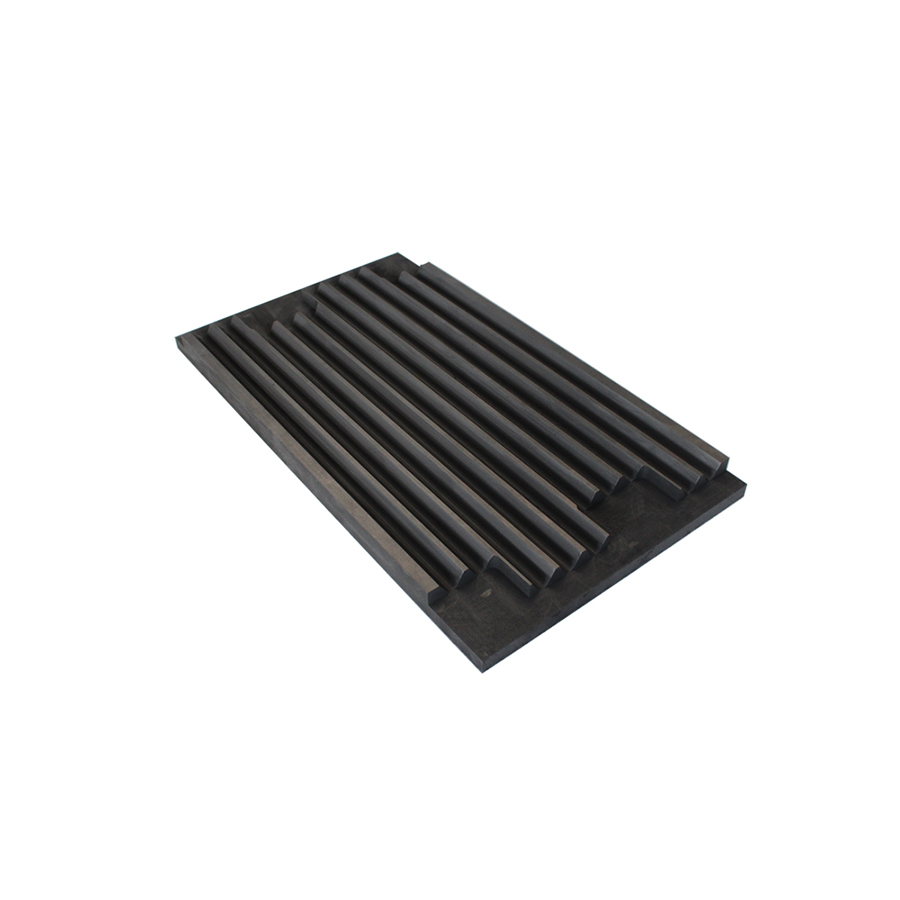

Graphite is a form of carbon that has been used for centuries in various industries due to its unique properties. It is known for its high thermal and electrical conductivity, as well as its lubricating properties, making it a highly versatile material. In recent years, the demand for fine-grained graphite has been on the rise, especially in industries such as electronics, aerospace, and energy storage.

One company that has been at the forefront of providing high-quality fine-grained graphite is {}. With a strong focus on research and development, they have been able to produce graphite materials that meet the stringent requirements of modern industries. Their fine-grained graphite products have been widely used in applications such as lithium-ion batteries, fuel cells, and thermal management solutions.

In the field of electronics, fine-grained graphite has become an essential component in the manufacturing of electronic devices. Its high thermal conductivity and heat dissipation properties make it an ideal material for use in smartphones, tablets, and other electronic gadgets. With the increasing demand for smaller and more powerful electronic devices, the need for fine-grained graphite has never been greater.

In the aerospace industry, fine-grained graphite plays a crucial role in the manufacturing of aircraft components. Its high strength-to-weight ratio and ability to withstand high temperatures make it a preferred material for use in aircraft engines, avionics, and structural components. As the aerospace industry continues to advance, the demand for high-quality fine-grained graphite is expected to increase significantly.

Another industry that has seen a growing demand for fine-grained graphite is energy storage. With the rise of electric vehicles and renewable energy sources, the need for high-performance energy storage solutions has become more pronounced. Fine-grained graphite is used in the production of lithium-ion batteries, which are crucial for powering electric vehicles and storing energy from renewable sources such as solar and wind. As the demand for clean energy continues to grow, the market for fine-grained graphite is projected to expand rapidly.

{}, with its cutting-edge technology and expertise in graphite materials, has been able to meet the evolving needs of these industries. Their fine-grained graphite products are known for their consistent quality and performance, making them a trusted partner for manufacturers and researchers alike. By continually investing in research and development, they have been able to stay ahead of the curve and provide innovative graphite solutions that drive progress in various industries.

In addition to providing high-quality graphite materials, {} is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their production processes, ensuring minimal impact on the environment. This commitment to sustainability has made them a preferred supplier for companies looking to minimize their carbon footprint and support sustainable development.

As the global demand for fine-grained graphite continues to grow, companies like {} are well-positioned to play a pivotal role in shaping the future of various industries. With their advanced technology, dedication to quality, and commitment to sustainability, they are poised to be a key player in the graphite market for years to come.

Company News & Blog

High-performance Graphite Heat Exchange Blocks for Efficient Heat Transfer

Heat Exchange Graphite Block (brand name removed) is a critical component in many industrial processes, and a company that has been at the forefront of manufacturing and supplying high-quality graphite products is {}.{} is a leading manufacturer of graphite products, with a strong expertise in producing Heat Exchange Graphite Blocks that are used in various industries such as chemical, metallurgical, and environmental protection. The company has a state-of-the-art manufacturing facility that is equipped with advanced technology and a skilled workforce, allowing them to produce graphite products that meet the highest quality standards.The Heat Exchange Graphite Blocks produced by {} are known for their excellent thermal conductivity, high temperature resistance, and corrosion resistance. These properties make them ideal for use in heat exchangers, where they play a crucial role in transferring heat from one fluid to another without direct contact between the fluids.One of the key advantages of {}'s Heat Exchange Graphite Blocks is their durability and longevity. These blocks are designed to withstand harsh operating conditions and are highly resistant to thermal shock and deformation. This makes them a reliable choice for industries that require consistent and efficient heat exchange processes.In addition to its exceptional product quality, {} is also committed to providing excellent customer service. The company works closely with its clients to understand their specific requirements and offers customized solutions to meet their needs. Whether it's designing a new graphite block or providing technical support, {} is dedicated to ensuring client satisfaction.With a strong focus on research and development, {} continuously strives to innovate and improve its graphite products. The company invests in cutting-edge technologies and has a team of experienced engineers and technicians who are dedicated to developing new and improved Heat Exchange Graphite Blocks.Furthermore, {} is also dedicated to sustainability and environmental responsibility. The company adheres to strict environmental standards in its manufacturing processes and ensures that its products have minimal impact on the environment. By using high-quality raw materials and implementing eco-friendly production practices, {} is committed to reducing its carbon footprint.As a leading player in the graphite industry, {} has built a strong reputation for delivering high-quality products and exceptional service. The company's Heat Exchange Graphite Blocks have been widely adopted by various industries, and its clientele includes some of the biggest names in the manufacturing and processing sectors.In conclusion, {} has established itself as a reliable and innovative manufacturer of Heat Exchange Graphite Blocks. With a focus on quality, customer satisfaction, and sustainability, the company is well-positioned to meet the growing demand for graphite products in industrial applications. As industries continue to seek efficient and reliable heat exchange solutions, {} remains a trusted partner in providing top-notch Heat Exchange Graphite Blocks.

Top Quality Graphite Moulds from China - The Latest in Moulding Technology

China Graphite Mould, a leading manufacturer of graphite molds for various industries, is proud to announce the expansion of their production capacity to meet the growing demand for their high-quality products. With a commitment to innovation and excellence, China Graphite Mould has established itself as a trusted supplier in the global market, providing reliable solutions for precision molding applications.Established in [year], China Graphite Mould has quickly gained a reputation for delivering superior graphite molds that are designed to meet the exacting specifications of their customers. The company's state-of-the-art manufacturing facilities are equipped with advanced technology and equipment, allowing them to produce molds with exceptional precision and accuracy. With a focus on quality control, China Graphite Mould ensures that every product that leaves their facility meets the highest standards of performance and durability.One of the key factors that sets China Graphite Mould apart from other manufacturers is their commitment to research and development. The company has a dedicated team of engineers and technical experts who are constantly working to improve their products and develop new and innovative solutions for their customers. This focus on innovation has enabled China Graphite Mould to stay ahead of the curve and anticipate the evolving needs of the industries they serve.In addition to their commitment to quality and innovation, China Graphite Mould places a strong emphasis on customer satisfaction. The company works closely with each of their clients to understand their unique requirements and provide tailored solutions that meet their specific needs. Whether it's a custom mold design or a large-scale production run, China Graphite Mould has the expertise and flexibility to deliver results that exceed expectations.The recent expansion of China Graphite Mould's production capacity comes in response to the increasing demand for their products in both domestic and international markets. With a growing customer base and a reputation for excellence, the company is poised for continued success and growth in the years to come. By investing in new technology and infrastructure, China Graphite Mould is committed to staying at the forefront of the industry and continuing to provide the highest quality graphite molds to their customers.As China Graphite Mould looks to the future, they remain dedicated to upholding their core values of quality, innovation, and customer satisfaction. With a relentless pursuit of excellence, the company is well-positioned to meet the evolving needs of the industries they serve and continue to be a preferred supplier for precision graphite molds.In conclusion, China Graphite Mould's expansion of their production capacity is a testament to their commitment to delivering high-quality products and customer-focused solutions. With a strong focus on innovation and a dedication to excellence, the company is well-positioned for continued success in the global market. As they continue to grow and evolve, China Graphite Mould remains a reliable partner for industries in need of precision graphite molds.

Small Electric Foundry for Bronze Casting: Tips and Techniques for Successful Results

Electric Foundry for Small Bronze Casting – Crucible for Melting BronzeBronze casting has been around for thousands of years. It is an ancient method of creating beautiful objects of art. Today, modern technology has made it easier for people to attempt bronze casting on their own. This is where a small electric foundry comes in handy. In this article, we will discuss how to make a small foundry for melting tin bronze.First, let's talk about the materials we will need. The following items are essential for building a small foundry:1. Soft fire bricks – These bricks are used to build the walls of the foundry. They are designed to withstand high temperatures.2. Insulator – This is a high-temperature insulation material that is used to line the inside of the foundry. It keeps the heat inside the foundry and prevents it from escaping.3. Nichrome coil – This is a heating element that is used to provide the heat needed to melt the tin bronze.4. Crucible – This is a container used to melt the bronze. It must be made of a material that can withstand high temperatures and is resistant to corrosion.Now that we have the materials, let's get started on building the foundry. The first step is to build a frame with the soft fire bricks. The size of the frame will depend on the size of the crucible. The frame should be built to support the crucible and the insulator.Next, place the insulator inside the frame. The insulator should be cut to size and placed inside the frame. It should be wrapped around the sides and the bottom of the frame. The insulator is what will keep the heat inside the foundry.After the insulator is in place, wrap the nichrome coil around the outside of the insulator. The coil should be wrapped tightly and evenly around the entire foundry. It should be wired to a 240V 10amp socket. The coil is what will provide the heat necessary to melt the tin bronze.Once the coil is in place, it's time to add the crucible. The crucible should be placed inside the foundry and centered on the coil. It should be large enough to hold the amount of bronze you plan to melt. The crucible should be made of a material that can withstand high temperatures, such as graphite or ceramic.Finally, turn on the power to the coil. The heat should be gradually increased until the bronze is fully melted. Once the bronze is melted, it's ready for casting.ConclusionBuilding a small foundry for melting tin bronze is not a difficult task. With the right materials, it can be done easily at home. By using a soft fire brick frame, high-temperature insulation, a nichrome coil, and a crucible, you can create your own electric foundry. This will allow you to create beautiful bronze objects of art in the comfort of your own home. So, get started today and let your creativity flow!

Unlocking the Potential of Special Graphite: A Game Changer in Industrial Applications

Special Graphite: A Game-Changer in Advanced IndustriesIn the ever-evolving world of advanced materials, Special Graphite has emerged as a key player, revolutionizing various industries with its exceptional properties and unparalleled performance. With an extensive range of applications and a strong focus on innovation, Special Graphite has positioned itself as a game-changer in the world of advanced industries.Founded in [], Special Graphite has quickly gained prominence as a leading manufacturer and supplier of premium-quality graphite products. Committed to delivering excellence, the company has set the benchmark for superior quality, reliability, and customer satisfaction.The success of Special Graphite can be attributed to its state-of-the-art manufacturing facilities, where cutting-edge technology and advanced production techniques are employed. The company's world-class research and development team consistently strive to develop innovative solutions that meet the ever-evolving needs of its customers. By combining their expertise in materials science and engineering, they have been able to create a diverse portfolio of graphite products that cater to a wide range of industries.One of the key strengths of Special Graphite lies in its ability to customize its products according to customer requirements. Whether it's a complex-shaped component or a specific composition, the company's manufacturing capabilities allow for the production of tailor-made solutions. This flexibility has earned Special Graphite a reputation for being a reliable partner, capable of meeting the most demanding specifications.The versatility of Special Graphite is evident in its application across various industries. In the electronics industry, Special Graphite is widely used for the production of components such as crucibles, heating elements, and electrodes. Its excellent thermal stability, high electrical conductivity, and low thermal expansion make it an ideal choice for these critical applications.In the automotive sector, Special Graphite plays a pivotal role in the manufacturing of lithium-ion batteries, fuel cells, and brake systems. With the increasing demand for electric vehicles, the need for high-performance graphite materials has surged. Special Graphite's products meet these requirements, enabling the automotive industry to move towards a sustainable future.The aerospace industry also benefits greatly from Special Graphite's capabilities. Its lightweight yet robust nature, coupled with its resistance to high temperatures and corrosive environments, makes it an indispensable material for aircraft components, satellite systems, and rocket propulsion. The reliability and performance of Special Graphite have been crucial in ensuring the safety and efficiency of aerospace operations.Moreover, Special Graphite has made significant contributions to the metallurgical industry, where its products find applications in the production of steel, aluminum, and other metals. The unique properties of Special Graphite, such as its high thermal conductivity and low friction coefficient, enhance the efficiency of these processes, resulting in higher productivity and cost savings for manufacturers.In addition to its wide range of applications, Special Graphite places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively pursues eco-friendly practices throughout its operations. By focusing on energy efficiency, waste reduction, and responsible sourcing of raw materials, Special Graphite acts as a responsible corporate citizen, contributing towards a more sustainable future.In conclusion, Special Graphite has emerged as a major player in the advanced materials industry, earning a reputation for its exceptional products and commitment to innovation. With its focus on customization, versatility, and sustainability, the company has successfully revolutionized several industries, including electronics, automotive, aerospace, and metallurgy. As the demand for high-performance materials continues to rise, Special Graphite remains at the forefront, driving advancements and enabling progress in advanced industries worldwide.

New Graphite Heating Rods Revolutionize Electrical Heating Technology

Title: Breakthrough Graphite Heating Rods Revolutionize the Heating IndustryIntroduction:With a relentless commitment to innovation, [Brand Name] has made a groundbreaking leap forward in the heating industry. The company's latest product, advanced graphite heating rods, promises to redefine the efficiency and effectiveness of heating systems in various applications. By combining cutting-edge technology with their expertise, [Brand Name] has once again established itself as a leader in the field. This article will provide an in-depth analysis of the features, benefits, and potential impact of these remarkable heating rods.Section 1: Background and SignificanceThe demand for heating systems that offer higher energy efficiency and reduced environmental impact has been increasing rapidly. Traditional heating methods, such as gas and electric furnaces, have limitations in terms of energy consumption and heat transfer efficiency. Recognizing this, [Brand Name] invested substantial resources in research and development to create graphite heating rods that would address these challenges.Section 2: Graphite Heating Rods: The Technology Behind the InnovationGraphite heating rods consist of advanced graphite materials that possess excellent thermal and electrical conductivity properties, making them ideal for heating applications. These rods have high resistance to extreme temperatures and provide even heat distribution, enabling them to heat up spaces quickly and efficiently. With a sleek and compact design, these rods offer superior durability and longevity, saving users from frequent replacements and repair costs.Section 3: Advantages and Benefits3.1 Energy Efficiency and Cost SavingsThe use of graphite heating rods significantly enhances energy efficiency, allowing users to lower energy consumption and ultimately reduce utility bills. With their remarkable heat conductivity, these heating rods eliminate heat loss during distribution, ensuring that the desired space is heated promptly, with no wasted energy.3.2 Rapid Heating and Enhanced ComfortGraphite heating rods heat up rapidly, reducing warm-up times considerably. This feature is particularly beneficial in industrial applications, where fast and efficient heating is crucial. Additionally, the remarkable heat distribution provided by these rods ensures that every corner of a room receives even warmth, providing optimal comfort to occupants.3.3 Environmental FriendlinessCompared to traditional heating methods, graphite heating rods produce minimal greenhouse gas emissions. By harnessing clean and renewable energy sources, such as electricity generated from solar or wind power, these rods contribute to a greener and more sustainable future.Section 4: Wide Range of ApplicationsGraphite heating rods offer a wide range of applications across different industries and settings. They are suitable for residential heating needs, commercial spaces like offices, hospitals, and shopping centers, as well as industrial processes where fast and precise heating is required. From homes to factories, the versatility and efficiency of these rods make them an ideal choice for any heating purpose.Section 5: The Future of Heating SystemsThe introduction of graphite heating rods marks a significant milestone in the heating industry. Its innovative design, energy efficiency, and environmental benefits position it as a promising alternative to traditional methods. The potential widespread adoption of these rods could revolutionize the heating industry, presenting a cleaner and more sustainable way to keep spaces warm.Conclusion:[Brand Name]'s graphite heating rods serve as a testament to their commitment to pushing the boundaries of innovation in the heating industry. With their exceptional thermal conductivity, energy efficiency, and environmental friendliness, these rods pave the way for a more sustainable and cost-effective heating solution. As the world continues to search for greener alternatives, [Brand Name]'s graphite heating rods offer a glimpse into the future of heating systems.

Rib Features of Injection Molded Parts: A Guide for Plastic Manufacturing

Injection Molded Part Ribs: Credible Plastic Mold and Injection Molding Manufacturer Now Offers Quality ProductsIn response to increasing demand for industrial and household injection molded parts, our company, a leading China-based plastic mold and injection molding manufacturer, has launched a new range of high-quality injection molded part ribs. With our industry experience spanning over 20 years, we have achieved remarkable success in delivering innovative, durable, and affordable injection molded parts to our clients in various industries including automotive, medical, electronics, and consumer goods.We understand that a high-quality rib is crucial for the longevity and functionality of injection molded parts. Injection molded part ribs provide structure and support during the manufacturing process, giving the part strength, stiffness, and flexibility. We are aware that not all injection molded part ribs are equally effective. As a result, we employ the latest technology and top-grade materials during the manufacturing process to ensure that our injection molded part ribs are of the highest quality, providing unmatched reliability and longevity for your injection molded parts.Our company takes pride in providing unique, custom-made injection molded part ribs to meet clients’ specific needs. From the initial inquiry phase to the final delivery, we work closely with our clients to ensure that we deliver personalized solutions that exceed expectations. Our dedicated team of experts ensures that all the processes leading to the production of injection molded part ribs are carefully monitored, and all the necessary quality control measures are implemented.We recognize the increased need for cost-effective injection molded part ribs without compromising on quality. At our company, we offer our clients affordable injection molded part ribs that meet their budget requirements while still maintaining high quality. Our production process is streamlined, and we take advantage of economies of scale to lower the costs of production without sacrificing quality. In addition, our clients benefit from our flexible payment options tailored to suit their needs.Our reputation is anchored on the quality of the products we deliver, the attention paid to detail, and our commitment to excellent customer service. We ensure that our clients receive timely delivery of injection molded part ribs without delays or complications. Our line of injection molded part ribs is designed to cater to the changing needs of our clients across various industries.In conclusion, our company is a trusted and reliable partner that offers high-quality injection molded part ribs that meet industrial and household needs. Our manufacturing process is flexible, and we provide clients with personalized solutions that are custom-made to suit their unique needs. We offer affordable injection molded part ribs that meet the budget requirements of our clients without compromising on quality. We are committed to providing timely delivery of products, excellent customer service, and expert advice. Partner with us today and enjoy the benefits of high-quality injection molded part ribs that will enhance the longevity and functionality of your injection molded parts.

Digital Control Metal Melting Furnace with Graphite Crucible for DIY Projects

Electric Melting Furnace Forge Metal DIY Digital Control Graphite Crucible: A Must-Have for Metalworking EnthusiastsMetalworking enthusiasts always strive to create high-quality finished products that meet their exact specifications. However, achieving a perfect end product often requires the use of specialized tools and equipment. One such tool is an electric melting furnace forge metal DIY digital control graphite crucible. This device has revolutionized the metalworking industry by making it easier to melt and shape metals with precision and accuracy.The electric melting furnace forge metal DIY digital control graphite crucible is a powerful and versatile tool that can handle different types of metals, including precious metals such as gold, silver, and platinum. It is also perfect for melting other types of metals like copper, brass, and aluminum, making it an essential tool for metalworking enthusiasts and professionals alike.This advanced technology furnace is equipped with a digital control temperature system that allows users to set and maintain precise temperatures according to their specific metalworking requirements. The device's digital control system eliminates guesswork from the melting process, ensuring that your metal melts evenly and at a consistent temperature. This feature not only helps prevent wastage but also ensures a higher quality of work.The furnace's graphite crucible is another feature that sets it apart from traditional furnaces. Graphite is an excellent material for melting metals because it has high thermal conductivity, making it ideal for transferring heat efficiently. This ensures that the metal is melted evenly and efficiently, resulting in high-quality end products. Additionally, the graphite crucible is durable and resists chemical corrosion, making it last longer than traditional metal crucibles.This electric melting furnace forge metal DIY digital control graphite crucible is easy to install and use. The device is compact and portable, making it perfect for use at home, in the workshop, or on the go. Its digital control system is user-friendly, and its instructions are straightforward, making it easy to operate, even for beginners.Quality is at the forefront of the manufacturers' minds when producing this device. It is made with durable and high-quality materials to ensure longevity, efficiency, and performance. The manufacturers also offer a warranty that covers manufacturing defects, giving customers peace of mind when using the device.In conclusion, the electric melting furnace forge metal DIY digital control graphite crucible is a must-have tool for metalworking enthusiasts and professionals who want to produce high-quality end products. Its compact size, precise digital control system, and graphite crucible make it ideal for melting and shaping metals with precision and efficiency. The product's durability, longevity, and warranty ensure that you get value for your money. Purchase one today and take your metalworking skills to the next level.

Discover the Benefits of Isomolded Graphite for Various Applications

Creating a Stronger Future with Isomolded Graphite In today's rapidly evolving world, the demand for high-performance materials is constantly increasing. As industries strive for greater efficiency and sustainability, there is a growing need for innovative solutions that can withstand extreme conditions and deliver reliable performance. This is where isomolded graphite comes into play, offering a unique combination of strength, versatility, and reliability that is unmatched by other materials.Isomolded graphite is a highly engineered material that is specifically designed to meet the most demanding industrial applications. It is created through a process of carefully controlled molding and carbonization, resulting in a material that is incredibly strong, lightweight, and resistant to heat, corrosion, and wear. This makes it an ideal choice for a wide range of industries, including aerospace, automotive, electronics, and semiconductor manufacturing.One company that has been at the forefront of isomolded graphite innovation is {}. With a strong commitment to research and development, {} has continuously pushed the boundaries of what is possible with this remarkable material. Their expertise in advanced materials and manufacturing techniques has enabled them to produce isomolded graphite products that are second to none in terms of quality and performance.{} offers a diverse range of isomolded graphite products, including crucibles, molds, dies, and heating elements, all of which are designed to withstand the harshest operating conditions and deliver exceptional performance. Whether it's in the production of high-purity metals, the casting of complex components, or the handling of molten materials, {}'s isomolded graphite products have proven to be indispensable in achieving superior results.One of the key advantages of {}'s isomolded graphite products is their ability to deliver consistent performance over a wide range of operating temperatures. This makes them an ideal choice for applications where thermal stability is critical, such as in high-temperature furnaces, chemical processing equipment, and semiconductor manufacturing processes. With {}'s isomolded graphite products, customers can have the confidence that their operations will run smoothly and efficiently, without the risk of material failure or degradation.In addition to their exceptional physical properties, {}'s isomolded graphite products are also known for their precise dimensional accuracy and exceptional surface finish. This makes them well-suited for applications where tight tolerances and smooth surfaces are essential, such as in the production of precision components for the aerospace and defense industries. By offering products that meet the most stringent quality standards, {} has earned a reputation as a trusted partner for companies looking to achieve the highest levels of performance and reliability.Moreover, {} is committed to sustainability and environmental responsibility in their production processes. They prioritize using eco-friendly materials and minimizing their carbon footprint, ensuring that their isomolded graphite products not only perform exceptionally but also contribute to a greener, more sustainable future. As industries continue to prioritize sustainability and environmental stewardship, {}'s dedication to producing eco-friendly isomolded graphite products will undoubtedly make them an attractive choice for customers looking to reduce their environmental impact.Looking ahead, the future for isomolded graphite looks promising, especially with the continued dedication and innovation of companies like {}. As industries continue to push the boundaries of what is possible, the demand for strong, versatile, and reliable materials will only grow, making isomolded graphite an essential component in shaping a stronger and more sustainable future.In conclusion, isomolded graphite stands as a testament to the incredible potential of advanced materials in driving innovation and progress across a wide range of industries. With its exceptional strength, versatility, and reliability, isomolded graphite is poised to play a crucial role in meeting the evolving needs of industry and society. As companies like {} continue to push the boundaries of what is possible with this remarkable material, the future for isomolded graphite looks brighter than ever.

Circular and Rectangular Graphite Crucibles for Rare-Earth Metallurgy and Chemical Industries

Graphite Crucibles: A Reliable Choice for Metallurgy and Chemical IndustriesGraphite crucibles are widely used in metallurgy and chemical industries for various reasons. They are known for their high-temperature resistance, good thermal conductivity, and corrosion resistance, making them ideal for applications that require extreme temperatures and harsh chemical environments. Graphite crucibles come in various shapes and sizes depending on their intended use, with circular and rectangular types being the most commonly used.Rare-earth MetallurgyIn rare-earth metallurgy, graphite crucibles are used for melting, casting, and smelting rare-earth metals due to their high-temperature resistance. Rare-earth metals are used in many industries, including aerospace, electronics, and medical devices. The demand for rare-earth metals has been on the rise in recent years, making their extraction, processing, and production more critical than ever.Graphite crucibles offer an ideal solution for the high-temperature requirements of rare-earth metallurgy, as regular crucibles would not be able to withstand the extreme temperatures required in the melting process. Graphite crucibles can withstand temperatures of up to 3000°C, making them perfect for melting difficult-to-process rare-earth metals such as neodymium, dysprosium, and europium.Load Plates for Anodes of Tantalum Electrolyzing CapacitorsGraphite crucibles are also used as load plates for the anodes of tantalum electrolyzing capacitors. Tantalum capacitors are an essential component in many electronic devices, including mobile phones, computers, and digital cameras. Graphite crucibles are used in the production of tantalum capacitors, in which they act as load plates, ensuring high-quality and reliable performance for the device.The use of graphite crucibles in the production of tantalum capacitors is due to their excellent electrical conductivity and resistance to chemical corrosion. Graphite also has high heat resistance, which ensures the capacitors can maintain performance even under extreme temperatures. Additionally, graphite is lightweight, making it easier to handle and transport in the production process.Corrosion Resistance in Chemical IndustriesIn chemical industries, graphite crucibles are commonly used due to their excellent resistance to chemical corrosion. Graphite crucibles are used in the manufacture of a wide range of chemical products, including acids, fertilizers, industrial chemicals, and pharmaceuticals, among others.The use of graphite crucibles in the chemical industry is due to their excellent chemical resistance, preventing chemical reactions between the crucible and the chemicals being processed. Additionally, graphite is compatible with various chemicals, ensuring no contamination occurs during the production process.ConclusionGraphite crucibles offer a reliable solution for various industries, from rare-earth metallurgy to chemical industries. The unique qualities of graphite, such as high-temperature resistance, good thermal conductivity, and corrosion resistance, make it an ideal choice for applications that require extreme temperatures and harsh chemical environments.With the increasing demand for rare-earth metals and electronic devices, the use of graphite crucibles will continue to play a significant role in the production of these products. Furthermore, the chemical industry will rely on graphite crucibles to ensure the production of high-quality chemical products. The use of graphite crucibles represents an investment in quality since it will help in producing high-quality products, ensuring customer satisfaction.About the company:name removed has been a leading supplier of quality graphite products for over 20 years. With extensive experience and expertise in the industry, they offer a wide range of graphite products, including crucibles, rods, plates, and blocks for various industrial applications. By maintaining high-quality standards and providing excellent customer service, name removed has become a trusted name in the graphite industry.

Discover the Properties and Uses of Graphite - A Soft, Conductive Form of Carbon

Graphite Blank: The Ultimate Tool for High-Quality Drawings and SketchesIf you are someone who loves art, you would know how crucial it is to have the right tools to create beautiful pieces. And when it comes to creating detailed drawings and sketches, one material that comes to mind is graphite.Graphite is a form of carbon that is widely known for its soft, black, and lustrous texture. It has excellent electrical conductivity, making it ideal for use in electronics. However, its most common use is as a tool for artists and designers.The use of graphite dates back to the 16th century, when it was first used as a writing and drawing instrument. Today, it is widely used for making high-quality drawings, sketches, and illustrations, making it an essential tool for artists and designers worldwide.One of the most popular forms of graphite is the graphite blank. A graphite blank is a rod-shaped piece of graphite that is typically used to make lead pencils. However, it is also used for other purposes, such as in lubricants, electrolytic anodes, and even as a moderator in nuclear reactors.When it comes to creating drawings and sketches, the graphite blank is the preferred tool of many artists. One of the reasons for this is its versatility. Graphite blanks come in different grades, making them suitable for different types of drawings.The H-grade graphite blank, for instance, is slightly hard and produces light lines, making it ideal for shading and adding texture to your drawings. The B-grade graphite blank, on the other hand, is softer and produces darker lines, making it ideal for creating bold and dark strokes.Moreover, graphite blanks are also durable and long-lasting, making them an excellent investment for artists who want to create high-quality artworks. They are also convenient to use, as you can easily sharpen them to create finer or thicker lines, depending on your needs.In conclusion, the graphite blank is an essential tool for any artist who wants to create high-quality drawings and sketches. Its versatility, durability, and convenience make it the go-to option for professionals and beginners alike. So, if you are an artist looking to create beautiful artworks, getting a graphite blank is an investment you won't regret.