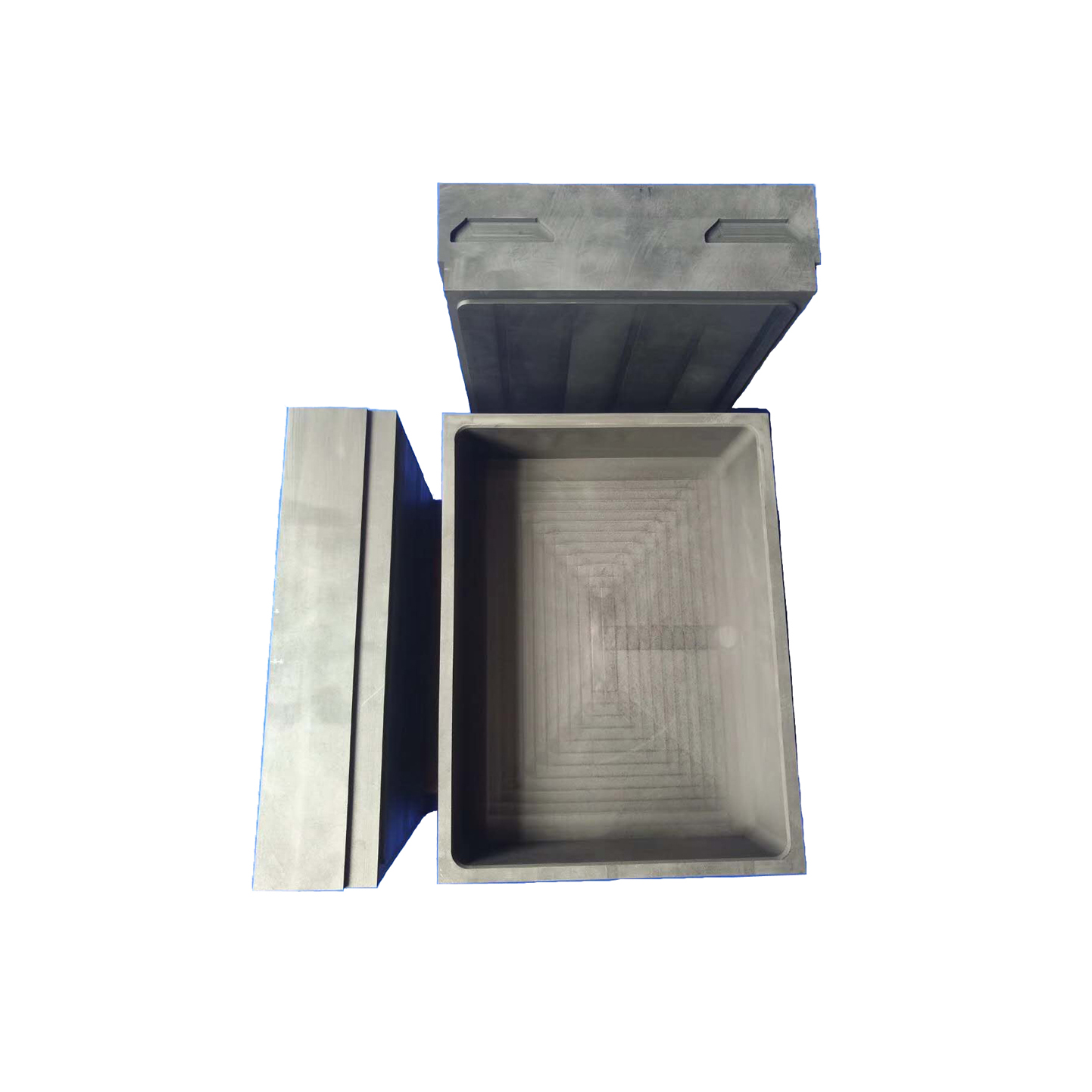

Newly Designed Graphite Box for Anode Powder Unveiled in the Market

By:Admin

{Company name} is a well-established and reputable company that specializes in the production and distribution of high-quality graphite products. With years of experience and expertise in the industry, the company has earned a strong reputation for delivering innovative and reliable solutions to its customers.

The introduction of Graphite Box For Anode Powder is a testament to the company's commitment to continuous innovation and improvement. The new product is designed to address the challenges associated with the storage and transportation of anode powder, providing a safer, more efficient, and cost-effective solution for customers.

The Graphite Box For Anode Powder features a durable and robust construction, ensuring the safe and secure storage of anode powder during transit and storage. The use of high-quality graphite materials provides excellent thermal and electrical conductivity, as well as superior resistance to corrosion and high temperatures, making it an ideal solution for the storage of anode powder.

Furthermore, the innovative design of the Graphite Box For Anode Powder includes features such as secure locking mechanisms, airtight seals, and ergonomic handles for easy handling and transportation. These features not only ensure the safety of the anode powder but also make the box easy to handle and transport, saving time and effort for customers.

In addition to its functional design, the Graphite Box For Anode Powder also boasts a sleek and modern aesthetic, reflecting the company's commitment to quality and innovation. The attention to detail and precision in manufacturing further reinforces the company's dedication to providing top-notch products to its customers.

The introduction of the Graphite Box For Anode Powder has already garnered significant interest from customers within the industry. The product has generated a great deal of excitement, with many customers expressing their enthusiasm for the improved safety and efficiency benefits it offers.

"We are thrilled to introduce the Graphite Box For Anode Powder to the market," said a spokesperson for {Company name}. "This innovative product is the result of our team's hard work and dedication to providing the best solutions to our customers. We believe that the Graphite Box For Anode Powder will set a new standard for the storage and transportation of anode powder, and we are confident that it will make a positive impact on our customers' operations."

The company has also emphasized its commitment to sustainability and environmental responsibility in the production of the Graphite Box For Anode Powder. The use of high-quality, eco-friendly materials and efficient manufacturing processes align with the company's values and goals, further demonstrating its dedication to responsible business practices.

As the demand for high-quality graphite products continues to grow, {Company name} remains at the forefront of the industry, leading the way with its innovative solutions and commitment to customer satisfaction. The introduction of the Graphite Box For Anode Powder is a clear example of the company's ability to anticipate and address the evolving needs of its customers, solidifying its position as a trusted and reliable partner in the graphite industry.

Company News & Blog

Discover the Benefits of Exothermic Welding Molds for Efficient Joining Processes

Exothermic Welding Mold Makes Strong Connections for Industrial ApplicationsExothermic welding, also known as cadwelding, is a popular method in the industrial sector for creating strong connections between two wires, cables or metal surfaces. This process involves a controlled explosion created by a chemical reaction that melts the wire ends and filler material, joining them into a homogeneous mass. The resulting connection is high conductivity, corrosion-resistant, and mechanically strong, which makes it ideal for applications in power and telecommunications industries.One of the critical components of exothermic welding is the mold, which holds the wires and filler material in place during the reaction. The mold must be precisely designed and manufactured to ensure a uniform reaction and consistent results. A leading player in this field is a company that produces exothermic welding molds of the highest quality, with superior materials, innovative design, and strict quality control.This company has been in the industry for many years, supplying a vast range of products to customers around the world. They have invested heavily in research and development, as well as manufacturing facilities, to ensure their molds meet the most stringent standards. They have also established a robust logistics network to deliver products in a timely and cost-effective manner.Their exothermic welding molds are designed for use in a wide range of applications, from low-voltage grounding and bonding to high-voltage transmission and distribution. They are suitable for joining copper, aluminum, brass, and steel wires, and can accommodate various sizes and shapes. Their molds come in different configurations, including vertical, horizontal, and angled, to meet specific customer requirements.The company's exothermic welding molds are made from high-quality materials, such as graphite, ceramic, and steel, which can withstand high temperatures and pressure. They are also coated with special materials that prevent oxidation, corrosion, and buildup, which can affect the quality of the connection. The molds are designed to be reusable, with easy-to-replace parts, saving customers time and money in the long run.In addition to producing molds, the company also offers training and support services to customers, ensuring they can operate the equipment safely and efficiently. They have a team of experts with extensive knowledge and experience in exothermic welding who can provide technical support, advice, and troubleshooting. They also offer custom machining services to meet specific customer requirements.The company's dedication to quality, innovation, and customer service has earned them a reputation as one of the leading manufacturers of exothermic welding molds in the industry. They have a vast network of distributors and partners in different countries, who can provide local support and services. They are also committed to sustainability, minimizing their environmental impact, and promoting social responsibility.In conclusion, exothermic welding is an essential process in the industrial sector, and the quality of the molds used plays a crucial role in the final results. The company described above is a leader in this field, producing high-quality exothermic welding molds that meet the most stringent standards. Their molds are designed to be durable, reliable, and easy to use, with excellent support and training services. As the demand for exothermic welding grows, this company is well-positioned to continue providing innovative solutions for their customers' needs.

High-Quality Homemade Graphite Crucible for Various Applications

Homemade Graphite Crucible Revolutionizes the Foundry IndustryIn the world of metal casting, the crucible is an essential component that plays a critical role in the process of melting and pouring metals such as iron, steel, aluminum, and bronze. Traditionally, crucibles were manufactured using clay, silicon carbide, and other refractory materials, but recently, a new player has emerged in the foundry industry – a homemade graphite crucible that is revolutionizing the way metals are cast.The graphite crucible, created by a small, innovative company, has been making waves in the industry due to its unique properties and superior performance. Unlike traditional crucibles, which are often prone to cracking and have limited durability, the homemade graphite crucible offers exceptional thermal stability and resistance to thermal shock. This makes it an ideal choice for foundries looking to improve their casting processes and enhance the quality of their metal products.One of the key advantages of the homemade graphite crucible is its ability to withstand extreme temperatures, making it suitable for use with a wide range of metals and alloys. Its high thermal conductivity allows for rapid and uniform heating, ensuring efficient melting and pouring of metals. Additionally, the graphite material offers excellent chemical inertness, preventing the crucible from reacting with the molten metal and contaminating the final product.Furthermore, the homemade graphite crucible has proven to be highly durable and long-lasting, providing foundries with a cost-effective solution for their casting needs. Unlike traditional crucibles that require frequent replacement due to wear and tear, the graphite crucible can withstand prolonged use without compromising its performance. This not only reduces maintenance and replacement costs but also minimizes downtime, allowing foundries to maximize their productivity and output.In addition to its technical advantages, the homemade graphite crucible is also environmentally friendly. The production process of the crucible involves minimal waste and energy consumption, making it a sustainable option for foundries looking to reduce their environmental footprint. Furthermore, the crucible can be recycled after use, further minimizing its impact on the environment.The company behind the homemade graphite crucible takes pride in its commitment to innovation and quality. With a team of experienced engineers and metallurgists, the company has developed a range of graphite crucibles that are tailored to meet the specific needs of different foundries. Whether it's a small-scale operation or a large industrial foundry, the company offers custom solutions that are designed to maximize performance and efficiency.The success of the homemade graphite crucible has caught the attention of industry leaders and experts, who recognize its potential to transform the foundry industry. In a recent interview, the CEO of a leading foundry remarked, "The homemade graphite crucible has been a game-changer for our operation. It has significantly improved our casting processes, resulting in higher-quality products and increased efficiency."As the demand for high-quality metal products continues to grow, the homemade graphite crucible is poised to play a pivotal role in shaping the future of the foundry industry. Its unique combination of performance, durability, and sustainability has positioned it as a top choice for foundries seeking to stay ahead of the competition.In conclusion, the homemade graphite crucible has emerged as a disruptive force in the foundry industry, offering a new and improved alternative to traditional crucibles. With its superior performance, durability, and environmental benefits, the graphite crucible is set to revolutionize the way metals are cast, paving the way for a more efficient and sustainable future for foundries around the world.

Graphite Container for Hard Alloy: An Essential Tool for Industrial Applications

Graphite Container For Hard Alloy, a leading manufacturer in the field of graphite products, has introduced a new and innovative solution for the production of hard alloy tools. This breakthrough technology is set to revolutionize the hard alloy industry by providing a more efficient and cost-effective method for manufacturing high-quality tools.The company, which has been in operation for over 20 years, has a long-standing reputation for producing top-notch graphite products for various industries, including metallurgy, electronics, and chemicals. With their team of experienced engineers and state-of-the-art manufacturing facilities, Graphite Container For Hard Alloy has become a trusted partner for businesses in need of high-quality graphite products.The new graphite container for hard alloy is designed to address the challenges faced by manufacturers in producing hard alloy tools. Traditionally, the production process for hard alloy tools involves melting and sintering the raw materials in a graphite container. However, this method often results in high production costs and long processing times, making it inefficient for large-scale production.Recognizing the need for a more efficient solution, Graphite Container For Hard Alloy has developed a unique graphite container that offers superior thermal stability and resistance to chemical corrosion. This innovative design allows for faster and more uniform heating of the raw materials, resulting in shorter processing times and lower energy consumption.In addition to improving production efficiency, the new graphite container also delivers enhanced performance and durability for hard alloy tools. The high thermal stability of the graphite material ensures consistent processing temperatures, leading to improved material properties and higher tool quality. Furthermore, the container's resistance to chemical corrosion prevents contamination of the hard alloy, resulting in a longer lifespan for the tools."The introduction of our new graphite container for hard alloy is a game-changer for the industry," said the CEO of Graphite Container For Hard Alloy. "We have harnessed our expertise in graphite technology to develop a solution that not only improves production efficiency but also enhances the quality and durability of hard alloy tools. We are confident that this innovation will set new standards in the hard alloy industry and bring significant benefits to manufacturers."The launch of the new graphite container has already garnered significant interest from companies in the hard alloy industry. Several leading manufacturers have expressed their eagerness to adopt the new technology, citing its potential to streamline their production processes and improve the quality of their products. Graphite Container For Hard Alloy is currently in discussions with these companies to implement the new graphite container into their production lines.In conclusion, Graphite Container For Hard Alloy has once again demonstrated its commitment to innovation and excellence with the introduction of the new graphite container for hard alloy. This breakthrough technology is poised to transform the hard alloy industry by offering a more efficient, cost-effective, and high-quality solution for tool manufacturing. As the company continues to work closely with industry partners to implement the new technology, it is expected to bring significant advancements to the production of hard alloy tools.

Discover the Latest Innovation in Sustainable Energy: Carbon Felt Technology

Carbon Felt: An Innovative Solution for High Performance ApplicationsIn today's world, where energy conservation, efficiency and reducing carbon emissions are of utmost importance, Carbon Felt is gaining popularity as an innovative solution for high-performance applications. Carbon Felt has the potential to revolutionize numerous industries, by providing a reliable, cost-effective and sustainable source of energy. It is a preferable alternative to traditional energy sources, such as fossil fuels, due to its numerous benefits and excellent properties.Carbon Felt is a polymer-based material with electrical conductivity. It is made up of carbon fibers which are intertwined and piled on top of each other to form a soft and flexible felt-like substance. Carbon Felt has a multitude of applications such as fuel cells, batteries, industrial heating, protective clothing, and automotive applications.The use of Carbon Felt has gained increased popularity in recent years due to the exceptional properties of this material like low thermal conductivity, excellent corrosion resistance and high thermal stability. It is capable of withstanding extreme temperatures, making it an ideal candidate for high-performance applications.One of the most significant advantages of Carbon Felt is its use in fuel cells. Fuel cells are the future of clean energy, and Carbon Felt plays a critical role in its development. Fuel cells are an electrochemical device that convert chemical energy into electrical energy and produce minimal emissions during the process. Carbon Felt acts as the electrode in fuel cells, meaning it connects the fuel system, catalyst, and electrolyte. The use of Carbon Felt results in reduced production costs, optimization of fuel cells, and a better performance.Carbon Felt is also used extensively in the manufacture of high-performance batteries for electric and hybrid vehicles. Carbon Felt is used as a separator in Lithium-ion batteries in conjunction with positive and negative electrodes. The separator plays a critical role in preventing shorts between the electrodes and allows the flow of ionic conductive electrolytes, which in turn generates an electrical current. The use of Carbon Felt in batteries enhances their performance, lowers costs, and makes them more efficient.Another important application for Carbon Felt is in industrial heating. Carbon Felt has excellent char-forming abilities, making it an ideal material for insulation. The thermal conductivity of this material is low, making it an excellent insulator. In industrial heating applications, Carbon Felt provides efficient insulation, reduces production costs, and enhances the efficiency of the heating application.Protective clothing manufacturers also use Carbon Felt in their products. When combined with other materials, it forms a highly effective barrier against hazardous chemicals and flames. Carbon Felt provides exceptional protection against heat and fire, making it an ideal material for applications like firefighter suits and protective clothing for chemical workers.Finally, Carbon Felt has applications in the automotive industry, particularly in the exhaust system. Carbon Felt filters the pollutants from the exhaust gases, making them less harmful to the environment. This material is also used as a catalyst support, which helps in the reduction of emissions from the exhaust gases.Carbon Felt is not only an innovative material but is also highly sustainable, making it a great alternative to traditional energy sources. Being made up of carbon, which is a naturally occurring element, it is not harmful to the environment and can be recycled for future use.The company, at the cutting-edge of the development and manufacture of Carbon Felt, has established itself as a leading player in the industry. The company's state-of-the-art manufacturing facilities and research units ensure the development and production of top-quality products.The company specializes in the manufacture of Carbon Felt products, with each product designed to serve a specific purpose. They use high-quality raw materials and are committed to delivering customer satisfaction. The company's products are extensively tested and quality-certified, ensuring that each product is of the highest standard.In conclusion, the use of Carbon Felt is a game-changer in numerous industries. This innovative material offers exceptional performance, cost-effectiveness, and sustainability, making it an essential player in the world's quest for clean energy. The company at the forefront of Carbon Felt's development and manufacture is well-positioned to take advantage of these benefits, and we can expect to see a great deal more of this material in the future.

Discover the Latest Graphite Foundry Crucible Innovations in China

Title: China's Foundry Crucibles Forge New Path for Global IndustryIntroduction:China's graphite foundry crucibles have emerged as a revolutionary force within the global foundry industry. These crucibles, manufactured using cutting-edge technology, have redefined standards of quality, durability, and performance. With a strong commitment to innovation and excellence, Chinese manufacturers are leading the way in providing essential tools for the metalcasting sector worldwide. In this article, we explore how China's graphite foundry crucibles are revolutionizing the industry and propelling it towards a brighter future.1. Background:The foundry industry is crucial for manufacturing various metal parts and components, making it a significant contributor to global economic development. Foundry crucibles play a vital role in this process, serving as containers for melting and casting materials, including steel, aluminum, iron, and other metals. Crucibles require exceptional heat resistance, chemical stability, and robustness to withstand the extreme conditions of metalcasting processes.2. Chinese Crucibles: Transforming the Industry:China's graphite foundry crucibles have garnered attention worldwide due to their impeccable performance and ability to surpass international quality standards. Through continuous research and development, Chinese manufacturers have developed crucibles that offer superior heat resistance, optimal thermal conductivity, and excellent resistance to chemical reactions, resulting in improved casting efficiency.3. Technological Advancements:China's graphite foundry crucibles owe their superiority to state-of-the-art manufacturing processes and advanced materials. These crucibles are typically manufactured using purified graphite, which possesses remarkable properties such as high temperature resistance, low thermal expansion, and excellent heat distribution capabilities. Innovative shaping techniques and carbon bonding further enhance crucible strength, ensuring longevity and minimizing downtime for foundries.4. Durability and Reliability:Chinese graphite foundry crucibles are renowned for their exceptional durability and reliability, reducing the need for frequent crucible replacements. The robustness of these crucibles enables foundries to work continuously without interruptions, resulting in enhanced production output and cost-effectiveness. Moreover, the impressive longevity of Chinese crucibles significantly reduces waste, making them an environmentally-friendly choice.5. Global Impact and Market Reach:The reliability, durability, and cost-effectiveness of Chinese graphite foundry crucibles have led to increased adoption by foundries worldwide. China's crucibles have effectively bridged the technological gap that previously existed in the market, providing foundries of all scales with high-quality, affordable options. As a result, manufacturers globally are benefitting from improved casting precision, increased production efficiency, and reduced operational costs.6. Industry Transformation and Growth:The emergence of China's graphite foundry crucibles has triggered a transformation within the global foundry industry. Foundries that previously faced substantial challenges, such as inadequate crucible performance, are now witnessing enhanced operational efficiency, elevated casting precision, and reduced downtime. This revolution has not only strengthened the competitiveness of Chinese manufacturers but has also paved the way for unprecedented growth of the entire metalcasting sector worldwide.Conclusion:China's graphite foundry crucibles have reinvigorated the global foundry industry, revolutionizing casting processes with their superior quality, durability, and reliability. Through advanced technology and constant innovation, Chinese manufacturers have set new standards, enabling foundries to achieve higher levels of productivity, efficiency, and cost-effectiveness. As the industry continues to embrace China's crucibles, the future looks promising, with metalcasting operations projected to reach new heights of excellence across the globe.

Top Graphite Products Supplier: Delivering High-Quality Industrial Solutions

Graphite Products Supplier Expands Offerings to Meet Growing Market Demand[City, Date] - Graphite Products Supplier, a leading provider of high-quality graphite products, has announced a significant expansion of its product offerings to meet the growing market demand. With a strong commitment to excellence and a focus on delivering superior products, the company aims to cater to a wide range of industries that rely on graphite components.Graphite is a versatile material known for its unique properties, making it highly valuable in various industries such as aerospace, automotive, electronics, and energy. Its excellent thermal and electrical conductivity, along with its high strength and low weight, makes it an ideal choice for manufacturing various essential components.With a proven track record of delivering exceptional graphite solutions, Graphite Product Supplier has established itself as a reliable partner to companies across different sectors. The company provides a wide range of graphite products, including graphite rods, tubes, plates, and machined parts, to meet diverse industrial needs.The recent expansion of the company's product offerings is driven by the growing market demand for graphite components and the need to cater to various custom requirements. By adding new products to its portfolio, Graphite Products Supplier aims to better serve its existing customers while also attracting new clients seeking high-quality graphite solutions.The company's extensive research and development efforts have enabled them to develop advanced graphite products that are at the forefront of technological innovation. With state-of-the-art manufacturing facilities and a team of experienced professionals, Graphite Products Supplier ensures that its products adhere to the highest quality standards.One of the key highlights of the expanded product line is the introduction of enhanced graphite electrodes. These electrodes are widely utilized in electric arc furnaces for steel production and are critical in maintaining high efficiency and quality in the steelmaking process. The advanced properties of these graphite electrodes, such as high thermal conductivity and low electrical resistance, contribute to improved productivity and cost-effectiveness for steel manufacturers.Furthermore, the company is also introducing high-performance graphite crucibles, which are essential in various industrial applications such as metal casting, chemical analysis, and melting processes. With superior thermal stability and resistance to chemical corrosion, these crucibles ensure efficient and reliable operations in demanding environments.Graphite Products Supplier remains committed to sustainable practices, both in terms of product development and manufacturing processes. The company emphasizes using eco-friendly materials and implementing energy-efficient techniques to minimize its environmental impact. By incorporating sustainable practices throughout its operations, Graphite Products Supplier strives to create a positive and responsible impact on the planet.To support this expansion and meet the increased demand for its products, Graphite Products Supplier plans to further invest in research and development capabilities as well as production capacity. These initiatives will contribute to driving innovation, improving product performance, and maintaining a competitive edge in the market.With its expanded product offerings and a continued focus on customer satisfaction, Graphite Products Supplier is well-positioned to meet the evolving needs of various industries that rely on high-quality graphite components. The company's commitment to excellence, sustainability, and technological advancement ensures that it remains a trusted partner for companies seeking reliable graphite solutions.About Graphite Products Supplier:Graphite Products Supplier is a leading provider of high-quality graphite products, serving a wide range of industries globally. With a strong commitment to excellence and sustainability, the company delivers cutting-edge graphite components that meet the unique needs of its clients. Through continuous research and development efforts, Graphite Products Supplier remains at the forefront of technological innovation and aims to provide superior solutions to its customers.Contact:[Company Name][Contact Person][Address][Phone][Email][Website]

Unlocking the Potential of Special Graphite: A Game Changer in Industrial Applications

Special Graphite: A Game-Changer in Advanced IndustriesIn the ever-evolving world of advanced materials, Special Graphite has emerged as a key player, revolutionizing various industries with its exceptional properties and unparalleled performance. With an extensive range of applications and a strong focus on innovation, Special Graphite has positioned itself as a game-changer in the world of advanced industries.Founded in [], Special Graphite has quickly gained prominence as a leading manufacturer and supplier of premium-quality graphite products. Committed to delivering excellence, the company has set the benchmark for superior quality, reliability, and customer satisfaction.The success of Special Graphite can be attributed to its state-of-the-art manufacturing facilities, where cutting-edge technology and advanced production techniques are employed. The company's world-class research and development team consistently strive to develop innovative solutions that meet the ever-evolving needs of its customers. By combining their expertise in materials science and engineering, they have been able to create a diverse portfolio of graphite products that cater to a wide range of industries.One of the key strengths of Special Graphite lies in its ability to customize its products according to customer requirements. Whether it's a complex-shaped component or a specific composition, the company's manufacturing capabilities allow for the production of tailor-made solutions. This flexibility has earned Special Graphite a reputation for being a reliable partner, capable of meeting the most demanding specifications.The versatility of Special Graphite is evident in its application across various industries. In the electronics industry, Special Graphite is widely used for the production of components such as crucibles, heating elements, and electrodes. Its excellent thermal stability, high electrical conductivity, and low thermal expansion make it an ideal choice for these critical applications.In the automotive sector, Special Graphite plays a pivotal role in the manufacturing of lithium-ion batteries, fuel cells, and brake systems. With the increasing demand for electric vehicles, the need for high-performance graphite materials has surged. Special Graphite's products meet these requirements, enabling the automotive industry to move towards a sustainable future.The aerospace industry also benefits greatly from Special Graphite's capabilities. Its lightweight yet robust nature, coupled with its resistance to high temperatures and corrosive environments, makes it an indispensable material for aircraft components, satellite systems, and rocket propulsion. The reliability and performance of Special Graphite have been crucial in ensuring the safety and efficiency of aerospace operations.Moreover, Special Graphite has made significant contributions to the metallurgical industry, where its products find applications in the production of steel, aluminum, and other metals. The unique properties of Special Graphite, such as its high thermal conductivity and low friction coefficient, enhance the efficiency of these processes, resulting in higher productivity and cost savings for manufacturers.In addition to its wide range of applications, Special Graphite places a strong emphasis on sustainability. The company recognizes the importance of minimizing its environmental impact and actively pursues eco-friendly practices throughout its operations. By focusing on energy efficiency, waste reduction, and responsible sourcing of raw materials, Special Graphite acts as a responsible corporate citizen, contributing towards a more sustainable future.In conclusion, Special Graphite has emerged as a major player in the advanced materials industry, earning a reputation for its exceptional products and commitment to innovation. With its focus on customization, versatility, and sustainability, the company has successfully revolutionized several industries, including electronics, automotive, aerospace, and metallurgy. As the demand for high-performance materials continues to rise, Special Graphite remains at the forefront, driving advancements and enabling progress in advanced industries worldwide.

Discover the Advantages of Isostatic Graphite in Various Industries

Title: Exploring the Advancements of Isostatic Graphite: A Leading Edge Material for Multiple IndustriesIntroduction:Isostatic graphite, an innovative and exceptional material, has been gaining significant attention due to its remarkable properties and versatile applications across various industries. Companies such as (brand name) have been at the forefront of producing high-quality isostatic graphite to cater to the evolving demands of sectors ranging from metallurgy and electronics to aerospace and automotive. This news article aims to delve into the properties, applications, and latest advancements surrounding isostatic graphite, while also highlighting the company's leading role in this field.Properties of Isostatic Graphite:Isostatic graphite is a unique type of graphite manufactured through a specialized process called isostatic pressing. This technology ensures uniformity in density and structure, resulting in superior quality graphite with exceptional mechanical, thermal, and electrical properties.1. Mechanical Properties: Isostatic graphite exhibits high strength, stiffness, and resistance to wear, making it ideal for applications requiring dimensional stability and durability.2. Thermal Properties: With an excellent thermal conductivity, low thermal expansion, and resistance to thermal shock, isostatic graphite finds extensive use in high-temperature applications like heat exchangers, crucibles, and radiant tubes.3. Electrical Properties: Isostatic graphite possesses high electrical conductivity, making it suitable for use in electric arc furnaces, electrodes, and numerous electrical components.Applications of Isostatic Graphite:The unique combination of properties offered by isostatic graphite allows for a wide range of applications across diverse industries:1. Metallurgy: Isostatic graphite is commonly utilized in the production of crucibles, molds, and tanks used in the manufacturing of non-ferrous metals, such as copper and aluminum.2. Electronics: As a critical component in electric discharge machining (EDM), isostatic graphite enables precise and efficient machining of complex shapes in the electronics industry.3. Semiconductor Industry: Isostatic graphite plays a pivotal role in the production of silicon wafers for semiconductor manufacturing, as it provides an excellent surface quality and thermal stability required for advanced microchip fabrication.4. Aerospace and Automotive: Isostatic graphite's lightweight nature, high strength, and resistance to extreme temperatures have made it indispensable in aerospace applications, including rocket nozzles, aircraft brakes, and satellite components. Additionally, it finds use in automotive parts, such as clutch discs and cylinder head gaskets.5. Solar Energy: The solar industry benefits from isostatic graphite in the form of high-purity graphite components used in solar panels, ensuring efficient solar energy conversion.6. Medical and Pharmaceutical: Isostatic graphite serves in various medical applications, such as prosthetic limbs, heart valves, and surgical instruments due to its biocompatibility, thermal resistance, and mechanical strength.The Innovations of (Company Name):(Company Name), a distinguished leader in the manufacturing of isostatic graphite, has continuously revolutionized this industry through ongoing research, development, and technological advancements.1. Cutting-edge Production Techniques: (Company Name) employs state-of-the-art isostatic pressing technology to produce isostatic graphite with exceptional density, homogeneity, and purity, ensuring consistent quality and reliability.2. Customized Solutions: Understanding the unique requirements of different sectors, (Company Name) offers tailored isostatic graphite solutions, collaborating closely with clients to develop innovative graphite materials suited to their specific needs.3. Sustainability Initiatives: (Company Name) recognizes the importance of sustainable manufacturing, hence ensures responsible sourcing of raw materials and implements environmentally friendly practices throughout its production processes.Collaborative Ventures and the Future:In addition to its exemplary production capabilities, (Company Name) actively engages in collaborative ventures with research institutions, universities, and industry experts to further explore the potential applications and advancements of isostatic graphite. This commitment to research and development is expected to drive the material's continued growth and enhance its capabilities in emerging industries such as renewable energy storage, special coatings, and advanced composites.Conclusion:Isostatic graphite has emerged as a groundbreaking material, reshaping industries through its remarkable properties and diverse applications. Companies like (Company Name) have played a crucial role in fueling the advancements of isostatic graphite, ensuring its availability and efficacy in meeting the evolving needs of various sectors. As research and innovations continue to enhance its capabilities, isostatic graphite holds tremendous potential for shaping a more sustainable and technologically advanced future across multiple industries.

Experts Share Tips on Making Graphite Molds for Precision Manufacturing

Vancouver, Canada - A leading graphite mold manufacturer has announced a new addition to its product line that promises to further solidify its position as a top player in the industry. The company, which specializes in producing high-quality graphite molds, has unveiled its latest product offerings that are geared towards providing customers with even more options for their applications.Graphite molds are an essential part of the manufacturing process for a wide range of industries, including the automotive, aerospace, and medical industries. They are used to create intricate and precise shapes, as well as the replication of complex designs. The company's graphite molds have long been known for their durability, strength, and precision, making them a favorite among industry professionals and manufacturers.The addition of these new products is set to broaden the company's reach and enhance its offerings to customers. The company has always been at the forefront of innovation in the industry, constantly adapting to new technologies and trends to stay ahead of the competition. The new graphite molds are no different, with a focus on precision, accuracy, and quality."Our new products are designed with our customers in mind," said the company spokesperson. "We understand that each client has unique needs, and our goal is to provide them with the best possible solutions to meet their requirements. We are confident that our new graphite molds will do just that."The new graphite molds come in a variety of shapes and sizes, making them suitable for different applications. The company has ensured that every mold meets the strictest quality standards to ensure maximum efficiency and effectiveness during the manufacturing process.Besides the quality and precision of the molds, the company has always placed great emphasis on customer service. In a highly competitive industry, customer satisfaction is crucial, and the company is well aware of that. The company spokesperson added that "our customers are at the heart of everything we do. We strive to exceed their expectations by providing them with the best products and services possible."The company's commitment to excellence has earned them a reputation as a dependable and trustworthy partner in the industry. They have worked with some of the biggest names in the business and have consistently delivered quality products and services that meet the client's needs."We are proud of our heritage and our contribution to the industry," said the spokesperson. "Our goal is to continue to build on that legacy and remain at the forefront of innovation in the graphite mold industry."With the unveiling of these new products, the company looks set to continue to dominate the industry and cement its position as a top manufacturer of graphite molds. The company's growth is a testament to its commitment to quality, innovation, and customer service, values that have earned it a loyal customer base and a reputation as a leading player in the industry. For customers looking for a reliable and high-quality graphite mold supplier, this company is worth considering. With its impressive track record, a focus on product innovation, and unmatched customer service, they are a dependable partner for manufacturing businesses of all sizes.