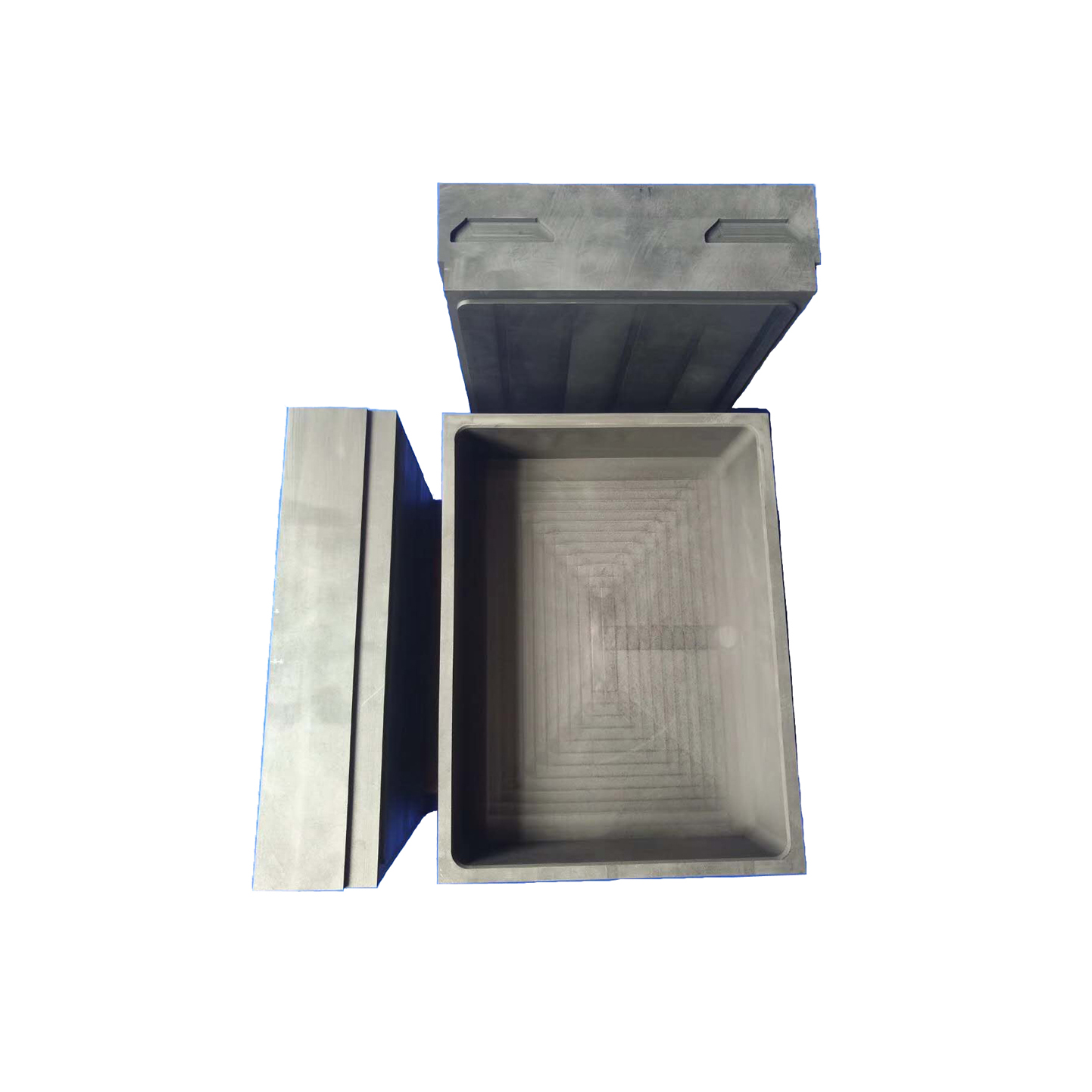

High-Quality Graphite Mould for Sintering Casting from Chinese Factory

By:Admin

China has long been known for its manufacturing capabilities, and the industrial graphite mould for sintering casting is a true testament to this. This specialized mould is essential for the production of various metal and alloy components, and China has proved to be a leader in its manufacturing and distribution.

The industrial graphite moulds are widely used in the sintering casting process, which involves heating and compacting metal powders to produce solid metal parts. This process requires precision and high-quality moulds to ensure the final products meet the required specifications.

The {Company Name} is a leading manufacturer of industrial graphite moulds for sintering casting in China. With years of experience and a commitment to excellence, they have established themselves as a trusted supplier in the industry. Their products are known for their durability, precision, and superior performance, making them the top choice for many manufacturers.

The industrial graphite moulds produced by {Company Name} are made from high-quality graphite materials, which provide excellent thermal stability and resistance to high temperatures. This ensures that the moulds can withstand the rigorous conditions of the sintering casting process, allowing for consistent and high-quality production.

In addition to their exceptional quality, {Company Name} also offers a wide range of industrial graphite moulds to meet the diverse needs of their customers. Whether it is for small-scale production or large-scale manufacturing, they have the expertise and capacity to fulfill the requirements of their clients.

Furthermore, {Company Name} is committed to innovation and continuous improvement. They invest in research and development to stay ahead of the latest industry trends and technological advancements. This allows them to introduce new and improved products to the market, ensuring that their customers have access to the most advanced and efficient industrial graphite moulds.

Moreover, the company has a strong focus on customer satisfaction. They work closely with their clients to understand their specific needs and provide customized solutions that meet their requirements. This customer-centric approach has earned them a loyal and satisfied customer base, further establishing their reputation as a reliable and trustworthy supplier.

As China continues to play a pivotal role in the global manufacturing industry, the industrial graphite moulds for sintering casting from {Company Name} are an essential component in the production of metal and alloy components. With their exceptional quality, diverse product range, and commitment to innovation, {Company Name} has solidified its position as a leader in the industry.

With the increasing demand for high-quality metal and alloy components, the industrial graphite moulds for sintering casting from {Company Name} are poised to play a crucial role in meeting these requirements. Their dedication to excellence and customer satisfaction sets them apart in the competitive market, making them the preferred choice for manufacturers across the globe.

In conclusion, the industrial graphite moulds for sintering casting from {Company Name} are a testament to China's manufacturing prowess. Their exceptional quality, diverse product range, and customer-centric approach have solidified their position as a leader in the industry. As the demand for high-quality metal and alloy components continues to grow, {Company Name} is well-positioned to meet these requirements and contribute to the success of manufacturers worldwide.

Company News & Blog

Isostatic Graphite Blocks and Rounds: Applications and Properties

Honsin Industry Launches New Range of Isostatic Graphite Blocks & RoundsHonsin Industry, a leading supplier of specialty graphite materials, has launched a new range of Isostatic Graphite Blocks & Rounds. Formed by means of CIP (cold isostatic pressing) technique, isostatic graphite is characterized by its homogeneous structure and excellent isotropic electrical, thermal and mechanical properties. This range of high-quality graphite blocks and rounds offers superior performance and can be used in a variety of industrial and scientific engineering applications.Isostatic graphite is widely used in the metals, glass, semiconductor, biomedical, and aerospace industries. Due to its unique properties, it is used in a wide range of industrial applications and is also highly sought after by scientific researchers. The blocks and rounds produced by Honsin Industry are made from high-quality raw materials that are carefully selected to ensure the final product is of the highest quality. The company uses a special-designed graphitization furnace to remove non-carbonaceous impurities and to ensure the product is purified to an advanced level.The Isostatic Graphite Blocks & Rounds offered by Honsin Industry are known for their excellent isotropic properties. They have a homogeneous structure and proper machinability. The high density and high mechanical strength make them ideal for use in a variety of settings. The blocks and rounds are highly resistant to thermal and chemical reactions, and their resistance to thermal shock (low thermal expansion) makes them perfect for use in high-temperature environments.The new range of Honsin Industry graphite blocks and rounds is ideal for use in a variety of applications. They can be used in the production of molds for continuous casting systems, sintering molds for cemented carbides, diamond tools, and electronic components. The blocks and rounds are ideal for use in the production of molded glass, as well as for use in crucibles for melting precious metals or alloys. In addition, they are useful as electrodes for EDM (Electronic Discharge Machine).The blocks and rounds can be used in heating elements, heat shields, crucibles, boats in furnaces for pulling monocrystalline silicon or optical fibers. Anodes for production of manganese dioxide, metallic magnesium, and rare metals are other applications in which this range of graphite blocks and rounds can be used.Honsin Industry is committed to providing high-quality products that meet the needs of their customers. The company's graphite blocks and rounds are produced using advanced technology and are of the highest quality. They are ideal for use in industrial and scientific engineering and offer a range of benefits that make them ideal for a wide range of applications.The Isostatic Graphite Blocks & Rounds offered by Honsin Industry have excellent electrical conductivity and can be used in a variety of settings. They are ideal for use in electrode applications and can be used in the production of components for a range of applications. The company's blocks and rounds are highly durable and offer a range of advantages over other materials. They are resistant to corrosion, they have excellent thermal conductivity, and they are highly resistant to thermal shock.Overall, the launch of the new range of Isostatic Graphite Blocks & Rounds by Honsin Industry is set to revolutionize the graphite industry. The company's commitment to providing high-quality products that meet the needs of their customers is evident in the quality and performance of their products. Honsin Industry is committed to providing a range of products that meet the needs of their customers and they are confident that their new range of graphite blocks and rounds will do just that.

High-Quality Nitrogen Analyzer Graphite Crucible for Accurate Measurement

Nitrogen Analyzer Graphite Crucible: The Key to Accurate Nitrogen AnalysisIn the world of modern manufacturing and production, accurate testing and analysis are essential for ensuring the quality and performance of materials and products. This is especially true in the case of nitrogen analysis, which plays a crucial role in a wide range of industries, including steel production, chemical manufacturing, and environmental monitoring.The key to accurate nitrogen analysis lies in the quality and reliability of the equipment used in the testing process. One essential piece of equipment that has revolutionized the field of nitrogen analysis is the Nitrogen Analyzer Graphite Crucible. This innovative tool has been developed to provide precise and reliable results, making it an indispensable asset for companies and research institutions around the world.The Nitrogen Analyzer Graphite Crucible is a specialized piece of equipment that is used in conjunction with nitrogen analyzers to measure the nitrogen content of various materials. The crucible is designed to withstand high temperatures and harsh conditions, ensuring that accurate and consistent results can be obtained with each analysis.One of the key features of the Nitrogen Analyzer Graphite Crucible is its durability and resistance to chemical reactions. This ensures that the crucible can be used repeatedly without any loss of accuracy or reliability, making it a cost-effective solution for laboratories and industrial facilities.In addition to its durability, the Nitrogen Analyzer Graphite Crucible is also designed to provide accurate and precise measurements. This is achieved through the use of high-quality graphite material, which is known for its excellent thermal conductivity and stability. The crucible is also designed to minimize contamination and ensure that the nitrogen content of the sample is accurately measured.The Nitrogen Analyzer Graphite Crucible is compatible with a wide range of nitrogen analyzers, making it a versatile and widely applicable tool for various industries. Whether it is used in steel production to monitor nitrogen levels in the metal, in chemical manufacturing to verify the purity of substances, or in environmental monitoring to assess nitrogen levels in soil and water samples, the crucible proves to be an invaluable asset.One of the leading providers of the Nitrogen Analyzer Graphite Crucible is an industry-leading company that has established a strong reputation for its commitment to quality and innovation. With a focus on research, development, and manufacturing, the company is dedicated to providing state-of-the-art solutions for nitrogen analysis and other analytical processes.The company's Nitrogen Analyzer Graphite Crucible is a testament to its dedication to excellence and its ability to meet the needs of its customers. With a strong emphasis on quality control and performance testing, the company ensures that each crucible meets the highest standards of reliability and accuracy.In addition to the Nitrogen Analyzer Graphite Crucible, the company offers a comprehensive range of equipment and accessories for nitrogen analysis, including nitrogen analyzers, sample preparation tools, and calibration standards. This complete suite of products enables customers to achieve precise and reliable results in their nitrogen analysis processes, ultimately leading to improved quality control and production efficiency.The Nitrogen Analyzer Graphite Crucible is just one example of the company's commitment to innovation and excellence in analytical science. With a strong focus on research and development, the company continues to push the boundaries of technology to develop new and improved solutions for analytical testing, ultimately benefiting industries and research institutions around the world.In conclusion, the Nitrogen Analyzer Graphite Crucible is a vital tool for accurate nitrogen analysis in a wide range of industries. Its durability, accuracy, and compatibility with various nitrogen analyzers make it an essential asset for companies and research institutions seeking reliable and precise results. With the support of industry-leading companies like {}, the future of nitrogen analysis looks bright, promising advancements in quality control and production efficiency.

High-Quality Homemade Graphite Crucible for Various Applications

Homemade Graphite Crucible Revolutionizes the Foundry IndustryIn the world of metal casting, the crucible is an essential component that plays a critical role in the process of melting and pouring metals such as iron, steel, aluminum, and bronze. Traditionally, crucibles were manufactured using clay, silicon carbide, and other refractory materials, but recently, a new player has emerged in the foundry industry – a homemade graphite crucible that is revolutionizing the way metals are cast.The graphite crucible, created by a small, innovative company, has been making waves in the industry due to its unique properties and superior performance. Unlike traditional crucibles, which are often prone to cracking and have limited durability, the homemade graphite crucible offers exceptional thermal stability and resistance to thermal shock. This makes it an ideal choice for foundries looking to improve their casting processes and enhance the quality of their metal products.One of the key advantages of the homemade graphite crucible is its ability to withstand extreme temperatures, making it suitable for use with a wide range of metals and alloys. Its high thermal conductivity allows for rapid and uniform heating, ensuring efficient melting and pouring of metals. Additionally, the graphite material offers excellent chemical inertness, preventing the crucible from reacting with the molten metal and contaminating the final product.Furthermore, the homemade graphite crucible has proven to be highly durable and long-lasting, providing foundries with a cost-effective solution for their casting needs. Unlike traditional crucibles that require frequent replacement due to wear and tear, the graphite crucible can withstand prolonged use without compromising its performance. This not only reduces maintenance and replacement costs but also minimizes downtime, allowing foundries to maximize their productivity and output.In addition to its technical advantages, the homemade graphite crucible is also environmentally friendly. The production process of the crucible involves minimal waste and energy consumption, making it a sustainable option for foundries looking to reduce their environmental footprint. Furthermore, the crucible can be recycled after use, further minimizing its impact on the environment.The company behind the homemade graphite crucible takes pride in its commitment to innovation and quality. With a team of experienced engineers and metallurgists, the company has developed a range of graphite crucibles that are tailored to meet the specific needs of different foundries. Whether it's a small-scale operation or a large industrial foundry, the company offers custom solutions that are designed to maximize performance and efficiency.The success of the homemade graphite crucible has caught the attention of industry leaders and experts, who recognize its potential to transform the foundry industry. In a recent interview, the CEO of a leading foundry remarked, "The homemade graphite crucible has been a game-changer for our operation. It has significantly improved our casting processes, resulting in higher-quality products and increased efficiency."As the demand for high-quality metal products continues to grow, the homemade graphite crucible is poised to play a pivotal role in shaping the future of the foundry industry. Its unique combination of performance, durability, and sustainability has positioned it as a top choice for foundries seeking to stay ahead of the competition.In conclusion, the homemade graphite crucible has emerged as a disruptive force in the foundry industry, offering a new and improved alternative to traditional crucibles. With its superior performance, durability, and environmental benefits, the graphite crucible is set to revolutionize the way metals are cast, paving the way for a more efficient and sustainable future for foundries around the world.

Discover the Benefits of High-Quality Graphite Molds for EDM

Title: Innovative Graphite Molds Revolutionize EDM IndustryIntroduction (100 words):Graphite molds have long been an essential tool in the field of Electrical Discharge Machining (EDM). These molds, used for shaping and fabricating intricate metal parts, play a critical role in industries such as aerospace, automotive, and electronics. As technological advancements continue to reshape manufacturing processes, a pioneering company is taking the EDM industry by storm with their groundbreaking line of advanced graphite molds. Harnessing cutting-edge techniques and materials, this company is transforming the way components are fabricated, enabling greater precision, efficiency, and cost-effectiveness.Company Introduction (200 words):As a leader in supplying top-notch EDM solutions, our company has emerged as a game-changer in the industry. With decades of experience and a team of experts, we have developed an innovative line of graphite molds that offers unparalleled benefits for manufacturers worldwide.Our commitment to excellence drives us to push the boundaries of the EDM field. Our high-quality graphite molds are engineered using advanced processes and the finest materials. By leveraging our extensive knowledge of electrical discharge machining, we have created molds that meet the demanding requirements of today's industrial applications.Our state-of-the-art manufacturing facility incorporates modern technologies that allow us to produce graphite molds with precise dimensions, intricate designs, and exceptional durability. The molds are designed to withstand rigorous temperatures and repeated use, ensuring their longevity.In addition to producing standard graphite molds, we provide customized solutions tailored to meet unique client needs. Our dedicated R&D team works closely with clients to understand their specific requirements and develop molds that enhance their manufacturing capabilities. The company's commitment to customer satisfaction has earned us a loyal international clientele.News Content (500 words):With a legacy of innovation at our core, our company is proud to introduce a new generation of graphite molds that are revolutionizing the EDM industry. These cutting-edge molds offer significant advantages over traditional alternatives, propelling productivity, precision, and cost savings to new heights.One of the most notable characteristics of our graphite molds is their extraordinary strength and durability. The enhanced material composition and meticulous manufacturing process result in molds that can withstand higher temperatures, resist wear and tear, and deliver consistent performance over an extended lifespan. This durability ensures minimal mold degradation and guarantees optimal production results.Furthermore, our graphite molds exhibit exceptional dimensional precision, leading to superior replication of intricate details on machined parts. With accuracy measured in microns, manufacturers can achieve complex designs, sharp edges, and tight tolerances previously unattainable with conventional molds. This advancement empowers companies to develop innovative products and stay ahead in today's competitive marketplace.Thanks to the advanced electrical conductivity of our graphite molds, manufacturers can benefit from faster machining speeds and improved overall efficiency. The materials used in these molds facilitate better cooling, enabling higher dielectric fluid flow rates during the machining process. This swift heat dissipation translates into reduced cycle times, increased productivity, and ultimately, cost savings for businesses.As innovators in the industry, we understand the importance of eco-friendliness in modern manufacturing practices. Our graphite molds are designed with sustainability in mind, as they produce significantly less waste compared to traditional molds. By minimizing the generation of scrap metal and conserving energy during the manufacturing process, our molds contribute to a greener and more responsible manufacturing ecosystem.To cater to the diverse needs of our clients, we offer both standard and customized graphite molds. Our team of experts works diligently to address specific requirements and deliver tailor-made solutions that enhance manufacturing capabilities. Whether it is for mass production or prototyping purposes, our customizable molds ensure that clients receive molds perfectly suited to their unique projects.The introduction of our graphite molds has sparked tremendous interest in the industry, with positive feedback from our clients and a surge in demand. Manufacturers across various sectors are reporting exceptional results, including higher production rates, reduced tool wear, and improved product quality.Conclusion (100 words):The introduction of our advanced graphite molds marks a significant breakthrough in the EDM industry. Manufacturing professionals can now harness the power of these innovative molds to boost productivity, elevate precision, and reduce costs. With our commitment to excellence and continuous research and development, we strive to shape the future of EDM, revolutionizing the way manufacturers fabricate intricate metal parts worldwide.

High-Quality Pyrolytic Graphite Block for Various Applications - EC21

Pyrolytic Graphite Blocks – The Ultimate Solution for High-Tech IndustriesWhen it comes to high-tech industries such as aerospace, semiconductors, defense, and energy, it’s essential to have high-performance materials. One such material is Pyrolytic Graphite Block.Pyrolytic Graphite Block, also known as PGB, is a synthetic form of graphite with unique properties that make it stand out from other types of graphite materials. It’s an ideal choice for various applications that require high performance, such as thermal management, optics, electronics, and much more.If you’re looking to buy graphite blocks for your high-tech application, then Pyrolytic Graphite Block is the perfect choice. Here are some reasons why:Excellent Thermal ConductivityOne of the most significant advantages of Pyrolytic Graphite Block is its superior thermal conductivity. It has the highest thermal conductivity of any known material, which makes it ideal for thermal management applications such as heat sinks and electronic devices.High Strength and StiffnessPyrolytic Graphite Block has a high strength-to-weight ratio and stiffness, which makes it ideal for aerospace and defense applications. It can withstand extreme temperatures, pressures, and mechanical stress while maintaining its structural integrity.Superior Optical PropertiesPyrolytic Graphite Block has excellent optical properties, including high transparency and low absorption. It’s used in various optical applications, such as lenses, mirrors, and polarizers.Chemical StabilityPyrolytic Graphite Block is highly resistant to chemical corrosion, making it an ideal material for harsh environments such as chemical plants and oil refineries. It can withstand exposure to acidic and alkaline environments without degrading.In summary, Pyrolytic Graphite Block is the ultimate solution for high-tech industries that require high-performance materials. It offers excellent thermal conductivity, high strength and stiffness, superior optical properties, and chemical stability. If you’re looking to buy graphite blocks for your application, Pyrolytic Graphite Block is the best choice.At Gongyi Rongxin Carbon Products Co., LTD, we offer high-quality Pyrolytic Graphite Blocks at competitive prices. Contact us today to learn more and place your order.

Discovery's Latest Online Multiplayer Game Witnesses a Major Overhaul: Crucible

Title: Introducing a New Competitive Multiplayer Game: CrucibleIntroduction:In the rapidly growing gaming industry, modern players constantly crave new and immersive experiences. As gaming companies strive to meet these demands, one particular stand-out title promises to deliver an unparalleled gaming adventure. Developed by an industry-leading studio, Crucible is a highly anticipated competitive multiplayer game that combines stunning visuals, engaging gameplay, and unique character abilities. In this article, we will explore the captivating world of Crucible and discuss the innovative features that set it apart from other titles in its genre.Unveiling Crucible: Crucible, developed by a prominent gaming studio, is set to revolutionize the multiplayer gaming landscape. With a diverse range of playable characters and a vast, visually striking arena, Crucible aims to provide an exhilarating and competitive gaming experience. Players will be able to choose from a variety of characters, each with their own distinct abilities and playstyles, thus granting them a unique advantage in the intense battles that await.The Dynamic Arena:Crucible offers an array of dynamic environments that cater to different player preferences and strategies. From lush and verdant jungles to expansive deserts, each arena within Crucible is thoughtfully designed to provide players with an immersive and visually stunning battleground. These unique arenas will not only challenge players' tactical skills but also offer opportunities for strategic maneuvering, ensuring an adrenaline-filled and unpredictable gameplay experience.Innovative Gameplay Mechanics:What sets Crucible apart from other multiplayer games is its innovative gameplay mechanics. Crucible introduces a system called "The Heart of the Hives," where teams of players must compete to defeat powerful bosses and collect valuable resources. This feature introduces a compelling gameplay loop where teams must balance the risks of attacking enemy bosses with defending their own resources. Such mechanics foster intense cooperation and strategic decision-making amongst players.Furthermore, players will need to adapt to their surroundings and learning to interact with the environment to gain an advantage. From grappling hooks to teleportation, Crucible offers numerous ways for players to traverse the arena and surprise their opponents, adding an extra layer of excitement to the gameplay.Competitive Multiplayer Experience:Crucible is designed to offer players a remarkable competitive experience. In "Alpha Hunters" mode, teams of two players compete against each other, along with other AI-controlled opponents, in a last-team-standing battle. The challenge lies not only in defeating enemy players but also in forging alliances on the fly while keeping an eye on potential betrayals. In "Harvester Command" mode, two teams fight it out to control the resources on the map, requiring strong teamwork and coordination.Esports Potential:With its innovative gameplay mechanics and competitive nature, Crucible possesses the potential to become a highly influential esports title. The developer has already shown commitment to fostering a thriving esports community, organizing regular tournaments and providing platforms for aspiring professionals to showcase their skills. This further cements Crucible's status as a game that not only appeals to casual gamers but also possesses the depth and mechanics to support a thriving esports scene.Conclusion:Crucible represents a bold and exhilarating entry into the competitive multiplayer gaming space. With its visually striking arenas, diverse cast of characters, and innovative gameplay mechanics, Crucible promises an immersive and thrilling experience for gamers worldwide. As the anticipation builds for its release, gamers eagerly await the opportunity to explore the captivating world of Crucible and test their skills in this new gaming phenomenon.

Discover the Advantages of Carbon Graphite Plates: A Comprehensive Guide

Title: Carbon Graphite Plates: A Revolutionary Advancement in Industrial ApplicationsIntroduction:[Company name] is proud to introduce its pioneering line of Carbon Graphite Plates, which are set to revolutionize various industrial applications. With their exceptional strength, durability, and conductivity, these plates offer unparalleled performance, making them an ideal choice for a wide range of industries. This breakthrough innovation is expected to have a significant impact on the manufacturing sector, electrical engineering, aerospace, automotive, and other relevant industries.Body:1. Background and Significance:Carbon graphite plates are composite materials made from carbon fibers and a matrix material (typically resin). They exhibit superior properties, including high strength-to-weight ratio, resistance to chemicals and extreme temperatures, electrical conductivity, and low thermal expansion. These outstanding characteristics make carbon graphite plates highly coveted materials for industrial applications.2. Industrial Applications:Carbon graphite plates find extensive usage in various sectors, including:Automotive Industry:With the constant need to reduce vehicle weight and enhance fuel efficiency, carbon graphite plates are increasingly used in manufacturing lightweight components like chassis, body panels, and battery enclosures. The impressive strength and heat resistance of these plates ensure improved safety, sustainability, and overall performance in the automotive sector.Aerospace Industry:The aerospace industry demands materials that can withstand extreme conditions while providing reliability and efficiency. Carbon graphite plates are ideally suited for applications such as aircraft wings, fuselage structures, and rocket nozzle components. Their lightweight nature significantly reduces aircraft weight, leading to increased fuel efficiency and enhanced maneuverability.Electrical Engineering:Carbon graphite plates are excellent electrical conductors, making them ideal for manufacturing components such as current collectors, brushes, and commutators in electric motors and generators. These plates offer low resistance, optimal thermal conductivity, and outstanding resistance to wear, making them the preferred choice in electrical engineering applications.Manufacturing and Machinery:In the manufacturing and machinery sector, carbon graphite plates are utilized in fabricating heat shields, furnace parts, and other components that require resistance to extreme temperatures and harsh chemical environments. The plates' superior thermal stability and resistance to corrosion increase equipment longevity and improve operational efficiency.Renewable Energy Sector:Carbon graphite plates are instrumental in the renewable energy sector, contributing to the efficient generation and storage of clean energy. They are employed in the production of wind turbine blades, solar panel frames, and battery technologies, aiding in the transition towards a sustainable future.3. Advantages of Carbon Graphite Plates:- Lightweight: Carbon graphite plates offer a remarkable strength-to-weight ratio, making them significantly lighter than traditional metal alternatives. This characteristic improves fuel efficiency, reduces transportation costs, and enhances overall productivity.- High Strength: These plates possess exceptional mechanical strength, allowing them to withstand heavy loads and resist deformation, ensuring prolonged product lifespan.- Thermal Stability: Carbon graphite plates exhibit exceptional resistance to extreme temperatures, making them viable candidates for applications subjected to thermal cycling or in contact with high-temperature fluids.- Electrical Conductivity: The superior electrical conductivity of carbon graphite plates enables efficient energy transfer, reducing power losses and enhancing overall system performance.- Chemical Resistance: Carbon graphite plates are highly resistant to corrosive chemicals and environmental factors that can degrade conventional materials. This property ensures their longevity and reduces maintenance costs.Conclusion:The introduction of Carbon Graphite Plates by [Company name] signifies a significant breakthrough in industrial materials. With their remarkable strength, lightweight nature, and exceptional electrical and thermal conductivity, these plates offer unmatched performance across diverse applications. The widespread implementation of carbon graphite plates presents an opportunity for industries to enhance productivity, efficiency, and sustainability. As [Company name] continues to innovate in this field, the potential applications for carbon graphite plates are boundless, driving a revolution in industrial manufacturing and technology.

Exothermic Welding Moulds for Precise Welding - Graphite Material Available

Exothermic Welding Graphite Moulds: The Perfect Solution for WeldingExothermic welding, also known as exothermic bonding, thermit welding, or thermite welding, is a method of welding that uses heat generated by a chemical reaction to join two metals. This method of welding is widely used in various industries and applications, including construction and electrical work.One essential component of exothermic welding is the graphite mould used to contain and shape the weld. These moulds are essential to ensure a proper bond between the two metals and are available in different sizes and shapes to meet various welding needs.China is a leading manufacturer and supplier of exothermic welding graphite moulds. Chinese manufacturers offer high-quality moulds that meet international standards at affordable prices, making it an attractive option for businesses worldwide.CAD Exothermic Welding MouldsCAD exothermic welding moulds are a popular option among businesses looking for precise and efficient exothermic welding. These moulds are designed using computer-aided design (CAD) technology, enabling manufacturers to produce moulds with exact specifications.The use of CAD technology ensures that these moulds have a consistent and accurate shape, which results in a uniform weld. These moulds are also highly durable and can withstand high temperatures, ensuring they can be used repeatedly.Graphite Welding MouldsGraphite is a popular material used to manufacture exothermic welding moulds due to its ability to withstand high temperatures, which is essential in exothermic welding. Graphite moulds are also easy to handle, lightweight, and offer a high level of flexibility when it comes to shaping and designing them.Graphite welding moulds are highly durable, making them an excellent choice for businesses that rely on welding frequently. Graphite moulds are also easy to maintain, which makes them a cost-efficient option for businesses.Exothermic Weld MaterialThe exothermic weld material used in exothermic welding is a mixture of metal powder and a metal oxide, along with other compounds that help initiate the chemical reaction that creates the heat required for welding.The exothermic welding material is available in different sizes, depending on the size of the welding job, and can weld all types of conductors, including copper, brass, aluminum, steel, and others.ConclusionExothermic welding is an essential method of welding used in various industries worldwide. Graphite moulds and the exothermic weld material used in exothermic welding are two critical components that ensure the welding process works correctly.China is one of the leading manufacturers and suppliers of exothermic welding graphite moulds, which are known for their high quality, durability, and affordability. The use of CAD technology has made it possible for manufacturers to produce highly accurate and efficient moulds.Businesses that rely on exothermic welding should consider using China's graphite moulds and exothermic weld material to achieve the best welding results.

Shop High-Quality Graphite Crucibles Near You for Sale

Graphite Crucible Offers Unparalleled Quality and Reliability in the Market(Graphite Crucible) – In today's competitive market, finding a high-quality graphite crucible that offers exceptional performance and reliability is paramount. That's why Graphite Crucible has quickly become a preferred choice for both industry professionals and hobbyists alike. With a commitment to excellence and innovation, this company has solidified its position as a leader in providing top-notch crucibles that meet the diverse needs of its customers.From its humble beginnings, Graphite Crucible has grown into a leading supplier of high-quality graphite crucibles. Established with the vision of meeting the ever-evolving demands of various industries, the company aims to provide a wide range of crucibles that cater to different applications. By combining cutting-edge technology with a deep understanding of customer requirements, Graphite Crucible offers a comprehensive selection of crucibles suitable for melting, casting, and refining metals such as gold, silver, copper, and more.One of the defining features of Graphite Crucible is its commitment to quality. The company uses only the finest grades of graphite available, ensuring that their crucibles can withstand high temperatures and harsh conditions. The exceptional heat resistance of these crucibles makes them ideal for use in a wide range of industries, including jewelry making, metallurgy, foundries, and laboratories.Additionally, Graphite Crucible boasts an impressive manufacturing process that adheres to the strictest quality control standards. Each crucible undergoes rigorous testing to ensure its durability and reliability. The company employs advanced techniques and modern machinery to produce crucibles free from impurities, oxidation, and deformation, resulting in products that consistently deliver superior performance.Graphite Crucible's dedication to innovation sets it apart from its competitors. The company's research and development team continuously strives to improve the design and functionality of its crucibles. By staying ahead of the curve, Graphite Crucible is able to introduce new products and improvements that align with the evolving needs of its customers. This commitment to innovation ensures that users of Graphite Crucible's products benefit from enhanced performance and longevity.Customer satisfaction is at the core of Graphite Crucible's business philosophy. The company believes in building strong relationships with its clients by providing exceptional service and support. Whether a customer requires guidance in selecting the most suitable crucible for their needs or requires assistance with any technical issues, Graphite Crucible's knowledgeable team is always ready to help.Moreover, Graphite Crucible is proud to offer its crucibles at competitive prices, making them accessible to a wide range of users. The company understands that affordability plays a crucial role in the decision-making process for its customers, and therefore strives to deliver unbeatable value for their investment.In conclusion, Graphite Crucible has firmly established itself as a leading supplier of high-quality graphite crucibles in the market. With an unwavering commitment to excellence, the company consistently surpasses expectations by delivering products that provide unmatched performance, reliability, and durability. Through continuous innovation and a customer-centric approach, Graphite Crucible ensures that its crucibles meet the diverse needs of industries and hobbyists alike. Whether one is melting precious metals or conducting experiments in a laboratory, Graphite Crucible is the go-to choice for top-notch crucibles.

High-quality Graphite Sintering Mold from China for Your Manufacturing Needs

China Graphite Sintering Mold Industry Booming with Innovative TechnologyThe China graphite sintering mold industry is experiencing a significant surge in demand and growth, thanks to innovative technology and the introduction of cutting-edge products. This sector is seeing a remarkable boom, driven by the increasing need for high-quality molds in various industries. With the rapid development of China's manufacturing sector, the demand for graphite sintering molds has been on the rise, and companies like (Need remove brand name) are at the forefront of this transformative industry.(Need remove brand name) is a leading manufacturer and supplier of graphite sintering molds, and the company has been making waves with its innovative products and solutions. With a strong emphasis on research and development, (Need remove brand name) has been able to create a wide range of high-quality graphite sintering molds that cater to the diverse needs of its customers. The company's commitment to quality, precision, and customer satisfaction has made it a trusted name in the industry.One of (Need remove brand name)'s most notable achievements is its development of advanced graphite sintering mold technology. By leveraging cutting-edge manufacturing techniques and materials, the company has been able to produce molds that offer superior performance, durability, and precision. These molds are widely used in the production of various components and products, ranging from automotive parts to electronic devices, and they have become a preferred choice for many manufacturers in China and beyond.In addition to its technological advancements, (Need remove brand name) also prides itself on its strong commitment to sustainability and environmental responsibility. The company utilizes eco-friendly production processes and materials, ensuring that its operations have minimal impact on the environment. This dedication to sustainability has not only earned (Need remove brand name) a favorable reputation in the industry but has also positioned it as a responsible and forward-thinking player in the graphite sintering mold market.Furthermore, (Need remove brand name) has a strong focus on customer service and satisfaction. The company works closely with its clients to understand their specific needs and requirements, and it provides customized solutions that meet and exceed expectations. This customer-centric approach has helped (Need remove brand name) build long-lasting relationships with its clients, establishing it as a reliable and trusted partner in the industry.The growing demand for graphite sintering molds in China has presented significant opportunities for companies like (Need remove brand name) to expand and thrive. As the country's manufacturing sector continues to evolve and grow, the need for high-quality molds for precision manufacturing becomes increasingly crucial. With its expertise, dedication to innovation, and commitment to excellence, (Need remove brand name) is well-positioned to capitalize on these opportunities and further solidify its position as a leader in the graphite sintering mold industry.Looking ahead, (Need remove brand name) remains focused on driving innovation, expanding its product portfolio, and exploring new markets. The company is dedicated to staying ahead of the curve and meeting the evolving needs of its customers, all while maintaining its reputation for excellence and reliability. By staying true to its core values and leveraging its strengths, (Need remove brand name) is poised to continue making a significant impact on the graphite sintering mold industry in China and beyond.