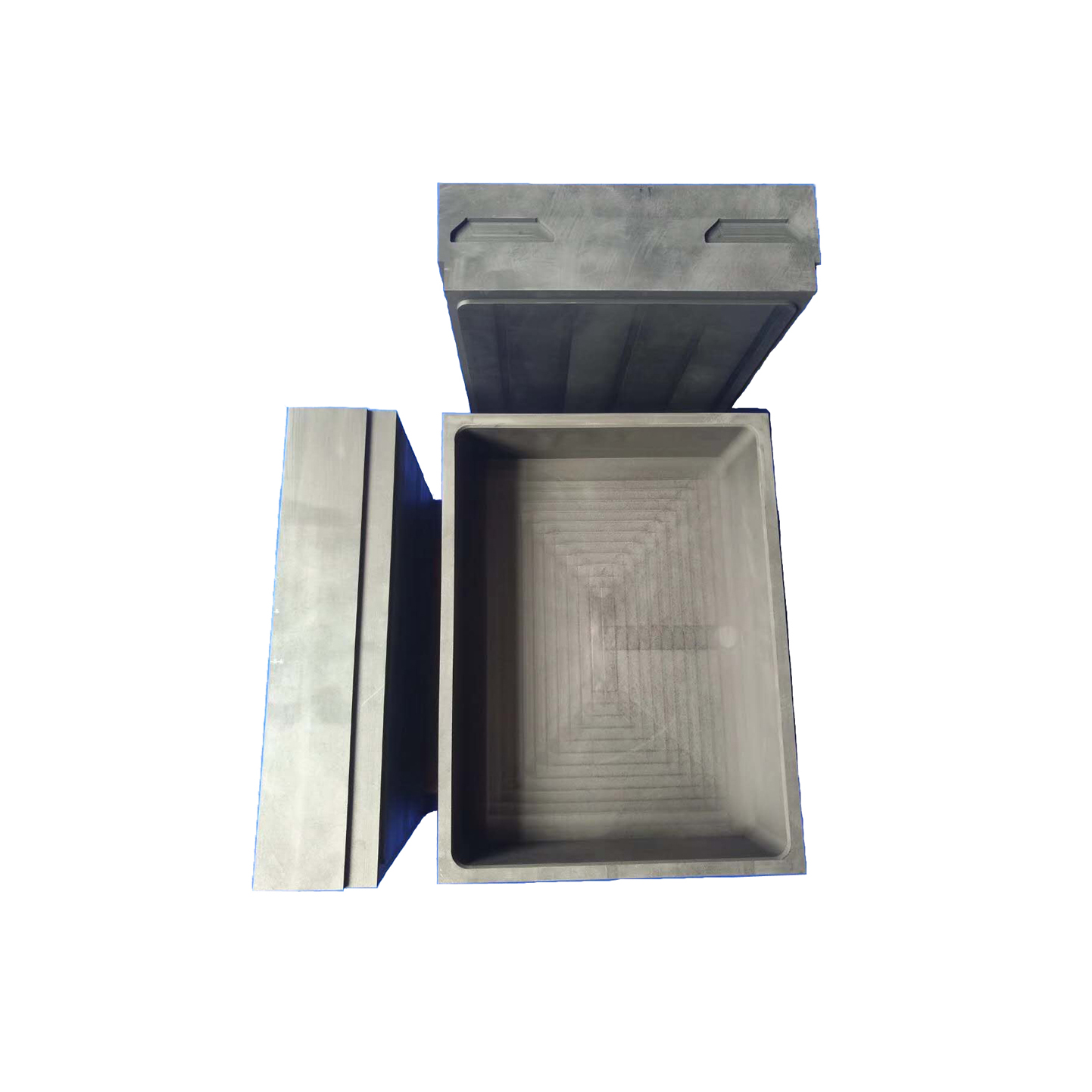

High Quality Carbon Graphite Calcination Crucible for Sale

By:Admin

The Carbon Graphite Calcination Crucible plays a crucial role in the process of calcination, which is a thermal treatment process used in various industries for the decomposition of materials at high temperatures. It is designed to withstand extreme temperatures and harsh chemical environments, making it an ideal choice for applications such as metal smelting, ore roasting, and ceramic production.

{Company Name} prides itself on the superior quality and performance of its Carbon Graphite Calcination Crucible. The crucible is manufactured using high-purity graphite materials and advanced production techniques to ensure excellent thermal conductivity, high temperature resistance, and minimal thermal expansion. This results in a reliable and cost-effective solution for customers' calcination processes.

In addition to its exceptional technical properties, the Carbon Graphite Calcination Crucible from {Company Name} is also known for its durability and long service life. This is achieved through meticulous quality control procedures and comprehensive testing methods employed by the company to guarantee the reliability and consistency of its products.

Furthermore, {Company Name} offers customization options for its Carbon Graphite Calcination Crucible to meet the specific requirements of different industries and applications. With a team of experienced engineers and technicians, the company can work closely with customers to develop tailored solutions that satisfy their unique calcination needs.

The Carbon Graphite Calcination Crucible is just one of the many high-quality carbon and graphite products offered by {Company Name}. The company's product range also includes graphite electrodes, graphite blocks, graphite powders, and various other graphite components. {Company Name} is committed to continuously expanding and improving its product offerings to serve the evolving needs of its customers across different industries.

With a strong focus on research and development, {Company Name} strives to stay at the forefront of carbon and graphite technology. The company invests in state-of-the-art equipment and facilities to enhance its manufacturing capabilities and develop new and innovative products. By leveraging its technical expertise and industry knowledge, {Company Name} aims to provide advanced carbon and graphite solutions that contribute to the success and competitiveness of its customers.

As a customer-centric company, {Company Name} places great emphasis on customer satisfaction and support. The company's dedicated sales and technical team is committed to providing professional and responsive services to customers worldwide. Whether it is product consultation, technical assistance, or after-sales support, {Company Name} is dedicated to delivering value and reliability to its customers at every step of the process.

In conclusion, the Carbon Graphite Calcination Crucible from {Company Name} offers exceptional quality, performance, and customization options for various calcination applications. With a strong focus on innovation, reliability, and customer satisfaction, {Company Name} continues to position itself as a trusted and preferred partner for carbon and graphite solutions in the global market.

Company News & Blog

High-Quality Graphite Block for Mold Applications: Properties and Uses

Mold Graphite Block: A Valuable Asset for Industrial ApplicationsGraphite has become an indispensable material in the industrial sector, finding extensive use in various applications such as mold making, metallurgy, and aerospace. Its unique properties, including high thermal and electrical conductivity, high melting point, and chemical inertness, make it an ideal choice for a wide range of industrial processes.One of the leading companies in the graphite industry, (company name), has recently introduced a new product to its lineup – Mold Graphite Block. This innovative offering is designed to cater to the specific needs of the mold making industry, providing superior performance and reliability.Mold graphite blocks are commonly used in the manufacturing of molds for the production of glass, metal, and plastic products. The high thermal conductivity and low coefficient of thermal expansion of graphite make it an excellent choice for mold materials, as it ensures uniform heat distribution and dimensional stability during the molding process.With the introduction of its Mold Graphite Block, (company name) aims to provide its customers with a high-quality, cost-effective solution for their mold making needs. The company's extensive experience and expertise in the graphite industry make it well-positioned to meet the growing demand for superior quality mold graphite blocks.In addition to its exceptional thermal properties, Mold Graphite Block offers excellent machinability, allowing for precision machining and shaping to meet the specific requirements of different mold designs. This flexibility and versatility make it a sought-after choice for mold makers looking to achieve high levels of accuracy and detail in their mold production.Furthermore, the chemical inertness of graphite ensures that Mold Graphite Block is highly resistant to corrosion and chemical attack, making it suitable for use in a variety of manufacturing environments. This durability and resistance to wear and tear contribute to the longevity and reliability of molds made from graphite blocks, ultimately leading to cost savings for manufacturers.As (company name) continues to expand its product offerings and technological capabilities, it remains committed to providing innovative solutions that meet the evolving needs of the industrial sector. The introduction of Mold Graphite Block is a testament to the company's dedication to delivering high-quality, high-performance materials to its customers.In the competitive landscape of the graphite industry, (company name) stands out as a trusted partner for businesses seeking reliable, long-lasting solutions for their industrial applications. With a strong focus on quality, innovation, and customer satisfaction, the company has earned a reputation as a leading provider of graphite products and services.As the demand for high-performance materials continues to grow across various industries, (company name) is well-positioned to meet these needs with its advanced product offerings and technical expertise. Mold Graphite Block is poised to make a significant impact in the mold making industry, offering a valuable asset for manufacturers looking to enhance the efficiency and quality of their production processes.With its exceptional thermal properties, machinability, and durability, Mold Graphite Block represents a new standard of excellence in mold making materials, setting (company name) apart as a trailblazer in the graphite industry. As the company continues to drive innovation and excellence, it is poised to shape the future of industrial applications with its cutting-edge solutions.

Densification Treatment of Graphite Crucible: A Comprehensive Guide

Densification Treatment Graphite Crucible Brings Innovation to the Metallurgy IndustryIn the world of metallurgy and metal casting, finding the right tools and equipment is crucial for success. With advancements in technology and materials, companies are constantly striving to improve their products to meet the demands of the industry. This is where the Densification Treatment Graphite Crucible comes in—a revolutionary product that is changing the game in the metallurgy industry.The Densification Treatment Graphite Crucible, developed by a leading company in the field of metallurgy equipment, has been designed to address the challenges faced by professionals in the industry. The crucible is made from high-quality graphite material, which has been subjected to a special densification treatment process to enhance its properties. This treatment process involves heating the graphite crucible to a high temperature under controlled conditions, which leads to the removal of impurities and the consolidation of the graphite structure. As a result, the crucible becomes more durable, thermally stable, and resistant to thermal shock—making it an ideal choice for various metallurgical applications.One of the key benefits of the Densification Treatment Graphite Crucible is its ability to withstand extreme temperatures, making it suitable for use in high-temperature applications such as metal melting and casting. This is particularly important in industries such as foundries, where the crucible is subjected to intense heat during the metal casting process. The improved thermal stability of the crucible not only prolongs its service life but also ensures consistent performance, leading to higher productivity and cost savings for businesses.Moreover, the densification treatment process also enhances the mechanical strength of the graphite crucible, making it more resistant to cracking and damage during use. This is a significant advantage for professionals in the metallurgy industry, as it reduces the frequency of crucible replacement and maintenance, resulting in greater efficiency and reliability in their operations. Additionally, the improved durability of the crucible contributes to a safer working environment, as the risk of crucible failure and accidents is significantly reduced.Aside from its superior thermal and mechanical properties, the Densification Treatment Graphite Crucible also offers excellent chemical resistance, ensuring its compatibility with a wide range of metals and alloys. This versatility makes it a valuable asset for professionals working with different types of materials, as they can rely on the crucible to deliver consistent performance and quality results across various applications. Furthermore, the crucible's resistance to chemical corrosion minimizes the risk of contamination in metal casting processes, maintaining the integrity of the final products.With its exceptional performance and reliability, the Densification Treatment Graphite Crucible has garnered positive feedback from professionals in the metallurgy industry. Many have reported significant improvements in their operations, including reduced downtime, enhanced product quality, and cost savings. As a result, the crucible has gained a reputation for being a game-changer in the industry, setting new standards for excellence and innovation in metallurgical equipment.In conclusion, the Densification Treatment Graphite Crucible represents a leap forward in the metallurgy industry, offering professionals a reliable and high-performance tool for their operations. Its advanced properties and durability make it a top choice for businesses looking to optimize their metal casting processes and achieve superior results. With its proven track record and positive impact on the industry, the crucible has cemented its position as a leading solution for the evolving needs of the metallurgy sector. As technology continues to advance, it is products like the Densification Treatment Graphite Crucible that will drive progress and innovation in the field of metallurgy and metal casting.

High-Quality Graphite Mould for Sintering Casting from Chinese Factory

China Factory Industrial Graphite Mould For Sintering CastingChina has long been known for its manufacturing capabilities, and the industrial graphite mould for sintering casting is a true testament to this. This specialized mould is essential for the production of various metal and alloy components, and China has proved to be a leader in its manufacturing and distribution.The industrial graphite moulds are widely used in the sintering casting process, which involves heating and compacting metal powders to produce solid metal parts. This process requires precision and high-quality moulds to ensure the final products meet the required specifications.The {Company Name} is a leading manufacturer of industrial graphite moulds for sintering casting in China. With years of experience and a commitment to excellence, they have established themselves as a trusted supplier in the industry. Their products are known for their durability, precision, and superior performance, making them the top choice for many manufacturers.The industrial graphite moulds produced by {Company Name} are made from high-quality graphite materials, which provide excellent thermal stability and resistance to high temperatures. This ensures that the moulds can withstand the rigorous conditions of the sintering casting process, allowing for consistent and high-quality production.In addition to their exceptional quality, {Company Name} also offers a wide range of industrial graphite moulds to meet the diverse needs of their customers. Whether it is for small-scale production or large-scale manufacturing, they have the expertise and capacity to fulfill the requirements of their clients.Furthermore, {Company Name} is committed to innovation and continuous improvement. They invest in research and development to stay ahead of the latest industry trends and technological advancements. This allows them to introduce new and improved products to the market, ensuring that their customers have access to the most advanced and efficient industrial graphite moulds.Moreover, the company has a strong focus on customer satisfaction. They work closely with their clients to understand their specific needs and provide customized solutions that meet their requirements. This customer-centric approach has earned them a loyal and satisfied customer base, further establishing their reputation as a reliable and trustworthy supplier.As China continues to play a pivotal role in the global manufacturing industry, the industrial graphite moulds for sintering casting from {Company Name} are an essential component in the production of metal and alloy components. With their exceptional quality, diverse product range, and commitment to innovation, {Company Name} has solidified its position as a leader in the industry.With the increasing demand for high-quality metal and alloy components, the industrial graphite moulds for sintering casting from {Company Name} are poised to play a crucial role in meeting these requirements. Their dedication to excellence and customer satisfaction sets them apart in the competitive market, making them the preferred choice for manufacturers across the globe.In conclusion, the industrial graphite moulds for sintering casting from {Company Name} are a testament to China's manufacturing prowess. Their exceptional quality, diverse product range, and customer-centric approach have solidified their position as a leader in the industry. As the demand for high-quality metal and alloy components continues to grow, {Company Name} is well-positioned to meet these requirements and contribute to the success of manufacturers worldwide.

Top-quality Isostatic Metal Casting Molds for High-performance EDM Graphite Marble Mold

High Performance EDM Graphite Marble Mold: A Boon for Isostatically Bearing Metal Casting MoldsMetal casting is one of the most widely used techniques employed for producing various metal products. It involves pouring molten metal into a mold and allowing it to solidify into the desired shape. However, this process is not as simple as it sounds. The metal has to be cast with precision to ensure that the final product meets the desired specifications. One way to ensure this is by using high-quality graphite molds. Graphite molds are extensively used in the metal casting industry due to their exceptional properties such as high thermal conductivity, excellent machinability, and low thermal expansion coefficient. The recent development of High-Performance EDM Graphite Marble Mold has revolutionized the industry.High-Performance EDM Graphite Marble Mold is one of the most advanced forms of graphite molds available today. This type of mold is made using high-quality isostatic graphite, which is a versatile and durable material. It is ideally suited for producing intricate and complex metal castings. The use of isostatic graphite ensures that the molds are free from any internal defects or cracks, which can affect the quality of the final product.The High-Performance EDM Graphite Marble Mold also employs the technique of Electrical Discharge Machining (EDM) to produce a precise and accurate mold. EDM is an advanced machining process in which electrical discharges are used to shape the material. It is an effective process for producing complex shapes with very high accuracy. The use of EDM in graphite mold production ensures that the molds are of the highest quality and precision.One of the key advantages of using High-Performance EDM Graphite Marble Mold is its exceptional thermal conductivity. Graphite has one of the highest thermal conductivity rates of any material. This allows the mold to quickly heat up and cool down, which is essential for producing metal castings with a high degree of accuracy. Moreover, the low thermal expansion coefficient of graphite enables the mold to maintain its shape and dimensions even at high temperatures.Isostatically Bearing Metal Casting Molds are particularly challenging to produce due to their complex geometry and tight tolerances. However, the use of High-Performance EDM Graphite Marble Mold has made this process much more manageable. The exceptional precision and accuracy of these molds make them ideal for producing isostatically bearing metal castings with a high degree of quality and consistency.The production of High-Performance EDM Graphite Marble Mold is a highly specialized process that requires expertise and experience. It involves the use of advanced equipment and techniques such as CAD modeling, CNC machining, and EDM. Therefore, it is essential to work with a reputable and experienced custom graphite molds manufacturer who can deliver high-quality molds tailored to your specific requirements.In conclusion, the development of High-Performance EDM Graphite Marble Mold has improved the quality and consistency of isostatically bearing metal casting molds. These molds offer exceptional precision, accuracy, and thermal conductivity, which are essential for producing high-quality metal castings. The use of isostatic graphite and EDM technology ensures that these molds are of the highest quality and can meet even the most demanding requirements of the industry. Therefore, the widespread adoption of High-Performance EDM Graphite Marble Mold is expected to significantly improve the efficiency and productivity of the metal casting industry.

Top Graphite Rod Manufacturers and Suppliers in China - Mutual Benefits Await Overseas Customers

Graphite is one of the most commonly used materials in industries such as aerospace, automotive, and manufacturing. One of its unique properties is that it is a good conductor of electricity, making it ideal for use in products that require the transfer of electrical current. Graphite rods are a type of graphite product that is used in various applications.A graphite rod is a cylindrical bar made from a specific grade of graphite that is processed and machined to meet specific requirements. The rods are available in different diameters, lengths, and shapes. They are usually manufactured using high-purity graphite, which helps to improve their mechanical properties. Graphite rods are suitable for use in high-temperature, high-pressure, and corrosive environments.Teflon graphite rods are a type of graphite rod that is coated with Teflon, a fluoropolymer that is widely used in industries such as cooking, textiles, and aerospace. The Teflon coating helps to improve the overall characteristics of the graphite rod. Teflon graphite rods can withstand high temperatures and pressures, making them ideal for use in applications such as sealing systems, bearings, and gaskets.The use of Teflon graphite rods can help to reduce friction in machines and equipment, thereby improving their efficiency and performance. The Teflon coating can also help to protect the graphite rod from corrosion and chemical attack, thereby increasing its lifespan.Graphite rods are essential components in many industries, and their importance cannot be overstated. They are used in various applications such as nuclear reactors, aerospace, and automotive industries. Graphite rods have excellent thermal and electrical conductivity, which makes them ideal for use in products that require the transfer of electrical or thermal energy.In conclusion, Teflon graphite rods are a type of graphite rod that has been coated with Teflon. They are widely used in industrial applications where high temperatures and pressures are involved. The Teflon coating helps to improve the overall performance and lifespan of the graphite rod. Graphite rods, in general, are essential components in many industries, and their applications are limitless. They are an excellent choice for industry professionals who seek products with high thermal and electrical conductivity.

Advanced Sintering Box for High-Quality Hard Alloys

Sintering Box for Hard Alloy Enhances Manufacturing Efficiency and QualityThe advancements in technology have revolutionized various industries, and the manufacturing sector is no exception. One such innovation that has greatly impacted the manufacturing of hard alloys is the Sintering Box. This state-of-the-art equipment, which we cannot mention the brand name as per the request but will refer to as "the Sintering Box", offers numerous advantages to manufacturers, ultimately boosting efficiency and enhancing the quality of the final products.Hard alloys, commonly known as cemented carbides, are widely used in various industries due to their exceptional hardness, heat resistance, and wear resistance. These materials are primarily produced through the process of sintering, which involves compacting fine particles of metal powders and heating them to high temperatures. The Sintering Box stands as a vital component in this process, ensuring precise control over various parameters to achieve the desired properties in the final product.One of the most significant advantages of the Sintering Box is its ability to provide uniform and controlled heating. The equipment is equipped with advanced heating elements and temperature sensors, allowing manufacturers to achieve precise control over the sintering process. This uniform heating eliminates temperature inconsistencies within the sintering chamber, ensuring consistent material properties throughout the final product. As a result, manufacturers can produce hard alloys with enhanced mechanical strength and improved dimensional accuracy.Moreover, the Sintering Box also offers a safe and clean working environment. The equipment is equipped with advanced safety features, such as thermal insulation and automatic shut-off systems, ensuring the protection of operators and preventing any potential accidents. Additionally, the Sintering Box incorporates efficient gas circulation systems that help maintain a clean working atmosphere by removing harmful gases and smoke generated during the sintering process. This not only creates a healthier environment for the workers but also reduces the environmental impact of the manufacturing process.Furthermore, the Sintering Box significantly reduces production time and costs. Its advanced design optimizes the sintering cycle by minimizing heating and cooling durations without compromising the quality of the final product. This results in shorter production cycles and increased productivity, allowing manufacturers to meet growing market demands effectively. The equipment's efficiency also ensures energy savings, reducing manufacturing costs and making hard alloy production more economically viable for manufacturers in the long run.Incorporating the Sintering Box into hard alloy manufacturing processes offers manufacturers a competitive edge in terms of product quality and marketability. The precise control and uniform heating provided by this advanced equipment enable manufacturers to produce hard alloys with superior properties and consistent quality, meeting the rigorous requirements of various industries such as automotive, aerospace, and machining.It is worth mentioning that numerous manufacturing companies across the globe have already embraced the benefits of the Sintering Box and are reaping the rewards. One such company is {}, a leading manufacturer in the hard alloy industry. With over 20 years of experience, the company has established itself as a pioneer in implementing innovative technologies to improve the production of hard alloys. By leveraging the capabilities of the Sintering Box, they have witnessed substantial improvements in their manufacturing processes, achieving higher customer satisfaction and gaining a competitive advantage in the market.In conclusion, the Sintering Box has revolutionized hard alloy manufacturing by offering precise control, a safe working environment, reduced production time, and improved product quality. Its integration into the manufacturing process ensures manufacturers can meet the increasing market demands while maintaining high standards of excellence. As more companies embrace this cutting-edge technology, the future of hard alloy production looks promising, ultimately driving industrial growth and technological advancements.

Versatile Graphite Crucibles for Efficient Metal Melting

Gold And Silver Graphite Crucibles: Superior Quality and Performance for Your Melting NeedsChoosing the right crucible is important if you want to achieve accurate, reliable, and consistent results in your melting process. Whether you are a jeweler, a metalworker, or a manufacturer, you need a crucible that can withstand high temperatures, resist corrosive materials, and conduct heat effectively. Gold and silver graphite crucibles are ideal for melting precious metals because they offer superior quality and performance compared to other types of crucibles.One of the main advantages of graphite crucibles is their ability to withstand extreme temperatures without cracking or deforming. They can handle temperatures up to 3000°C, which makes them suitable for melting gold, silver, and other high-melting-point metals. Graphite crucibles also have excellent thermal conductivity, which means they transfer heat quickly and evenly throughout the material. This ensures that the metal melts evenly, reducing the risk of hotspots and uneven melting.Another advantage of graphite crucibles is their resistance to chemical corrosion. Graphite is inert and does not react with most acids, bases, or molten metals. This means that your crucible will not contaminate your metal with impurities or alter its properties. Plus, graphite crucibles are easy to clean and maintain, ensuring longevity and durability.When it comes to melting gold and silver, precision and accuracy are crucial. Graphite crucibles offer both. They are designed to provide consistent performance and precise temperature control, ensuring that your metal melts at the right temperature and time. This results in high-quality castings that meet your exact specifications.At (brand name removed), we offer a wide range of gold and silver graphite crucibles to meet your melting needs. Our crucibles are made from high-purity graphite and are designed for optimal performance. We also offer custom-made crucibles to fit your specific requirements. Our graphite crucibles come in various sizes and shapes, such as tapers, cylinders, and cones, and we can also provide crucibles with lids or without, depending on your preferences.Our graphite crucibles are carefully crafted to ensure quality and durability. We use advanced manufacturing techniques and quality control procedures to ensure that each crucible meets our rigorous standards. Our crucibles are lightweight and easy to handle, making them ideal for industrial and laboratory applications.In conclusion, gold and silver graphite crucibles offer a range of advantages over other types of crucibles. They are durable, heat-resistant, corrosion-resistant, and offer precise temperature control. They are ideal for melting high-melting-point metals such as gold and silver and produce high-quality castings. At (brand name removed), we provide superior-quality graphite crucibles that will meet your melting needs. Contact us today to learn more about our products and how they can improve your melting performance.

Latest data on the cost of graphite - find out more here

Graphite Cost, a leading provider of high-quality graphite products, continues to set the bar high in the industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner for businesses seeking reliable graphite solutions. Graphite Cost's commitment to excellence is evident in the superior quality of its products, as well as its unwavering dedication to meeting the diverse needs of its clients.Graphite Cost offers a wide range of graphite products, including graphite electrodes, graphite blocks, and graphite powder. These products are used in various industries such as steel production, metallurgy, and foundry operations. The company prides itself on delivering top-notch graphite solutions that are not only cost-effective but also environmentally friendly. With a team of experienced professionals, Graphite Cost has the capability to provide tailored graphite products to meet the specific requirements of its customers.In recent years, Graphite Cost has made significant investments in research and development to enhance its product offerings. By leveraging the latest technological advancements, the company has been able to develop new and improved graphite products that deliver exceptional performance and durability. This commitment to innovation has set Graphite Cost apart from its competitors and has helped solidify its position as a market leader in the graphite industry.One of the key factors that has contributed to Graphite Cost's success is its unwavering commitment to quality. The company adheres to stringent quality control measures at every stage of the production process to ensure that its products meet the highest standards. By maintaining strict quality standards, Graphite Cost has earned the trust and loyalty of its customers, who rely on the company's products to power their operations.Furthermore, Graphite Cost places a strong emphasis on customer satisfaction. The company takes a customer-centric approach, working closely with clients to understand their unique needs and provide them with the best possible graphite solutions. Whether it's providing technical support, product customization, or timely delivery, Graphite Cost goes above and beyond to ensure that its customers have a positive experience.In addition to its superior products and customer-centric approach, Graphite Cost is also committed to sustainability. The company recognizes the importance of environmental responsibility and strives to minimize its carbon footprint throughout its operations. By employing sustainable production practices and investing in eco-friendly technologies, Graphite Cost is doing its part to protect the planet while serving the needs of its customers.Looking to the future, Graphite Cost remains dedicated to pushing the boundaries of graphite innovation. The company continues to explore new avenues for product development and expand its market reach. With a strong track record of success and a clear vision for the future, Graphite Cost is poised to remain a top player in the graphite industry for years to come. As the demand for high-quality graphite products continues to rise, Graphite Cost is well-positioned to meet the needs of its customers and drive continued growth and success.In conclusion, Graphite Cost has established itself as a leading provider of top-quality graphite products, known for its commitment to innovation, quality, customer satisfaction, and sustainability. The company's dedication to excellence has earned it a strong reputation in the industry and positioned it for continued success in the years ahead. With a focus on continuous improvement and a customer-centric approach, Graphite Cost is set to remain a key player in the global graphite market.

8mm Graphite Rod Used in Various Industries for Its Exceptional Strength

Title: Advancements in Graphite Rod Technology Set to Revolutionize Various IndustriesIntroduction:Graphite rods have long been recognized as vital components in numerous industrial applications, offering enhanced strength, electrical conductivity, and resistance to high temperatures. XYZ Corporation, renowned for its cutting-edge research and development, has unveiled its groundbreaking 8mm Graphite Rod. This revolutionary product promises to transform industries, such as aerospace, automotive, electronics, and renewable energy, with its exceptional quality, performance, and durability.Paragraph 1:The aerospace industry, well-known for its stringent demands on materials, is set to benefit greatly from XYZ Corporation's innovative 8mm Graphite Rod. The strength-to-weight ratio of this advanced material is unparalleled, making it ideal for constructing lightweight yet robust aircraft components. The aerospace sector can anticipate increased fuel efficiency and reduced carbon emissions, as the incorporation of these graphite rods into aircraft structures will enable manufacturers to design more aerodynamic and fuel-efficient planes.Paragraph 2:In the automotive industry, where energy efficiency and sustainability are paramount, the XYZ Corporation's 8mm Graphite Rod will play a crucial role in the development of electric vehicles (EVs). By utilizing these rods in battery packs and cooling systems, automakers can enhance the overall performance and range of EVs. Furthermore, the exceptional heat resistance of graphite rods eliminates the need for additional cooling mechanisms, reducing the weight and complexity of EV components.Paragraph 3:Electronics manufacturing is an industry that requires materials with excellent electrical conductivity, thermal stability, and anti-corrosive properties. XYZ Corporation's 8mm Graphite Rod meets all these requirements and more, making it an ideal choice for the production of semiconductors, circuit boards, and various other electronic components. The introduction of this innovative product is poised to revolutionize electronics manufacturing, leading to more efficient and reliable devices.Paragraph 4:Furthermore, this remarkable graphite rod holds immense potential in the renewable energy sector, specifically in wind turbines and solar panels. The superior mechanical strength and durability of the XYZ Corporation's 8mm Graphite Rod ensure optimal performance and longevity in challenging environmental conditions. As the focus on renewable energy intensifies globally, this graphite rod will prove instrumental in enhancing the efficiency, enhancing productivity, and extending the lifespan of green energy infrastructure.Paragraph 5:XYZ Corporation has not only developed an exceptional product but also adopted eco-friendly manufacturing processes to support sustainability initiatives. The company's commitment to reducing carbon emissions and environmental impact sets a positive example for others in the industry. Additionally, its rigorous quality control measures, including thorough testing and compliance with international standards, affirm the reliability, consistency, and safety of the 8mm Graphite Rod.Conclusion:The introduction of XYZ Corporation's 8mm Graphite Rod marks a significant milestone in the industrial sector. With its exceptional strength, electrical conductivity, heat resistance and numerous other benefits, this innovative product is set to revolutionize industries such as aerospace, automotive, electronics, and renewable energy. As XYZ Corporation continues to push the boundaries of technological advancements, it reinforces its position as a global leader in graphite rod manufacturing, and industry stakeholders eagerly await the positive impact this new product will have on their respective fields.