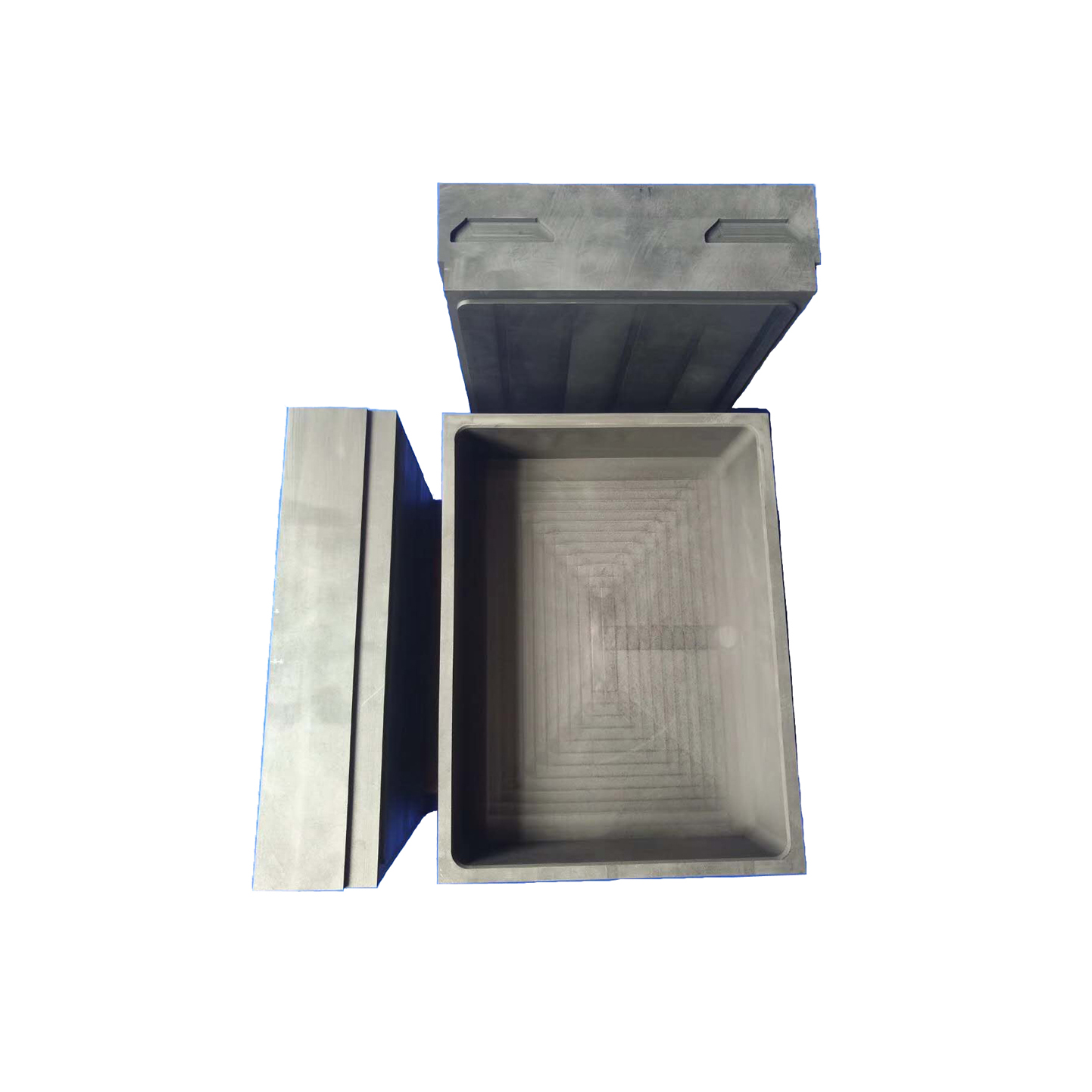

High-quality 10 Kg Graphite Crucible for Metal Casting and Melting Applications

By:Admin

The 10 Kg Graphite Crucible is designed for use in high-temperature applications such as melting and refining metals, as well as in the production of various chemical compounds. Made from premium quality graphite, the crucible offers excellent thermal stability and resistance to thermal shock, making it an ideal choice for demanding industrial processes.

With a capacity of 10 Kg, the crucible is suitable for small to medium-scale operations, providing customers with a versatile and reliable solution for their manufacturing needs. Its durable construction and exceptional heat retention properties ensure consistent performance and long-lasting durability, making it a cost-effective investment for businesses looking to optimize their production processes.

In addition to its superior technical characteristics, the 10 Kg Graphite Crucible is also designed with user convenience in mind. Its lightweight construction and easy handling make it simple to transport and install, while its smooth interior surface facilitates quick and efficient cleaning and maintenance.

As a company with a long-standing reputation for delivering top-notch products and exceptional customer service, {} is dedicated to ensuring that its customers receive the best value for their investment. The launch of the 10 Kg Graphite Crucible is a testament to the company's commitment to innovation and continuous improvement, as it continues to strive towards meeting the evolving needs of the industry.

{} has a proven track record of providing high-quality industrial materials to a wide range of customers, including those in the metal casting, foundry, and manufacturing sectors. With a strong focus on research and development, the company consistently invests in cutting-edge technologies and processes to ensure that its products meet the highest standards of quality and performance.

Furthermore, {} is known for its comprehensive customer support and technical expertise, offering clients tailored solutions to suit their specific requirements. Whether it's providing detailed product information, offering advice on material selection, or assisting with troubleshooting, the company's team of experts is always on hand to deliver personalized assistance and guidance.

The launch of the 10 Kg Graphite Crucible is yet another example of {}'s unwavering dedication to meeting the needs of its customers and driving forward the industry with innovative solutions. With a focus on quality, performance, and reliability, the company continues to set the benchmark for excellence in industrial materials, cementing its position as a trusted partner for businesses around the world.

In conclusion, the introduction of the 10 Kg Graphite Crucible by {} represents a significant advancement in the field of industrial materials. With its superior technical characteristics, user-friendly design, and unwavering commitment to customer satisfaction, the crucible is set to make a lasting impact in the market and further solidify {}'s position as a leader in the industry.

Company News & Blog

Innovative Graphite Box Enables Efficient Storage of Carbonized Powder

LONDON, UK - Graphite boxes have long been considered as one of the best choices for carbonized powder packaging, as they offer a high level of durability and protection. The increasing demand for carbonized powder, coupled with the need for safe and secure packaging, has led to a surge in the development and production of graphite boxes. One such manufacturer is a company that specializes in the production of high-quality graphite products for industrial use.This company has recently launched its latest product, a graphite box designed specifically for carbonized powder. This new offering promises to provide customers with a high-quality packaging solution that ensures maximum protection for their powdered products.The graphite box is made from premium-quality graphite, which is known for its high strength and durability. This ensures that the box can withstand the rigors of transportation and storage without compromising the quality of the product inside. Additionally, the box has been designed to be airtight, which prevents the powder from getting contaminated by external elements.Speaking about the new product, the company's spokesperson said, "We are thrilled to introduce our latest offering to the market. This graphite box is the culmination of years of research and development aimed at providing our customers with the best possible packaging solution for their carbonized powder. We are confident that this product will meet and exceed the expectations of our customers."The spokesperson also spoke about the company's commitment to sustainability, saying, "We take our role as a responsible manufacturer very seriously. That's why we use only eco-friendly materials in our production processes. By doing so, we help reduce our environmental impact while offering our customers high-quality products that meet their needs."The company, which has been in the graphite manufacturing industry for over a decade, has earned a reputation for providing high-quality, innovative products to its customers. Its portfolio of products includes a range of graphite products such as crucibles, molds, and electrodes, which are used in various industrial applications.The launch of this new product is expected to further strengthen the company's position in the market. With the demand for carbonized powder set to rise in the coming years, the company is well-positioned to capitalize on this growth by providing its customers with a reliable, high-quality packaging solution.In conclusion, the launch of the graphite box for carbonized powder by this company is a significant development that underscores its commitment to providing innovative and sustainable solutions to its customers. With this product, the company has set a new standard in the packaging industry and is poised to continue leading the way in graphite manufacturing for years to come.

Durable High Density Isomolded Graphite Rod with Accurate Diameter Tolerance

Graphite is a unique material known for its high strength, high density, and remarkable wear resistance. One of the most popular applications of graphite is in the manufacturing of heating rods. Graphite heating rods are widely used in various industries such as chemical, metallurgical, and mechanical. It is a preferred material due to its excellent thermal and electrical conductivity as well as its durability. If you have never heard of graphite heating rods, here is what you need to know.Graphite heating rods are essentially graphite rods that have been designed to conduct heat. They are used in industrial processes that require high-temperature environments, and they are incredibly efficient at their job. Graphite heating rods are especially useful in applications where other materials, such as metals, would fail due to high-temperature conditions. Unlike metal heating rods, graphite heating rods can withstand high temperatures for extended periods without losing their strength or structural integrity.One of the most notable features of graphite heating rods is their extraordinary thermal conductivity. Graphite is an excellent conductor of heat, much better than most other materials. Its interlocking hexagonal structure allows it to conduct heat efficiently, making it an ideal material for heat transfer applications. Graphite heating rods can transfer heat effectively, which makes them an essential component in various industrial processes.Another notable feature of graphite heating rods is their electrical conductivity. Graphite is a highly conductive material that exhibits excellent electrical conductivity, which makes it an excellent choice for manufacturing heating rods. Graphite heating rods are used in applications that require both thermal and electrical conductivity, such as electroplating, anodizing, and furnace heating.Graphite heating rods are also known for their excellent wear resistance. Due to their strong carbon bonds, graphite heating rods can withstand abrasion and wear. They can endure harsh conditions such as high temperatures, corrosive chemicals, and mechanical forces without deteriorating or losing their structural integrity. Graphite heating rods are an ideal choice for applications where wear and tear are common.In conclusion, graphite heating rods are an incredible material used in various industrial processes that require high-temperature environments. They exhibit excellent thermal and electrical conductivity, wear resistance, and strength. They are more efficient than metal heating rods and can transfer heat effectively, which makes them an ideal choice for various applications. If you are looking for a heating rod that can withstand harsh and high-temperature conditions, graphite heating rods are the way to go.

Newly Released Graphite Box Enhances Storage and Transportation of Anode Powder

Graphite Box For Anode Powder Revolutionizes the Battery IndustrySeptember 15, 2022In a groundbreaking move that promises to revolutionize the battery industry, a leading global manufacturer has introduced an innovative product - the Graphite Box for Anode Powder. This cutting-edge solution offers a range of benefits that are set to transform the way batteries are produced, used, and recycled. With its exceptional performance, versatility, and sustainable features, this revolutionary product is set to disrupt the industry status quo.The Graphite Box for Anode Powder is a game-changer when it comes to battery manufacturing. Designed by an industry-leading company known for their commitment to innovation, quality, and sustainability, this ground-breaking product is set to enhance the performance and longevity of batteries across various industries.One of the key advantages of the Graphite Box lies in its exceptional ability to provide stability and consistency in anode powder production. The graphite material is known for its excellent thermal conductivity, which allows for efficient heat dissipation during the battery manufacturing process. This results in superior quality anode powder with optimized electrochemical properties.Furthermore, the Graphite Box boasts outstanding durability, ensuring it can withstand extreme temperature variations and chemical interactions, thereby extending its lifecycle and reducing the frequency of replacements. This not only results in significant cost savings for battery manufacturers but also reduces the environmental impact associated with frequent replacements.To ensure the highest standards of sustainability, the Graphite Box is crafted using eco-friendly materials. By reducing the reliance on non-renewable resources and maximizing energy efficiency, it promotes a greener approach to battery manufacturing. This aligns with the global push towards a more sustainable future and positions the Graphite Box as a frontrunner in supporting environmental conservation efforts.The versatility of the Graphite Box sets it apart from traditional alternatives. It can be used across a wide range of battery types, from lithium-ion batteries in electric vehicles and portable electronics to energy storage systems for renewable sources. This adaptability not only simplifies the manufacturing process but also streamlines the supply chain, making it more efficient and cost-effective.Moreover, the Graphite Box's innovative design allows for easy integration into existing production lines, ensuring a seamless transition for manufacturers. The compatibility and flexibility of this product enable battery manufacturers to optimize their operations without significant disruptions, fostering quicker adoption and industry-wide acceptance.The Graphite Box's impact extends beyond the manufacturing stage. As increasing emphasis is placed on battery recycling to minimize waste, this revolutionary product stands out due to its recyclability. The graphite material is easily separable from other battery components, simplifying the recycling process and minimizing resource wastage. This marks a significant advancement in the circular economy model and reduces the environmental footprint associated with battery disposal.The introduction of the Graphite Box for Anode Powder marks a major milestone in the battery industry, offering unmatched performance, sustainability, and versatility. As the world continues to prioritize renewable energy and electric mobility, this innovative solution presents manufacturers with a powerful tool to meet the surging demand for high-quality, sustainable batteries. With its potential to reduce costs, improve battery performance, and contribute to a cleaner planet, the Graphite Box is set to reshape the industry landscape and unlock a new era of battery technology.About the Company:The company behind the Graphite Box for Anode Powder is a global leader in advanced materials and technology solutions for various industries. With a strong focus on research and development, innovation, and sustainability, they are dedicated to delivering cutting-edge products that surpass customer expectations. With a robust global presence and an unwavering commitment to quality, this company continues to shape the future of industries around the world.

High-Quality Graphite Boats on the Rise in China

China-based graphite boat manufacturer, XX Company, has recently introduced a new range of high-quality graphite boats to its product portfolio. The new boats are designed for use in high-temperature applications such as the manufacturing of semiconductor materials and solar silicon wafers.Graphite boats are a key component in various heat-treating applications, particularly in the semiconductor and solar industries. They are used to hold and transport small pieces of semiconducting or solar wafers through the high-temperature furnace. The high-quality graphite material used in these boats provides excellent thermal conductivity, chemical resistance, and thermal shock resistance, making it perfect for high-temperature applications.With over 10 years of experience in manufacturing high-quality graphite products, XX Company has established itself as one of the leading suppliers of graphite boats in China. The company has a strong presence in the domestic market and has also been exporting its products to various countries around the world, including South Korea, Japan, and the United States.The company has invested heavily in research and development to improve the quality of its graphite products. The new range of boats is a testament to the company's commitment to providing its customers with high-quality, reliable products. The boats are made using high-purity graphite, which ensures a uniform and consistent structure, resulting in superior thermal conductivity and chemical resistance.Additionally, the company uses advanced manufacturing techniques to produce boats with precise dimensions and tolerances, ensuring they fit perfectly into the high-temperature furnaces and can transport the delicate semiconductor and solar wafers without any damage.One of the key advantages of XX Company's graphite boats is their long service life. Typically, graphite boats have a life span of around 50-100 uses, depending on the specific application and operating conditions. However, XX Company's boats are designed to last up to 150 uses, which translates into significant cost savings for its customers.The company's dedication to quality and reliability has earned it a reputation as a trusted supplier of graphite boats in the industry. The company has a stringent quality control process in place to ensure that its products meet the highest standards. Each boat undergoes rigorous testing and inspection before being shipped to customers, guaranteeing that it performs as expected in the high-temperature furnace.In addition to its standard product range, XX Company also offers custom-made graphite boats to suit specific customer requirements. The company's engineering team works closely with customers to understand their unique needs and creates bespoke solutions that meet their exact specifications.With a comprehensive product range, excellent quality, and reliable performance, XX Company is well-positioned to be a major player in the global graphite boat market. The company's commitment to innovation and quality has enabled it to establish a strong foothold in the industry and will continue to drive its growth in the years to come.

Durable Graphite Casting Moulds for Pearl Jewelry and Crafts

Graphite Coin Mould: The Perfect Solution for Your Casting NeedsCasting has been an integral part of industries for centuries, and with the advancement of technology, the process has become even more refined. One of the crucial elements in casting is the mold used to shape the molten metal. Graphite molds have gained popularity due to their unique properties and versatility. Graphite Coin Mould, a leading manufacturer of graphite molds, offers state-of-the-art solutions to meet your casting needs.Graphite molds have a high resistance to heat and are durable to withstand the high temperatures in the casting process. This property makes them ideal for casting metals such as iron, steel, and various non-ferrous metals. Graphite Coin Mould offers a wide range of high-quality graphite molds, including those used in coin production, jewelry making, and arts & crafts.Coin production requires a high level of accuracy and precision in the casting process to meet the standards set by regulatory bodies. Graphite Coin Mould’s graphite coin molds provide the perfect solution to achieve this level of precision. The molds are made with high-purity graphite, ensuring a smooth and consistent surface finish on the coins. They have a long lifespan and can withstand thousands of casting cycles, making them a cost-effective solution in the long run.Jewelry making is an art that requires the use of molds to create intricate designs. Graphite Coin Mould’s graphite jewelry molds are specially designed to meet the needs of jewelry makers. The molds come in various shapes and sizes, and their unique properties allow for the creation of precise and intricate designs. Graphite molds are also non-stick, which makes them easy to clean and maintain, reducing the time needed to clean the molds.Arts & crafts is an industry that has benefited greatly from graphite molds. The molds are used to create sculptures, decorative items, and ornaments, among other things. Graphite Coin Mould’s graphite molds provide the perfect solution for creating unique and beautiful designs. Their high-quality molds are durable, easy to use, and provide consistent results, making them the perfect choice for any artist.Besides the standard molds used in coin production, jewelry making, and arts & crafts, Graphite Coin Mould offers customized molds to meet specific customer needs. The company takes pride in its ability to work with clients in the creation of unique molds for their casting needs. Their team of experts combines years of experience with the latest technology to deliver customized solutions to meet the needs of their clients.In conclusion, Graphite Coin Mould’s graphite molds provide the perfect solution for casting needs. Their high-quality molds are durable, easy to use, and provide consistent results. The molds are used in various industries, including coin production, jewelry making, and arts & crafts. The company’s ability to provide custom solutions sets them apart from their competitors. Graphite Coin Mould is committed to providing the highest quality molds and exceptional service to their clients.

High-Quality Graphite Moulds for Industrial Applications

Graphite Moulds, also known as graphite molds, are an essential tool in the manufacturing industry. They are used in the production of a wide range of products, including metal parts, glass products, and even certain types of jewelry. These molds are highly durable and can withstand extreme temperatures, making them ideal for use in various industrial applications.One company that has established itself as a leader in the production of graphite molds is {Company Name}. With a strong focus on quality and innovation, {Company Name} has built a reputation for delivering top-of-the-line products that meet the needs of its diverse customer base.Established in 1998, {Company Name} has grown from a small workshop to a globally recognized manufacturer of graphite products. The company's state-of-the-art production facilities, along with its team of experienced engineers and technicians, enable it to produce high-quality graphite molds that are tailored to meet the specific requirements of its clients.One of the key advantages of using graphite molds is their ability to withstand high temperatures without deforming or cracking. This makes them ideal for use in processes such as die casting, where molten metal is poured into the molds to create intricate shapes and designs. The superior heat resistance of graphite molds ensures that they can withstand the extreme temperatures involved in this process, resulting in a high-quality finished product.In addition to their heat resistance, graphite molds also offer excellent dimensional stability, ensuring that the products manufactured using these molds are consistently accurate and precise. This is crucial in industries such as aerospace, automotive, and electronics, where tight tolerances and exact specifications are of the utmost importance.{Company Name} understands the critical role that graphite molds play in modern manufacturing processes, and as such, it is committed to producing molds that consistently meet the highest standards of quality and performance. The company takes a proactive approach to research and development, continuously seeking out new techniques and technologies to enhance the capabilities of its graphite molds. This dedication to innovation has allowed {Company Name} to stay ahead of the curve and deliver innovative solutions that address the evolving needs of its customers.Furthermore, {Company Name} is dedicated to providing exceptional customer service, working closely with clients to understand their unique requirements and deliver customized solutions that meet their specific needs. Whether it's a complex molding project or a high-volume production run, {Company Name} prides itself on its ability to deliver reliable, high-quality graphite molds that exceed expectations.In conclusion, graphite molds are a vital component in the manufacturing industry, and {Company Name} stands out as a leading producer of these essential tools. With a steadfast commitment to quality, innovation, and customer satisfaction, {Company Name} continues to set the standard for excellence in the production of graphite molds. As the manufacturing industry continues to evolve, {Company Name} remains at the forefront, providing cutting-edge solutions that meet the diverse needs of its global customer base.

Innovative Porous Coating Graphite Mould: A New Advancement in Mould Technology

Porous Coating Graphite Mould has become an essential tool in the manufacturing industry, revolutionizing the way manufacturers create complex and intricate metal parts. The innovative technology behind Porous Coating Graphite Mould is making waves in the industry, providing manufacturers with a cost-effective and efficient solution for producing high-quality metal parts.With a history of over 20 years in the industry, {Company Name} has established itself as a leader in the production and distribution of Porous Coating Graphite Mould. The company has a strong focus on research and development, constantly striving to improve its products and stay ahead of the curve in terms of technological advancements. This commitment to innovation has allowed {Company Name} to become a trusted partner for manufacturers looking to improve their production processes.Porous Coating Graphite Mould is a versatile tool that can be used in a wide range of manufacturing applications. Whether it's producing automotive parts, aerospace components, or medical devices, Porous Coating Graphite Mould offers manufacturers the flexibility and precision they need to meet their production demands. The technology works by allowing gas to pass through the mould, which results in a uniform and consistent coating on the metal part being produced. This ensures that the final product has a smooth and flawless surface finish, free from imperfections or defects.One of the key advantages of using Porous Coating Graphite Mould is its ability to produce complex and intricate metal parts with high precision. This is particularly important in industries such as aerospace and medical manufacturing, where the smallest flaw in a part can have serious consequences. By using Porous Coating Graphite Mould, manufacturers can ensure that their parts meet the highest quality standards, while also reducing production time and costs.In addition to its precision and versatility, Porous Coating Graphite Mould also offers cost savings for manufacturers. The technology allows for a more efficient use of materials, reducing waste and minimizing the need for additional finishing processes. This results in lower production costs and a more sustainable manufacturing process overall.{Company Name} is committed to providing its customers with the highest quality Porous Coating Graphite Mould, backed by exceptional customer service and support. The company works closely with its clients to understand their specific production needs and develop customized solutions to meet those requirements. With a team of experienced engineers and technical experts, {Company Name} is able to provide comprehensive support to its customers, from initial consultation to ongoing maintenance and support.As the manufacturing industry continues to evolve and demand for high-quality metal parts grows, Porous Coating Graphite Mould is set to play a crucial role in shaping the future of manufacturing. With its precision, versatility, and cost-saving benefits, this innovative technology is helping manufacturers stay ahead of the curve and meet the ever-increasing demands of their customers. And with {Company Name} at the forefront of this technological revolution, manufacturers can trust that they have a reliable partner to support their production needs.

High-quality 10 Kg Graphite Crucible for Metal Casting and Melting Applications

Recently, a well-known company in the industrial materials industry has announced the launch of its newest product, the 10 Kg Graphite Crucible. With a focus on providing high-quality and innovative products to its customers, the company has once again solidified its position as a leader in the industry.The 10 Kg Graphite Crucible is designed for use in high-temperature applications such as melting and refining metals, as well as in the production of various chemical compounds. Made from premium quality graphite, the crucible offers excellent thermal stability and resistance to thermal shock, making it an ideal choice for demanding industrial processes.With a capacity of 10 Kg, the crucible is suitable for small to medium-scale operations, providing customers with a versatile and reliable solution for their manufacturing needs. Its durable construction and exceptional heat retention properties ensure consistent performance and long-lasting durability, making it a cost-effective investment for businesses looking to optimize their production processes.In addition to its superior technical characteristics, the 10 Kg Graphite Crucible is also designed with user convenience in mind. Its lightweight construction and easy handling make it simple to transport and install, while its smooth interior surface facilitates quick and efficient cleaning and maintenance.As a company with a long-standing reputation for delivering top-notch products and exceptional customer service, {} is dedicated to ensuring that its customers receive the best value for their investment. The launch of the 10 Kg Graphite Crucible is a testament to the company's commitment to innovation and continuous improvement, as it continues to strive towards meeting the evolving needs of the industry.{} has a proven track record of providing high-quality industrial materials to a wide range of customers, including those in the metal casting, foundry, and manufacturing sectors. With a strong focus on research and development, the company consistently invests in cutting-edge technologies and processes to ensure that its products meet the highest standards of quality and performance.Furthermore, {} is known for its comprehensive customer support and technical expertise, offering clients tailored solutions to suit their specific requirements. Whether it's providing detailed product information, offering advice on material selection, or assisting with troubleshooting, the company's team of experts is always on hand to deliver personalized assistance and guidance.The launch of the 10 Kg Graphite Crucible is yet another example of {}'s unwavering dedication to meeting the needs of its customers and driving forward the industry with innovative solutions. With a focus on quality, performance, and reliability, the company continues to set the benchmark for excellence in industrial materials, cementing its position as a trusted partner for businesses around the world.In conclusion, the introduction of the 10 Kg Graphite Crucible by {} represents a significant advancement in the field of industrial materials. With its superior technical characteristics, user-friendly design, and unwavering commitment to customer satisfaction, the crucible is set to make a lasting impact in the market and further solidify {}'s position as a leader in the industry.

How to Make Graphite Crucible: A Step-by-Step Guide

The demand for graphite crucibles is increasing in various industries such as metallurgy, jewelry making, and laboratory applications. Graphite crucibles are essential for the melting and refining of metals and alloys, as they can withstand high temperatures and are resistant to chemical erosion. To meet this growing demand, {Company Name} is expanding its production capacity and introducing innovative technologies to manufacture high-quality graphite crucibles.As a leading manufacturer of graphite products, {Company Name} has been providing reliable solutions for the metal casting and smelting industry for over a decade. The company has built a strong reputation for its commitment to quality, precision engineering, and exceptional customer service. With a state-of-the-art manufacturing facility and a team of experienced professionals, {Company Name} is well-positioned to deliver superior graphite crucibles that meet the exact requirements of its customers.The process of making graphite crucibles involves several intricate steps that require precision and expertise. First, the raw materials, including high-quality graphite powders and binders, are carefully selected and mixed in precise proportions to form a homogenous mixture. This mixture is then compacted and molded into the desired shape using advanced molding techniques. The formed crucibles are then subjected to a high-temperature baking process to carbonize the binder and enhance the strength and density of the crucible.In addition to traditional manufacturing methods, {Company Name} is leveraging advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining to enhance the quality and precision of its graphite crucibles. These technologies enable the company to produce crucibles with intricate designs and tight tolerances, ensuring consistent performance and reliability in demanding applications.With a strong focus on research and development, {Company Name} is constantly exploring new materials and manufacturing processes to further improve the performance of its graphite crucibles. The company has established collaboration with leading research institutions and industry experts to stay at the forefront of innovation and address the evolving needs of its customers. This proactive approach has enabled {Company Name} to introduce advanced graphite crucibles that offer exceptional thermal stability, resistance to thermal shock, and prolonged service life.In response to the increasing demand for graphite crucibles, {Company Name} is expanding its production capacity and optimizing its manufacturing processes to ensure timely delivery and cost-effective solutions for its customers. The company is also investing in training and skill development programs to empower its workforce with the knowledge and expertise required to produce high-quality graphite crucibles consistently.The graphite crucibles manufactured by {Company Name} are widely used in various applications, including the melting and casting of precious metals such as gold, silver, and platinum in jewelry making and refining processes. They are also utilized in the production of high-performance alloys and the analysis of metals in laboratory settings. {Company Name} offers a wide range of graphite crucibles in different sizes and configurations to cater to the diverse needs of its customers.In conclusion, {Company Name} is dedicated to meeting the growing demand for graphite crucibles by leveraging its expertise, advanced technologies, and commitment to quality. The company's ongoing investment in research and development, manufacturing capabilities, and customer-centric approach positions it as a trusted partner for industries that rely on high-performance graphite crucibles. With a focus on innovation and continuous improvement, {Company Name} is poised to drive further advancements in graphite crucible technology and contribute to the success of its customers.

Innovative Graphite Technology Revolutionizes Sintering Mould for Industry Applications

Graphite Sintering Moulds Revolutionize Manufacturing Processes(Graphite Company Name), a leading innovator in the field of advanced materials and manufacturer of cutting-edge graphite products, has recently introduced a groundbreaking new product - Graphite Sintering Moulds. These molds are set to revolutionize manufacturing processes across various industries, providing enhanced durability, heat resistance, and improved production efficiency.(Graphite Company Name) has been at the forefront of graphite-based innovations for over a decade, catering to the needs of industries such as automotive, aerospace, electronics, and more. With a dedicated research and development team, their focus has always been on developing advanced materials that push the boundaries of what is possible.The recently launched Graphite Sintering Moulds are the latest addition to (Graphite Company Name)'s extensive product portfolio. Traditionally, manufacturing processes involving high temperatures and pressure require molds that can withstand these extreme conditions. This is where Graphite Sintering Moulds come into play.One of the key advantages of these molds is their exceptional durability. Graphite, already known for its strength and resilience, has been further optimized in the development of these molds to withstand extreme heat conditions. This means that manufacturers can now produce high-quality, complex components without having to constantly worry about mold degradation due to high temperatures.Furthermore, the heat resistance of Graphite Sintering Moulds significantly reduces the cooling time required during the manufacturing process. The molds dissipate heat quickly and evenly, allowing for a rapid cooling process. This translates into increased production efficiency as manufacturers can achieve shorter cycle times, ultimately leading to higher productivity and reduced costs.In addition to their durability and heat resistance, these molds also offer excellent thermal conductivity. This unique property allows for more uniform heat distribution, resulting in consistent product quality and minimal defects. Manufacturers can rely on Graphite Sintering Moulds to deliver precise and reliable results, meeting the stringent requirements of various industries.Another notable advantage of Graphite Sintering Moulds is their versatility. These molds can be used in a wide range of manufacturing processes, including powder metallurgy, metal injection molding, and ceramic sintering. They have proven to be particularly effective in industries where the production of intricate and delicate components is required. The use of these molds enables precise replication of complex designs, ensuring consistent quality across batches.(Graphite Company Name)'s commitment to sustainability is also reflected in the development of these molds. Graphite is a naturally occurring mineral, and by utilizing it in manufacturing processes, the company minimizes the environmental impact associated with conventional mold materials. Additionally, the long lifespan of Graphite Sintering Moulds reduces the need for frequent replacements, further reducing waste generation.To cater to the diverse needs of their clients, (Graphite Company Name) offers customization options for their Graphite Sintering Moulds. The molds can be tailored to specific requirements, including sizes, shapes, and surface finishes. This flexibility allows manufacturers to optimize their production processes and achieve superior end-products.Overall, the introduction of Graphite Sintering Moulds represents a significant advancement in manufacturing technology. By providing exceptional durability, heat resistance, and thermal conductivity, these molds empower manufacturers to improve production efficiency and achieve consistent product quality. With their commitment to innovation and sustainability, (Graphite Company Name) continues to set new industry standards, driving progress and revolutionizing manufacturing processes across various sectors.