- Home

- Graphite Molds For Abrasion Wheel

Top Graphite Molds Manufacturer for Abrasion Wheels - High-Quality Wholesale Supplier from China

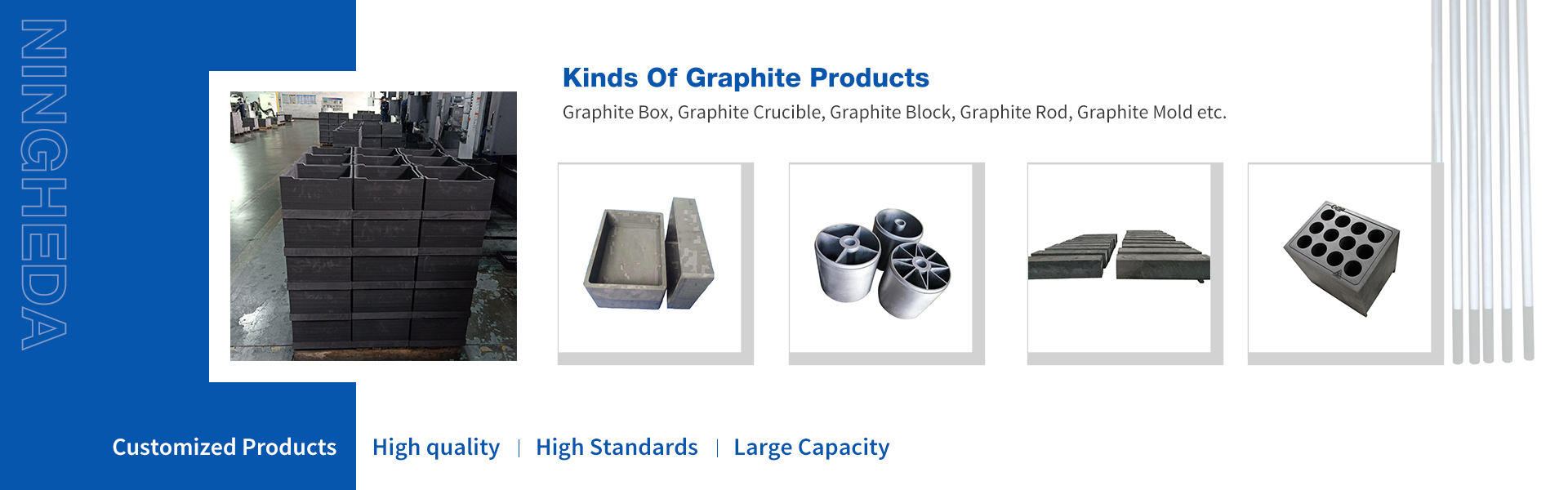

Jiangxi Ningheda New Material Co., Ltd. is a reputable manufacturer, supplier, and factory of graphite molds for abrasion wheel. Our graphite molds are high-quality and designed to meet the demanding needs of the abrasive wheel industry.

Our graphite molds for abrasion wheel are durable, resistant to wear and tear, and can tolerate high temperatures making them ideal for casting abrasive wheels. They are crafted with precision and accuracy to produce high-quality finished abrasive wheels that are reliable, safe, and effective.

Our company uses advanced technology and high-quality materials to produce our graphite molds for abrasion wheel. We work with our clients to ensure that their unique needs and expectations are met, and that we provide them with the best value for their investment.

Contact us today to learn more about our graphite molds for abrasion wheel, how they can benefit your business, and how our company can support your needs. We are committed to providing you with top-quality products and outstanding customer service.

Jiangxi Ningheda New Material Co., Ltd.

Company News

Related News

Graphite Box for anode powder

Looking for high-quality anode powder? Look no further than our Graphite Box! Our factory produces top-notch materials that guarantee optimal performance.

Graphite cluster wheel

Upgrade your ride with our durable Graphite Cluster Wheels. Made in our factory, these wheels are reliable and designed for maximum performance. Order now!

Graphite cave casting mould for gold sliver bar

Looking for a reliable factory to provide you with high-quality graphite cave casting moulds for gold and silver bars? Look no further! Our factory can provide you with top-of-the-line products to help improve your metal casting process.

Graphite ingot mould

Looking to buy high-quality Graphite Ingot Moulds for your industrial needs? Look no further than our factory! We offer superior quality moulds at competitive prices. Contact us today!

Graphite heater

Experience superior warmth with our Graphite heater, proudly manufactured in our factory. Enjoy efficient heating and savings on energy bills. Order now!

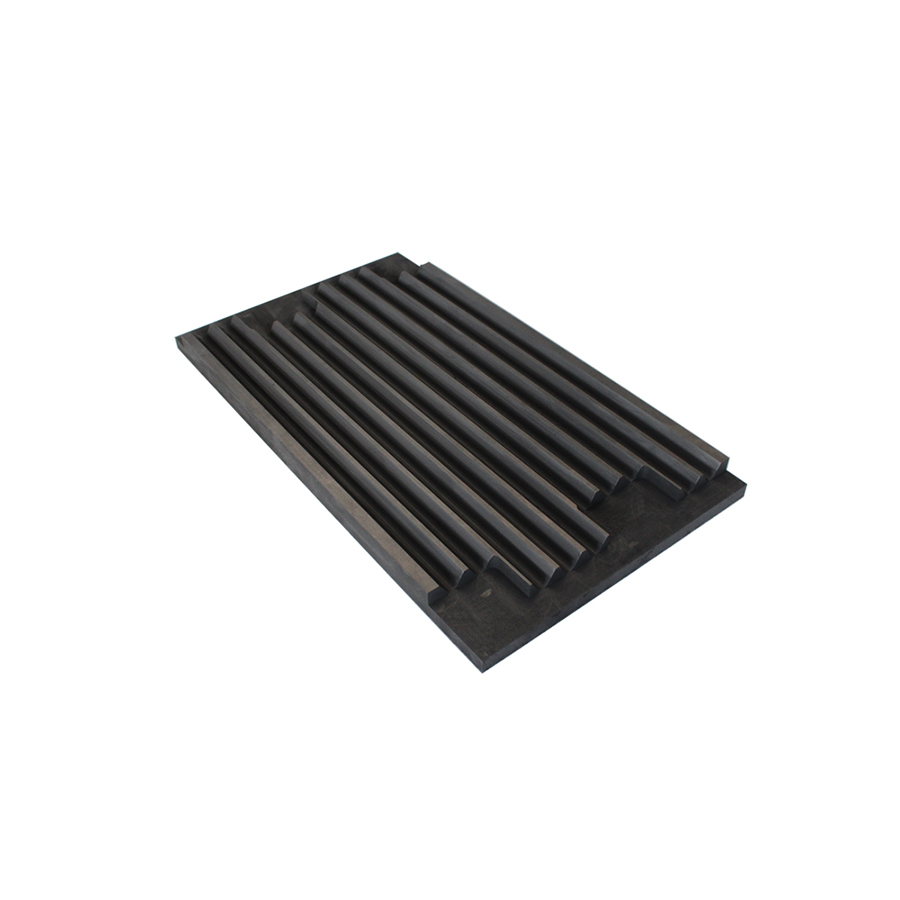

Graphite boat graphite plate for tunsgten carbide sintering

Graphite boat and graphite plate designed for tungsten carbide sintering process. We are a factory offering high-quality products for the best results.

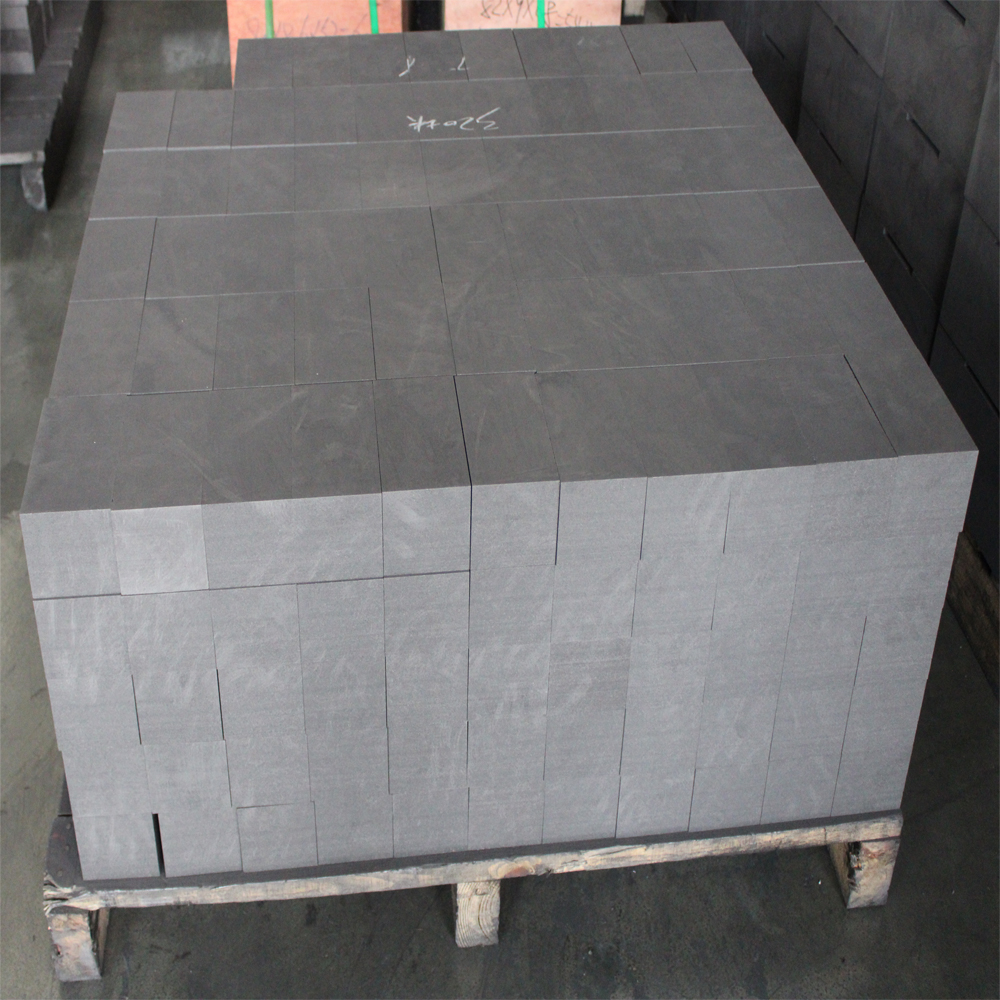

EDM graphite

As a factory, we produce high-quality EDM graphite for various applications. Our products are made with precision and are durable. Contact us for more information. #EDMGraphite #Factory #QualityGraphite

Graphite plate

Graphite Plate - High-quality and durable plates made by our factory. Pick the best graphite plate for your needs and experience exceptional performance.

Extruded graphite block for exothermic welding

Looking for high-quality Extruded Graphite Block for exothermic welding? Look no further than our factory! We offer top-notch products at competitive prices.

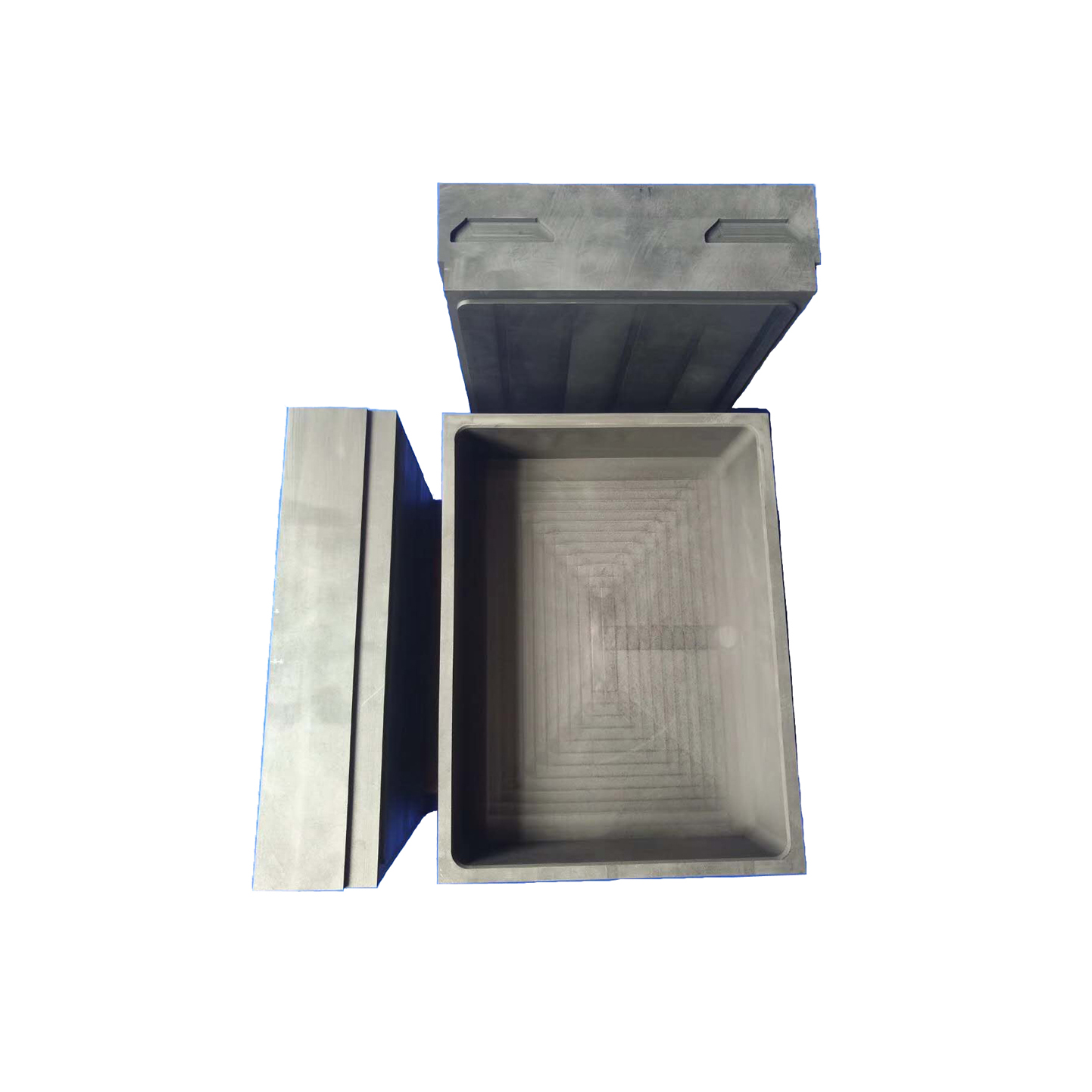

Square graphite boat

As a graphite boat factory, we offer top-quality square graphite boats for all your industrial needs. Our products are durable, efficient, and customized to meet your specifications.

Graphite Roller

Looking for high-quality Graphite Rollers? Our factory produces the best rollers for various applications. Contact us today for custom orders and competitive pricing.

Isostatic graphite

As a factory producing high-quality Isostatic Graphite, we strive for excellence in every step of the production process. Trust us for superior performance and reliability. Contact us today! #IsostaticGraphite #Factory #HighQuality

Extruded Graphite

Looking for high-quality Extruded Graphite products? Look no further than our factory! With top-notch materials and expert craftsmanship, we are your go-to source for all your graphite needs. Order now for exceptional service and unbeatable prices.

Graphite mold for continuous casting

As a factory that specializes in Graphite mold for continuous casting, we provide high-quality products that ensure efficient and precise casting processes. Our advanced technology and experienced craftsmen guarantee customer satisfaction.

Machined graphite block for processing exothermic welding graphite mold

Our factory produces high-quality machined graphite blocks for processing exothermic welding graphite molds. Trust us for reliable and durable solutions. Buy now!

- Top China Manufacturer of Graphite Molds for Abrasion Wheel - Wholesale Supplier and Exporter

- Reviews

- Related Videos

Introducing our high-quality graphite molds for abrasion wheel manufacturing. Our graphite molds are specially designed to produce high-quality abrasion wheels that meet the standards of the industry. Our molds are made with premium quality graphite that is durable and long-lasting, ensuring that our molds will produce high-quality wheels time and time again. Our molds are also customizable to fit the specific needs of our customers, allowing for variations in wheel size and shape. Our graphite molds are also incredibly versatile and can be used to create a variety of different abrasion wheels, including those used for cutting, grinding, and polishing. Additionally, our molds are designed to withstand high temperatures and high pressures, which makes them the perfect choice for manufacturing durable abrasion wheels that can withstand heavy use. At our company, we take pride in our dedication to quality and customer service. We work closely with our customers to understand their unique needs and preferences, ensuring that the molds we create are tailored to meet their specific requirements. In conclusion, our graphite molds for abrasion wheel manufacturing are the perfect choice for any company looking to produce high-quality wheels. Our molds are durable, customizable, and versatile, making them the ideal solution for any manufacturing needs. Contact us today to learn more about our products and services.

I recently purchased the Graphite Molds for Abrasion Wheel and have been thoroughly impressed with their performance. The molds are made from high-quality graphite material and have a smooth finish. They are perfect for casting abrasion wheels that are precise and uniform in shape. I found the molds to be durable and long-lasting, even after multiple uses. The final product was excellent with good sharpness, and there were no defects or cracks. I would highly recommend these molds to anyone looking to cast abrasion wheels for their business or personal use. Overall, an excellent purchase that exceeded my expectations!

Graphite molds for abrasion wheels are a necessity for those in the manufacturing industry. They provide a durable and precise shape for grinding wheels that withstand high temperatures and heavy use. The quality of the molds and the consistency in production is essential for producing uniform and high-quality abrasives. The graphite material also offers excellent resistance to chemical corrosion and thermal shock, making it an ideal choice for abrasive manufacturing. Overall, these molds are an indispensable tool for professionals in need of quality abrasion wheels.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours