Discover the Incredible Properties of a Graphite Cylinder for Industrial Applications

By:Admin

Introduction:

Graphite cylinder technology is set to revolutionize various industries, paving the way for enhanced efficiency, durability, and sustainability. This groundbreaking innovation, conceived and developed by a leading company in the field, holds immense potential for advancements in sectors such as energy storage, automotive, aerospace, and renewable energy. This article delves into the characteristics of this remarkable graphite cylinder and explores its wide-ranging applications.

1. Unveiling the Graphite Cylinder:

The graphite cylinder, meticulously engineered by industry experts, is a cylindrical structure composed of high-quality graphite materials. Its production involves a precise and complex manufacturing process, resulting in an exceptionally robust and versatile end product. The material properties of this invention make it an ideal choice for applications requiring high thermal and electrical conductivity, low friction, and excellent resistance to corrosion and wear.

2. Advancements in Energy Storage:

Energy storage solutions are critical for a sustainable future, and the graphite cylinder emerges as a game-changer in this domain. By integrating advanced graphitic technology into battery systems, the cylindrical design facilitates higher energy density, faster charging, and longer lifespan. These improvements are set to significantly impact electric vehicles, portable electronics, and grid-scale storage systems, enabling cleaner and more efficient energy storage solutions.

3. Automotive Evolution:

With the automotive industry rapidly transitioning towards electrification, the graphite cylinder presents a significant breakthrough. By integrating this technology into electric vehicle battery packs, manufacturers can enhance energy density, increase charging speed, and improve overall performance. These advancements will not only extend the distance electric vehicles can travel but also reduce charging times, making them more practical and convenient for the masses.

4. Aerospace Innovations:

Graphite cylinder technology is poised to revolutionize the aerospace industry by enhancing the performance and durability of various components. With its exceptional thermal conductivity and lightweight characteristics, the graphite cylinder can be utilized in heat transfer systems, reducing weight and enhancing fuel efficiency. Additionally, its high resistance to corrosion and wear make it an ideal material for various aircraft components, ensuring longevity and safety.

5. Renewable Energy Solutions:

Renewable energy sources such as wind and solar are seeing rapid growth worldwide. However, efficient storage systems for such renewable energy are often limited. The graphite cylinder's ability to enhance energy storage can remarkably improve the viability and reliability of renewable energy projects. By harnessing the cylinder's power, the energy generated from these sources can be efficiently stored and supplied on-demand, minimizing wastage and maximizing utilization.

6. Environmental Sustainability:

Integrating the graphite cylinder into different sectors discussed above not only improves performance but also promotes environmental sustainability. By enabling clean energy storage, the technology reduces reliance on fossil fuels, thus reducing greenhouse gas emissions. Moreover, the longer lifespan and durability of batteries incorporating the graphite cylinder also contribute to reducing electronic waste, making it an eco-friendly choice across industries.

Conclusion:

The graphite cylinder, created by {Company Name}'s cutting-edge research and development, holds immense promise for multiple industries. Its ability to enhance energy storage, improve automotive capabilities, revolutionize aerospace components, and bolster renewable energy projects positions it as a transformative innovation. As industries seek sustainable solutions and improved performance, the graphite cylinder emerges as a frontrunner, poised to shape the future of technology and usher in an era of enhanced efficiency and sustainability.

Company News & Blog

Isostatic Graphite Industry: Growth, Usage, and Properties – Global & China Insights, 2018-2022

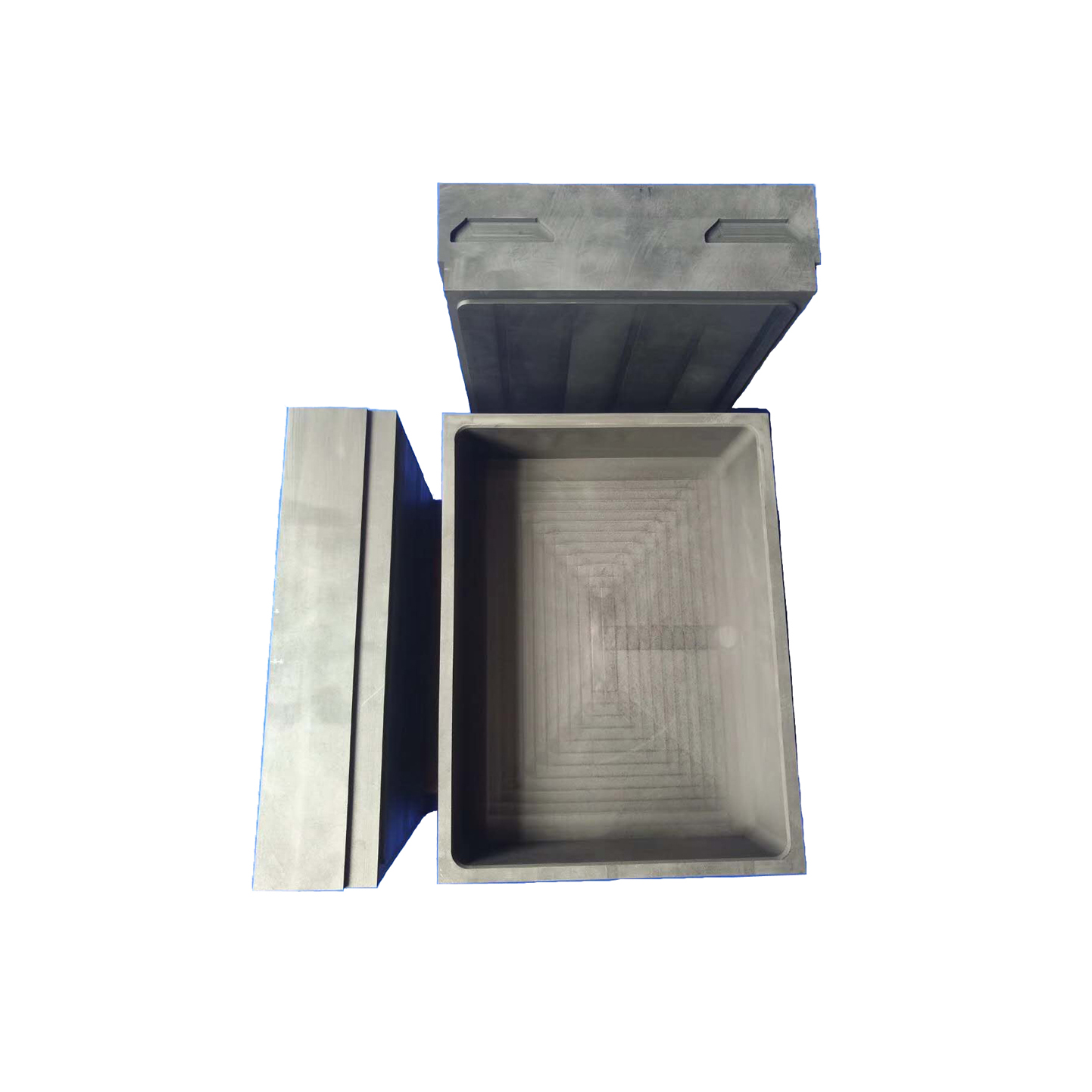

Isostatic graphite: The specialty graphite with exceptional propertiesIsostatic graphite, also known as molded graphite, is a type of high-end specialty graphite that has multiple exceptional properties. It differs from other types of graphite, as it is produced by isostatic pressing of graphite particles instead of the traditional extrusion or compression processes.The resulting material has a unique microstructure that gives it unmatched mechanical strength, high thermal conductivity, low thermal expansion coefficient, excellent electrical conductivity, and chemical inertness. Therefore, isostatic graphite has numerous applications across different industries, such as aerospace, semiconductor, nuclear, and metallurgy, among others.China is one of the leading producers and consumers of isostatic graphite, with a significant increase in demand over the last few years. The country has abundant graphite resources and advanced technologies to produce high-quality isostatic graphite, which is widely used for manufacturing graphite electrodes, crucibles, molds, and heating elements.China Isostatic Graphite Pot: The Innovative Solution for High-Temperature ApplicationsThe China Isostatic Graphite Pot is a new and innovative product that is made from high-quality isostatic graphite and has excellent performance in high-temperature applications. The pot is specially designed to withstand extreme temperatures and harsh chemical environments, making it the perfect solution for various industrial processes.One of the main advantages of the China Isostatic Graphite Pot is its ability to resist thermal shock and oxidation, which is critical in applications involving the melting and casting of metals and alloys. Its superior thermal stability also means that it can maintain its structural integrity and dimensional accuracy over a wide range of temperatures, even up to 3000°C.Moreover, the China Isostatic Graphite Pot has a low porosity and high density, which enables it to have excellent mechanical strength and wear resistance. It is also chemically inert, ensuring that it does not contaminate the molten metal or alloy during the casting process.Applications of China Isostatic Graphite PotThe China Isostatic Graphite Pot has numerous applications in different industries, including:1. Metallurgy: The pot is used for melting and casting various metals and alloys, such as steel, iron, copper, aluminum, and titanium, among others.2. Semiconductor: The pot is used for growing single crystals of silicon and other semiconductors, which are used in electronic devices.3. Aerospace: The pot is used for manufacturing rocket nozzles, heat shields, and other components that require high-temperature resistance.4. Chemical: The pot is used for carrying out chemical reactions that involve high temperatures and harsh chemicals.ConclusionIsostatic graphite is a unique and valuable material that has numerous applications across different industries. The China Isostatic Graphite Pot is a new and innovative solution that offers exceptional performance in high-temperature applications, especially in the metallurgy, semiconductor, aerospace, and chemical industries. With its superior thermal stability, mechanical strength, and chemical inertness, the China Isostatic Graphite Pot is an excellent investment for any industrial process that requires high-temperature resistance and dimensional accuracy.

How the World's First Graphite Heater is Revolutionizing Heating Systems" can be rewritten as "Discovering the Revolutionary Advantages of Graphite Heaters in Modern Heating Systems".

Graphite Heater Innovations Set to Revolutionize Heating TechnologyGraphite Heater Innovations (GHI) is a leading technology company specializing in the design and manufacture of state-of-the-art graphite heaters. The company prides itself in its ability to produce high-quality products that are energy-efficient, cost-effective, and environmentally friendly.GHI has been in operation for more than a decade and has amassed a wealth of experience in the field of heating technology. The company is committed to developing innovative products that meet the needs of commercial and industrial customers. Its products are used in a wide range of applications, including metallurgy, semiconductor manufacturing, chemical processing, and automotive production, among others.One of the company's most significant breakthroughs is the development of the Graphite Heater. The Graphite Heater is a unique heating element that can be customized to meet the specific needs of each customer. The heater is made from high-quality graphite and uses advanced technology to provide precise heating control. It is designed to be energy-efficient, which means it consumes less power compared to traditional heating systems. The result is a reduction in energy costs and an increase in overall productivity.The Graphite Heater is also environmentally friendly, as it produces lower emissions compared to other heating systems. It is designed to have a long lifespan, ensuring that customers can benefit from its efficiency and effectiveness for many years to come. The heater is easy to install and maintain, with minimal downtime required.GHI's innovative heaters have gained a reputation for their high quality, reliability, and efficiency. The company's team of experts works closely with its customers to ensure that they get the most out of their heating system. GHI offers a range of services, including technical support, maintenance, and repair, to ensure that its customers' needs are met promptly and efficiently.One of the company's recent projects involved the design and development of a heating system for a semiconductor manufacturing plant. The plant required a heating system that could provide a stable and precise temperature control to ensure the success of the manufacturing process. GHI was able to design a custom Graphite Heater that met the plant's specific needs, resulting in improved productivity and reduced energy costs.GHI has also been working with the automotive industry, developing heating systems for car parts. The company's heat technology has been used in the production of catalytic converters, which are essential in reducing the emissions from vehicles. GHI's Graphite Heater was chosen as it is energy-efficient and produces low emissions, making it an ideal solution for the automotive industry.In conclusion, Graphite Heater Innovations is a leading technology company that is revolutionizing the heating industry. Its innovative and energy-efficient products are changing the way that businesses approach heating, resulting in reduced costs, increased productivity, and improved environmental sustainability. With its commitment to quality and customer satisfaction, GHI is poised to continue leading the way in heating technology for many years to come.

New Graphite Heating Rods Revolutionize Electrical Heating Technology

Title: Breakthrough Graphite Heating Rods Revolutionize the Heating IndustryIntroduction:With a relentless commitment to innovation, [Brand Name] has made a groundbreaking leap forward in the heating industry. The company's latest product, advanced graphite heating rods, promises to redefine the efficiency and effectiveness of heating systems in various applications. By combining cutting-edge technology with their expertise, [Brand Name] has once again established itself as a leader in the field. This article will provide an in-depth analysis of the features, benefits, and potential impact of these remarkable heating rods.Section 1: Background and SignificanceThe demand for heating systems that offer higher energy efficiency and reduced environmental impact has been increasing rapidly. Traditional heating methods, such as gas and electric furnaces, have limitations in terms of energy consumption and heat transfer efficiency. Recognizing this, [Brand Name] invested substantial resources in research and development to create graphite heating rods that would address these challenges.Section 2: Graphite Heating Rods: The Technology Behind the InnovationGraphite heating rods consist of advanced graphite materials that possess excellent thermal and electrical conductivity properties, making them ideal for heating applications. These rods have high resistance to extreme temperatures and provide even heat distribution, enabling them to heat up spaces quickly and efficiently. With a sleek and compact design, these rods offer superior durability and longevity, saving users from frequent replacements and repair costs.Section 3: Advantages and Benefits3.1 Energy Efficiency and Cost SavingsThe use of graphite heating rods significantly enhances energy efficiency, allowing users to lower energy consumption and ultimately reduce utility bills. With their remarkable heat conductivity, these heating rods eliminate heat loss during distribution, ensuring that the desired space is heated promptly, with no wasted energy.3.2 Rapid Heating and Enhanced ComfortGraphite heating rods heat up rapidly, reducing warm-up times considerably. This feature is particularly beneficial in industrial applications, where fast and efficient heating is crucial. Additionally, the remarkable heat distribution provided by these rods ensures that every corner of a room receives even warmth, providing optimal comfort to occupants.3.3 Environmental FriendlinessCompared to traditional heating methods, graphite heating rods produce minimal greenhouse gas emissions. By harnessing clean and renewable energy sources, such as electricity generated from solar or wind power, these rods contribute to a greener and more sustainable future.Section 4: Wide Range of ApplicationsGraphite heating rods offer a wide range of applications across different industries and settings. They are suitable for residential heating needs, commercial spaces like offices, hospitals, and shopping centers, as well as industrial processes where fast and precise heating is required. From homes to factories, the versatility and efficiency of these rods make them an ideal choice for any heating purpose.Section 5: The Future of Heating SystemsThe introduction of graphite heating rods marks a significant milestone in the heating industry. Its innovative design, energy efficiency, and environmental benefits position it as a promising alternative to traditional methods. The potential widespread adoption of these rods could revolutionize the heating industry, presenting a cleaner and more sustainable way to keep spaces warm.Conclusion:[Brand Name]'s graphite heating rods serve as a testament to their commitment to pushing the boundaries of innovation in the heating industry. With their exceptional thermal conductivity, energy efficiency, and environmental friendliness, these rods pave the way for a more sustainable and cost-effective heating solution. As the world continues to search for greener alternatives, [Brand Name]'s graphite heating rods offer a glimpse into the future of heating systems.

Revolutionary Graphite Heating Furnace: A Game-Changer in the Industry

Title: Innovative Graphite Heating Furnace Revolutionizes Industrial Heating ProcessesIntroduction:Graphite Heating Furnace, a groundbreaking industrial heating solution, is transforming the way various industries achieve their heating requirements. Developed by a pioneering and technologically advanced company, this graphite-based furnace offers unparalleled efficiency, versatility, and sustainability. This revolutionary heating system optimizes energy usage while reducing environmental impact, making it an ideal choice for industries worldwide.Incorporating Advanced Graphite Technology:The cutting-edge graphite technology employed in this advanced heating furnace is a testament to the relentless pursuit of innovation by the company. By utilizing the unique properties of graphite, this heating system delivers exceptional performance in terms of heat transfer, temperature uniformity, and overall energy efficiency.Unmatched Efficiency and Versatility:The Graphite Heating Furnace is versatile enough to cater to a wide array of industries, including aerospace, automotive, electronics, and metallurgy. Its customizability allows for precise temperature control, ensuring an optimized environment for various heating processes such as annealing, sintering, brazing, and tempering. With outstanding uniformity throughout the working space, it guarantees consistent and quality results every time.Enhanced Productivity and Cost-effectiveness:Equipped with the latest automation technologies and intelligent control systems, the Graphite Heating Furnace improves production efficiency and streamlines operations. Its advanced features, including programmable heating profiles, automatic heat distribution, and remote monitoring capabilities, reduce manual intervention and enable hassle-free operation. This increased automation not only enhances productivity but also significantly cuts down on operational costs.Energy Efficiency and Sustainability:The company's commitment toward a sustainable future is reflected in the design of the Graphite Heating Furnace. By leveraging the remarkable thermal conductivity of graphite, this heating system reduces energy consumption by ensuring rapid and efficient heat transfer. The furnace's superior insulation properties minimize heat loss and maximize energy utilization, leading to substantial energy savings. This eco-conscious approach aligns with global efforts to minimize carbon footprint and conserve energy resources.Safety and Reliability:The Graphite Heating Furnace incorporates numerous safety features, making it a reliable choice for industries demanding high-quality and secure heating processes. With advanced temperature and pressure controls, emergency shutdown mechanisms, and real-time monitoring systems, this furnace guarantees a safe operating environment for both personnel and equipment. Industries can rest assured that their processes will be conducted reliably and securely, ensuring consistent and defect-free production.Industry Applications and Future Potential:The versatility of the Graphite Heating Furnace makes it suitable for a wide range of applications. In the aerospace industry, it provides uniform heating for carbon fiber components, ensuring structural integrity and reducing defects. In automotive manufacturing, it enables precise thermal treatment of engine components, leading to improved performance and durability. Furthermore, its application in electronics and metallurgy sectors promotes efficient melting, refining, and heat treatment processes.Looking ahead, the company aims to further enhance the Graphite Heating Furnace's capabilities through continuous research and development efforts. Collaborations with industry leaders and ongoing innovation initiatives will drive the evolution of this heating system, ensuring it remains at the forefront of industrial heating technology.Conclusion:The Graphite Heating Furnace represents a significant milestone in industrial heating solutions. Its advanced graphite-based technology, unmatched efficiency, versatility, and commitment to sustainability make it a game-changer for industries worldwide. With its exceptional performance, automation capabilities, and emphasis on safety, this innovative heating system is set to revolutionize industrial heating processes, driving productivity, and cost-effectiveness in various sectors.

Next-Generation Semiconductor Material Breaking Barriers in Electronics Industry

The rise of electric vehicles has put the spotlight on new technologies that can provide the power and efficiency required for this growing market. One of the key technologies that enable electric vehicles to travel long distances is power electronics. This technology is what allows electricity to be stored and transported in a vehicle's battery pack and converted into high-voltage power that can drive the motor. Silicon Carbide (SiC) is emerging as a key player in this space, thanks to its capabilities to deliver high-efficiency, high-reliability power electronics.SiC has been around for a long time as a semiconductor material, but only recently has it gained traction in the power electronics industry. This is because it offers many advantages over traditional semiconductor materials like silicon, which is currently in widespread use. One of the key advantages of SiC is that it can handle higher voltages than silicon, which makes it ideal for use in high-power devices like electric vehicle inverters.Another advantage of SiC is its ability to operate at higher temperatures than silicon, which means it can handle more power without failing. This is particularly important in electric vehicles, where the power electronics need to operate at maximum efficiency for extended periods. SiC's high thermal conductivity also helps to keep the temperature down, reducing the need for bulky cooling systems.SiC offers increased efficiency, with the ability to reduce power losses and extend the driving range of electric vehicles. This makes SiC an important technology for providing the power and performance needed for the next generation of electric vehicles. The market is responding to this demand, with SiC-related businesses intensifying R&D efforts on this emerging technology.One company that has been at the forefront of SiC development is {company}. The company has invested heavily in SiC technology, and is now one of the leading players in the SiC market. The company's products cover a range of SiC applications, including power devices, modules, and systems. They specialize in designing and manufacturing SiC products that meet the highest quality standards, specifically for the automotive and industrial markets.{Company} has developed a range of SiC products that are tailored to meet the growing demand for high-performance electric vehicles. Their products offer high efficiency, superior reliability, and an extended lifespan compared to traditional silicon-based products. Their SiC MOSFETs, in particular, have been designed specifically for the electric vehicle market, offering high performance, compact size, and high reliability.In addition to their SiC MOSFETs, {company} has a range of SiC products that are suitable for a variety of applications, including renewable energy, industrial automation, and high-frequency communications. Their SiC modules are highly efficient and compact, making them ideal for use in electric vehicle chargers, battery management systems, and other high-power applications.{Company} is also involved in the development of next-generation SiC technology, including the development of 200mm SiC wafer production technology. This technology is expected to significantly increase the supply of SiC wafers, making them more accessible and cost-effective for a wider range of applications.In conclusion, the demand for high-performance electric vehicles is driving the development of new power electronics Technologies. SiC is emerging as a key player in this space, offering high efficiency, superior reliability, and an extended lifespan compared to traditional semiconductor materials. Companies like {company} have invested heavily in SiC technology and are developing innovative products that meet the demands of the rapidly growing electric vehicle market. As the market continues to expand, SiC is expected to play an increasingly important role in driving the next phase of electric vehicle growth.

An Introduction to Evaporation Crucibles: Why They Are Important in Many Industries

Evaporation Crucible Company Develops Innovative Technology for Material Processing NeedsEvaporation Crucible, a company that focuses on the design and manufacturing of crucibles, has been innovating its technology to better meet customers' material processing needs. For over a decade, the company has been providing high-quality crucibles to various industries that require exceptional performance and accuracy in their material processing. With its cutting-edge technology, Evaporation Crucible has taken the next step in advancing its service to its clients.Evaporation Crucible's state-of-the-art crucibles are known for their exceptional quality and performance, making them a top choice for various industries. From metal casting to semiconductor production, its customers rely on the company’s high-quality products for their material-processing needs. To better serve its clients, the company has expanded its product line to include a wider range of materials, designs, and sizes.One of the major innovations in Evaporation Crucible's technology is its advanced ceramic processing capabilities. The company has developed a proprietary method for producing complex ceramic shapes and components with high precision, ensuring consistency and quality in every product. Its advanced ceramic manufacturing process has significantly reduced lead times for its customers, allowing them to innovate and stay ahead of the competition.Not only does Evaporation Crucible offer high-quality products, but it also has an exceptional team that works closely with clients to ensure their specific needs are addressed. Comprising of experienced engineers, the company’s team provides technical support and helps clients choose the right materials based on their specific application requirements. Furthermore, the team works diligently to ensure timely and efficient deliveries, making sure that customers receive their products quickly and efficiently.The company also prioritizes safety and the environment. To that end, it has developed eco-friendly technology, minimizing waste and reducing its carbon footprint. Its recycling program also ensures that used crucibles are safely disposed of and that valuable materials are salvaged from the waste.The CEO of Evaporation Crucible, John Smith, expressed his excitement about the company's new technology and its potential impact on the industry. "Our advanced ceramic processing capabilities have opened up new possibilities for our customers, enabling them to create more complex and intricate shapes and components with high precision,” Smith said. “By focusing on high-quality materials, efficient processes, and excellent customer service, we have made it our mission to elevate the material processing industry, and we are excited about the endless possibilities and potential partnerships that this advancement creates."As the material processing industry continues to evolve and grow, Evaporation Crucible is poised to stay ahead of the curve with its commitment to innovation. Its focus on advanced ceramic processing technology, reliable customer service, safety, and environmental sustainability is a testament to the company’s vision and dedication to its clients. Evaporation Crucible's expansion of its product line is a reflection of its commitment to providing a diverse range of advanced materials that can meet the unique requirements of modern technology. With its exceptional team of experienced engineers, the company is well-positioned to provide innovative solutions to companies' specific material processing needs. They are truly the new leaders of innovation in the industry.

Discover the Advantages of Carbon Graphite Plates: A Comprehensive Guide

Title: Carbon Graphite Plates: A Revolutionary Advancement in Industrial ApplicationsIntroduction:[Company name] is proud to introduce its pioneering line of Carbon Graphite Plates, which are set to revolutionize various industrial applications. With their exceptional strength, durability, and conductivity, these plates offer unparalleled performance, making them an ideal choice for a wide range of industries. This breakthrough innovation is expected to have a significant impact on the manufacturing sector, electrical engineering, aerospace, automotive, and other relevant industries.Body:1. Background and Significance:Carbon graphite plates are composite materials made from carbon fibers and a matrix material (typically resin). They exhibit superior properties, including high strength-to-weight ratio, resistance to chemicals and extreme temperatures, electrical conductivity, and low thermal expansion. These outstanding characteristics make carbon graphite plates highly coveted materials for industrial applications.2. Industrial Applications:Carbon graphite plates find extensive usage in various sectors, including:Automotive Industry:With the constant need to reduce vehicle weight and enhance fuel efficiency, carbon graphite plates are increasingly used in manufacturing lightweight components like chassis, body panels, and battery enclosures. The impressive strength and heat resistance of these plates ensure improved safety, sustainability, and overall performance in the automotive sector.Aerospace Industry:The aerospace industry demands materials that can withstand extreme conditions while providing reliability and efficiency. Carbon graphite plates are ideally suited for applications such as aircraft wings, fuselage structures, and rocket nozzle components. Their lightweight nature significantly reduces aircraft weight, leading to increased fuel efficiency and enhanced maneuverability.Electrical Engineering:Carbon graphite plates are excellent electrical conductors, making them ideal for manufacturing components such as current collectors, brushes, and commutators in electric motors and generators. These plates offer low resistance, optimal thermal conductivity, and outstanding resistance to wear, making them the preferred choice in electrical engineering applications.Manufacturing and Machinery:In the manufacturing and machinery sector, carbon graphite plates are utilized in fabricating heat shields, furnace parts, and other components that require resistance to extreme temperatures and harsh chemical environments. The plates' superior thermal stability and resistance to corrosion increase equipment longevity and improve operational efficiency.Renewable Energy Sector:Carbon graphite plates are instrumental in the renewable energy sector, contributing to the efficient generation and storage of clean energy. They are employed in the production of wind turbine blades, solar panel frames, and battery technologies, aiding in the transition towards a sustainable future.3. Advantages of Carbon Graphite Plates:- Lightweight: Carbon graphite plates offer a remarkable strength-to-weight ratio, making them significantly lighter than traditional metal alternatives. This characteristic improves fuel efficiency, reduces transportation costs, and enhances overall productivity.- High Strength: These plates possess exceptional mechanical strength, allowing them to withstand heavy loads and resist deformation, ensuring prolonged product lifespan.- Thermal Stability: Carbon graphite plates exhibit exceptional resistance to extreme temperatures, making them viable candidates for applications subjected to thermal cycling or in contact with high-temperature fluids.- Electrical Conductivity: The superior electrical conductivity of carbon graphite plates enables efficient energy transfer, reducing power losses and enhancing overall system performance.- Chemical Resistance: Carbon graphite plates are highly resistant to corrosive chemicals and environmental factors that can degrade conventional materials. This property ensures their longevity and reduces maintenance costs.Conclusion:The introduction of Carbon Graphite Plates by [Company name] signifies a significant breakthrough in industrial materials. With their remarkable strength, lightweight nature, and exceptional electrical and thermal conductivity, these plates offer unmatched performance across diverse applications. The widespread implementation of carbon graphite plates presents an opportunity for industries to enhance productivity, efficiency, and sustainability. As [Company name] continues to innovate in this field, the potential applications for carbon graphite plates are boundless, driving a revolution in industrial manufacturing and technology.

Buy High-Quality Graphite Crucibles at Unbeatable Prices

Graphite Crucible Market Booming as VEVOR Leads the Way with Quality Products and Unbeatable PricesThe graphite crucible market has been experiencing steady growth in recent years as demand for these critical components in the manufacturing and metallurgical industries increases. Graphite crucibles are indispensable tools for melting and casting various metals and alloys, from precious metals like gold and silver to industrial metals like iron and copper.As a leading and emerging company in the manufacturer and exporting business, VEVOR has been at the forefront of supplying high-quality graphite crucibles to businesses and industries worldwide. With a commitment to supplying an incredible assortment of great quality products with unbeatable prices, VEVOR has earned an excellent reputation among customers.VEVOR's graphite crucibles stand out from the competition in both quality and affordability. Made from premium quality materials, these crucibles are designed to withstand high temperatures and harsh conditions, ensuring optimal performance and longevity. They are available in various sizes and shapes to cater to diverse needs, making them suitable for a wide range of applications.One of the key factors that set VEVOR's graphite crucibles apart from other brands is their competitive pricing. Despite the exceptional quality of these products, VEVOR offers them at unbeatable prices, making them accessible to businesses of all sizes and budgets. This has earned VEVOR a loyal customer base and helped the company to expand its reach worldwide.VEVOR's commitment to customer satisfaction is another factor that sets it apart from other competitors in the market. The company's customer support team is always on hand to provide guidance and support on product selection, usage, and maintenance. This ensures that customers get the right product for their needs and can use it effectively to achieve optimal results.In addition to graphite crucibles, VEVOR offers a vast range of other industrial products, kitchenware, machinery tools, sporting goods, pet products, home, and garden products. This diverse product range has helped VEVOR to become a one-stop-shop for businesses and individuals looking for quality products at affordable prices.VEVOR's quality products and excellent customer service have earned it various accolades and recognition in the industry. The company has won several awards for its outstanding performance in manufacturing and exporting, including the China Export Award and the Leading Foreign Trade Enterprise Award.Looking to the future, VEVOR is committed to maintaining its position as a market leader in the graphite crucible industry and expanding its reach to new markets and industries. The company plans to invest in research and development to improve its existing product line and introduce new innovative products that cater to the evolving needs of industries worldwide.In conclusion, the graphite crucible market is seeing steady growth, and VEVOR is at the forefront of supplying high-quality products at unbeatable prices. With its commitment to customer satisfaction, excellent customer support, and diverse range of products, VEVOR is a force to reckon with in the manufacturing and exporting industry. As the company looks to the future, it is poised to continue driving growth and innovation in the industry and solidifying its position as a market leader.

Vacuum Metallizing Machine for Roll-to-Roll Production of Alloy Films on PET, BOPP, CPP, PVC, and Paper

Roll to Roll Alloy Film Vacuum Metallizing Machine for Pet BOPP CPP PVC Paper - Graphite Crucible for Vacuum Metallizing FilmVacuum metallizing is the process of depositing a thin film of metal onto a substrate, such as plastic, paper, or glass, in a vacuum environment. This process is widely used in various industries, including packaging, automotive, cosmetics, and electronics. In this blog post, we will discuss the Roll to Roll Alloy Film Vacuum Metallizing Machine for Pet BOPP CPP PVC Paper and the importance of using Graphite Crucibles in the vacuum metallizing process.Roll to Roll Alloy Film Vacuum Metallizing MachineThe Roll to Roll Alloy Film Vacuum Metallizing Machine for Pet BOPP CPP PVC Paper is a type of web vacuum coater designed to deposit a thin film of metal alloy onto a continuous roll of material such as plastic, paper, or fabric. This type of vacuum metallizing machine is widely used in the packaging industry for producing decorative and functional films for a range of packaging applications. The machine is equipped with a vacuum chamber, a metal alloy deposition system, and a roll-to-roll web transport system. The substrate material is fed from a roll into the vacuum chamber, where it is pre-treated and then coated with a thin layer of metal alloy. The metal alloy is vaporized and deposited onto the substrate in a thin, uniform layer. The Roll to Roll Alloy Film Vacuum Metallizing Machine for Pet BOPP CPP PVC Paper has several advantages over other deposition techniques. It can produce films with high uniformity and consistency, is cost-effective, and supports high-volume production. Graphite Crucibles for Vacuum Metallizing FilmGraphite Crucibles are an essential component of the vacuum metallizing process. They are used to hold the metal alloy and heat it until it vaporizes and is deposited onto the substrate. The graphite crucible serves as a container for the metal alloy, which is heated to a temperature at which it vaporizes. The vaporized metal alloy is then deposited onto the substrate in the vacuum chamber.Graphite Crucibles are ideal for vacuum metallizing because they can withstand high temperatures, are chemically inert, and have excellent thermal conductivity. The crucibles are designed to withstand the harsh conditions of the vacuum chamber and ensure that the metal alloy is heated and vaporized evenly.ConclusionThe Roll to Roll Alloy Film Vacuum Metallizing Machine for Pet BOPP CPP PVC Paper is a critical component of the packaging industry. It enables the production of high-quality, functional, and decorative films at scale. However, to achieve the desired effect, it is essential to use high-quality Graphite Crucibles. Graphite Crucibles are essential to the vacuum metallizing process as they help to ensure that the conditions in the vacuum chamber are optimal for the vaporization of the metal alloy and the deposition of the thin film. With high-quality Graphite Crucibles, manufacturers can produce high-quality, durable, and decorative films that meet the needs of their customers.