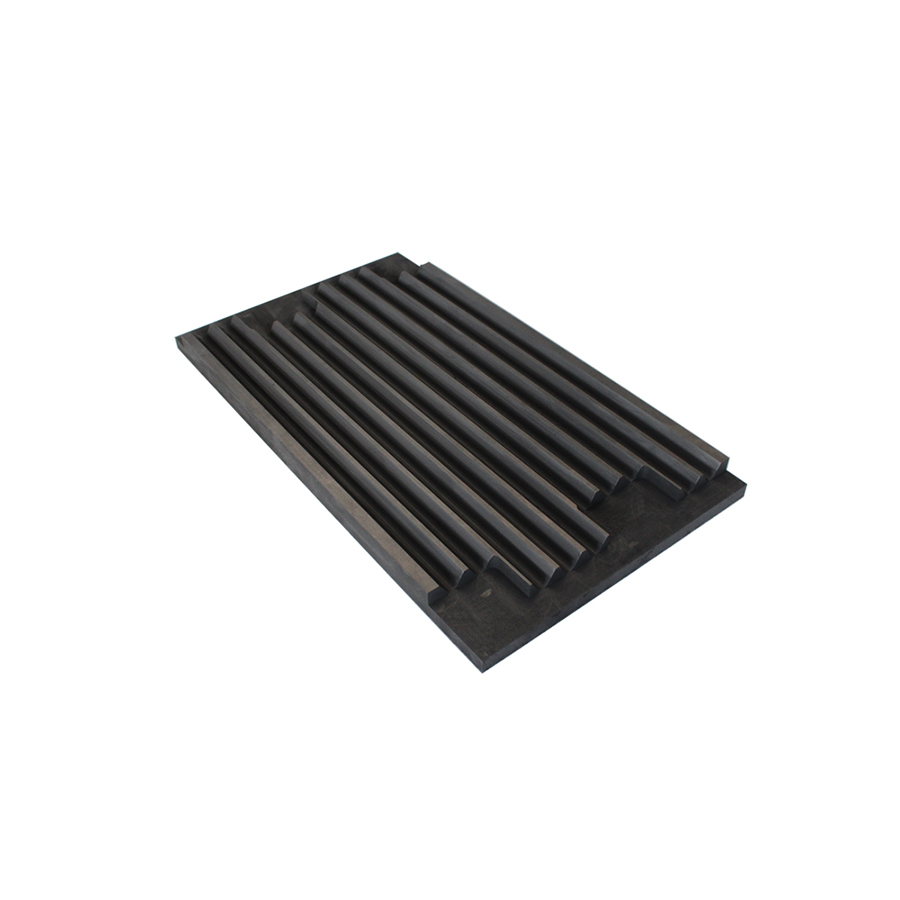

High-quality graphite rods for various applications available now

By:Admin

At the heart of ***'s innovation in graphite rods is their commitment to pushing the boundaries of what is possible in material science. By leveraging state-of-the-art manufacturing techniques and engineering expertise, *** has been able to produce graphite rods that are lighter, stronger, and more durable than traditional materials. This has opened up a world of new possibilities for engineers, designers, and manufacturers who are looking to create products that are not only more efficient and reliable but also more sustainable and environmentally friendly.

One of the key characteristics of graphite rods is their exceptional strength-to-weight ratio. This makes them an ideal choice for applications where weight savings are critical, such as in aerospace and automotive engineering. By using graphite rods, manufacturers can reduce the overall weight of their products while maintaining or even improving their strength and durability. This can lead to significant improvements in fuel efficiency, performance, and cost savings.

In addition to their strength and lightness, graphite rods also have excellent thermal and electrical conductivity properties. This makes them incredibly versatile and well-suited for a wide range of high-tech applications. For example, in the electronics industry, graphite rods are used in the production of heat sinks, which help to dissipate heat generated by electronic devices. This helps to improve the overall performance and reliability of these products while also extending their lifespan.

Furthermore, graphite rods are also highly resistant to corrosion, making them an ideal choice for use in harsh and demanding environments. This has led to their widespread use in industries such as oil and gas, where they are used in the construction of pipelines and other critical infrastructure. By using graphite rods, companies can ensure that their equipment and facilities are better able to withstand the challenges posed by corrosion and other environmental factors, leading to improved safety and reliability.

In the renewable energy sector, graphite rods are playing a crucial role in the development of advanced battery technologies. As the demand for clean and sustainable energy sources continues to grow, there is a pressing need for high-performance energy storage solutions. Graphite rods are being used to improve the performance and lifespan of batteries, making them more efficient and cost-effective. This has the potential to have a significant impact on the growth of renewable energy, as it will help to make these technologies more viable and accessible on a large scale.

***'s expertise in the development of graphite rods has positioned them as a key player in the industry. Their commitment to innovation and superior quality has earned them a reputation as a trusted partner for companies looking to integrate advanced materials into their products. Through their cutting-edge research and development efforts, they continue to push the boundaries of what is possible with graphite rods, opening up new opportunities and applications for this remarkable material.

With a focus on sustainability and environmental responsibility, *** is also committed to minimizing the environmental impact of their operations. Their manufacturing processes are designed to be as efficient and eco-friendly as possible, and they are constantly seeking new ways to reduce waste and energy consumption. This commitment to sustainability sets them apart as a leader in the industry and demonstrates their dedication to creating a better, greener future for all.

In conclusion, graphite rods are a game-changing material that is revolutionizing the way we think about engineering and design. With their exceptional strength, lightness, and versatility, they have the potential to drive innovation and progress across a wide range of industries. ***'s expertise and commitment to excellence have positioned them as a key player in this exciting field, and their continued dedication to research and development will undoubtedly lead to even more groundbreaking advancements in the future. As the demand for high-performance materials continues to grow, graphite rods will undoubtedly play a crucial role in shaping the technologies of tomorrow.

Company News & Blog

Silicon Carbide - The Innovative SemiconductorSilicon carbide, also known as SiC, is a highly advanced semiconductor material that has revolutionized the electronics industry. Its unique characteristics make it ideal for use in a wide range of applications, including high-temperature, high-voltage, and high-frequency electronic devices.SiC is a compound composed of silicon and carbon atoms, with a chemical formula of SiC. It is relatively rare in nature, occurring as the mineral moissanite, but it can also be synthesized artificially.The properties of SiC make it an attractive alternative to traditional semiconductors such as silicon. It has a wider bandgap, higher thermal conductivity, and higher electron mobility. As a result, SiC devices can operate at higher temperatures, handle higher voltages, and switch faster than their silicon counterparts.The use of SiC in semiconductor electronics has a long history, dating back to the early 1900s when it was first used in light-emitting diodes (LEDs) and detectors in radios. Today, SiC is used in a wide range of applications, including power electronics, wireless communication, and high-temperature sensors.One of the most significant advantages of SiC is its ability to handle high temperatures. SiC devices can operate at temperatures above 400°C, which is beyond the limit for silicon. This property makes it ideal for use in high-temperature environments such as aerospace, automotive, and power generation applications.Another advantage of SiC is its high electrical conductivity. SiC has a lower resistance than silicon, making it ideal for use in high-voltage devices. This property makes it ideal for use in power electronics applications such as motor drives, inverters, and power supplies.The use of SiC is not limited to electronics applications. Due to its exceptional hardness and durability, SiC is also widely used as an abrasive material. It is used in manufacturing processes such as grinding, honing, and polishing. Additionally, SiC can be sintered to form hard ceramics that are used in applications such as bulletproof vests, car brakes, and car clutches.Silicon carbide has also found its way into the jewelry industry. Synthetic moissanite, a gemstone made from SiC, is often used as a cheaper alternative to diamonds. Its high refractive index and unique optical properties make it a popular choice for engagement rings and other jewelry.In conclusion, SiC is a remarkable material that has changed the electronics industry. Its unique properties make it ideal for use in high-temperature, high-voltage, and high-frequency applications, where traditional semiconductors such as silicon cannot compete. SiC has a bright future ahead and will continue to drive innovation in the electronics and manufacturing industries.

Durable Graphite Trays: A Practical Solution for Serving and Display

Graphite trays are a crucial element in many industrial and manufacturing processes, and they play a vital role in the production, handling, and transportation of various materials. (Company Name) is a leading provider of high-quality graphite trays for a wide range of industries, offering exceptional performance and value to its customers.With over (number of years) years of experience in the industry, (Company Name) has established itself as a reliable and trusted supplier of graphite trays and other graphite products. The company prides itself on its commitment to quality, innovation, and customer satisfaction, and it continuously strives to exceed the expectations of its clients.Graphite trays are widely used in the metallurgy, chemical, and electronics industries, among others, and they are essential for processes such as powder metallurgy, sintering, and heat treatment. (Company Name) offers a comprehensive range of graphite trays in various sizes, shapes, and specifications to meet the diverse needs of its customers. The company's team of experts works closely with clients to understand their specific requirements and provide tailor-made solutions that meet their exact needs.One of the key advantages of graphite trays is their exceptional thermal stability and resistance to high temperatures, making them ideal for use in demanding industrial environments. (Company Name) utilizes the highest quality raw materials and advanced manufacturing techniques to ensure that its graphite trays deliver optimal performance and durability. This commitment to excellence has earned the company a solid reputation for reliability and consistency in the industry.In addition to its high-quality products, (Company Name) is also known for its exceptional customer service and support. The company's team of experienced professionals is dedicated to providing personalized attention and expert advice to help clients choose the right graphite trays for their specific applications. (Company Name) also offers comprehensive after-sales support, including maintenance and repair services, to ensure that its customers get the most out of their investment.As a customer-focused company, (Company Name) is continuously investing in research and development to further improve its products and stay at the forefront of the industry. The company is committed to staying ahead of the curve and meeting the evolving needs of its clients by embracing the latest technologies and innovative solutions. With a strong emphasis on quality and performance, (Company Name) is well-positioned to remain a leader in the graphite tray industry for years to come.In conclusion, graphite trays are essential components in many industrial processes, and (Company Name) is a leading provider of high-quality graphite trays for a wide range of applications. With a focus on quality, innovation, and customer satisfaction, the company is dedicated to delivering exceptional value to its clients and helping them achieve their goals. With its extensive experience, expertise, and commitment to excellence, (Company Name) is a trusted partner for businesses seeking reliable and high-performance graphite trays.

The Latest Graphite Price Per Kg: Find Out the Current Market Rates

The price of graphite has been a topic of interest for many industries and investors, as this mineral is widely used in various applications, such as in the manufacturing of lithium-ion batteries, steel production, and as a lubricant. The demand for graphite is expected to rise even further with the increasing focus on renewable energy and electric vehicles, which rely heavily on lithium-ion batteries. The current average price of graphite stands at approximately $8 per kg, a significant increase from the previous year's price.The global graphite market is dominated by several key players, including [Company Name]. [Company Name] has been a major contributor to the graphite industry, with a strong focus on product quality and innovation. The company has consistently delivered high-quality graphite products to its customers, and its dedication to research and development has led to the introduction of advanced graphite technologies.[Company Name] has strategically positioned itself in the graphite market by establishing itself as a reliable supplier with a wide range of graphite products, catering to diverse industries. With a strong emphasis on sustainability and environmental responsibility, [Company Name] has also implemented eco-friendly practices in its manufacturing processes, ensuring that its operations have minimal impact on the environment.The recent increase in the price of graphite has been attributed to several factors, including the growing demand for lithium-ion batteries and the disruptions caused by the COVID-19 pandemic. As the global economy gradually recovers from the effects of the pandemic, the demand for graphite is expected to soar, further driving up its price. Additionally, the shift towards electric vehicles and renewable energy sources has created a surge in demand for graphite, as it is an essential component in the production of lithium-ion batteries.The growing interest in sustainable energy solutions has also led to an increased focus on graphite mining and processing. As the demand for graphite continues to rise, many companies, including [Company Name], are ramping up their production capacities to meet the growing needs of various industries. This surge in production has also impacted the price of graphite, as manufacturers strive to keep up with the increasing demand.In response to the rising graphite prices, [Company Name] has reiterated its commitment to providing high-quality graphite products at competitive prices. The company's extensive experience in the graphite industry, coupled with its focus on technological advancements and innovation, positions it as a leading supplier in the market. With a strong dedication to customer satisfaction and product excellence, [Company Name] aims to continue to meet the evolving needs of its clients while navigating the changing landscape of the graphite market.As the global demand for graphite continues to grow, industry experts predict that the price of graphite is likely to remain on an upward trajectory. This presents both challenges and opportunities for companies like [Company Name], as they navigate the dynamics of the graphite market. The company's dedication to sustainable practices, technological innovation, and customer-centric approach will play a crucial role in maintaining its position as a key player in the global graphite industry.

High-Quality Graphite Crucible for Melting Copper

Graphite Crucible For Melting Copper: A Crucial Tool for MetalworkingIn the world of metalworking, the proper tools and equipment are crucial for achieving high-quality results. One such tool that is essential for melting copper and other metals is the graphite crucible. A graphite crucible is a container used for holding and melting metals at high temperatures. It is made of natural graphite and is designed to withstand the extreme heat required for melting copper, gold, silver, and other metals.(Graphite Crucible For Melting Copper) is a leading manufacturer of graphite crucibles for metalworking and foundry applications. The company has been in the industry for over 20 years and has built a strong reputation for producing high-quality and durable graphite crucibles.(Graphite Crucible For Melting Copper) offers a wide range of graphite crucibles in various sizes and shapes to meet the diverse needs of metalworkers and foundries. The company's crucibles are designed to withstand temperatures of up to 3000°C, making them ideal for melting copper and other high-temperature metals.The graphite crucibles manufactured by (Graphite Crucible For Melting Copper) are known for their excellent thermal conductivity, chemical resistance, and thermal shock resistance. These properties make them suitable for use in a variety of metalworking processes, including melting, casting, and refining.In addition to its standard graphite crucibles, (Graphite Crucible For Melting Copper) also offers custom crucible solutions to meet the specific requirements of its customers. The company's team of experienced engineers and technicians work closely with clients to develop customized crucible designs that are tailored to their unique applications.(Graphite Crucible For Melting Copper) is committed to providing its customers with the highest quality products and exceptional customer service. The company's manufacturing processes are ISO 9001 certified, ensuring that its crucibles meet the highest standards of quality and performance.In addition to its focus on quality, (Graphite Crucible For Melting Copper) also places a strong emphasis on innovation and continuous improvement. The company invests in research and development to constantly improve its crucible designs and develop new products that meet the evolving needs of the metalworking industry.The use of graphite crucibles in metalworking and foundry applications offers several advantages. Graphite crucibles have excellent thermal stability, allowing them to maintain their structural integrity at high temperatures. They also have low thermal expansion, which helps prevent cracking and damage during rapid temperature changes.Furthermore, graphite crucibles are non-wetting, meaning that they do not interact with the metals being melted or cast, which helps prevent contamination and ensures the purity of the final product. This makes graphite crucibles the ideal choice for melting and casting precious metals such as gold and silver.(Graphite Crucible For Melting Copper) is dedicated to providing its customers with the best graphite crucible solutions for their metalworking and foundry needs. The company's products are trusted by metalworkers and foundries around the world for their quality, reliability, and performance.As the demand for high-quality metal products continues to grow, the importance of reliable and durable graphite crucibles will only become more significant. With its commitment to excellence and innovation, (Graphite Crucible For Melting Copper) is well-positioned to meet the evolving needs of the metalworking industry and continue to be a trusted partner for metalworkers and foundries worldwide.

Top Suppliers of Gold Melting Crucibles

The Gold Melting Crucibles Suppliers market is experiencing a surge in demand as the global economy rebounds from the challenges of the past year. As businesses look to invest in reliable and high-quality equipment for their operations, the need for trusted suppliers has become paramount. One such supplier that is making waves in the industry is {Company Name}, a leading provider of gold melting crucibles. With a commitment to excellence and a focus on customer satisfaction, {Company Name} has become a go-to resource for businesses looking to invest in top-of-the-line equipment.{Company Name} has established itself as a prominent player in the gold melting crucibles market by continuously delivering high-quality products and exceptional customer service. The company's dedication to superior craftsmanship and attention to detail has earned it a strong reputation within the industry. Whether it's a small-scale jewelry business or a large industrial operation, {Company Name} has the expertise and resources to meet the needs of a diverse range of clients.In addition to the quality of its products, {Company Name} sets itself apart from other suppliers by offering a personalized approach to customer service. The company understands that every business is unique, and it takes the time to understand the specific needs and requirements of each client. This personalized approach allows {Company Name} to provide tailored solutions that address the unique challenges and goals of its customers.Furthermore, {Company Name} prides itself on its commitment to innovation and continuous improvement. The company invests in research and development to stay ahead of industry trends and technological advancements. This proactive approach ensures that {Company Name} is always equipped to provide its customers with the latest and most advanced solutions available in the market.As a result of its ongoing commitment to excellence, {Company Name} has experienced significant growth and success in recent years. The company's customer base has expanded, and its products have gained widespread recognition for their quality and reliability. {Company Name} has also forged strong partnerships with leading businesses in the industry, further solidifying its position as a trusted supplier of gold melting crucibles.Looking ahead, {Company Name} is poised for continued growth and success in the gold melting crucibles market. The company remains committed to upholding its high standards of quality and customer service while also exploring new opportunities for expansion and innovation. By staying true to its core values and leveraging its expertise, {Company Name} is well-positioned to meet the evolving needs of its customers and maintain its leadership in the industry.In conclusion, {Company Name} has emerged as a leading supplier of gold melting crucibles, thanks to its unwavering commitment to quality, innovation, and customer service. With a focus on personalized solutions and an eye towards the future, {Company Name} is primed for continued success in the market. Businesses looking for reliable and high-quality gold melting crucibles need look no further than {Company Name} for all their needs.

Innovative Porous Coating Graphite Mould: A New Advancement in Mould Technology

Porous Coating Graphite Mould has become an essential tool in the manufacturing industry, revolutionizing the way manufacturers create complex and intricate metal parts. The innovative technology behind Porous Coating Graphite Mould is making waves in the industry, providing manufacturers with a cost-effective and efficient solution for producing high-quality metal parts.With a history of over 20 years in the industry, {Company Name} has established itself as a leader in the production and distribution of Porous Coating Graphite Mould. The company has a strong focus on research and development, constantly striving to improve its products and stay ahead of the curve in terms of technological advancements. This commitment to innovation has allowed {Company Name} to become a trusted partner for manufacturers looking to improve their production processes.Porous Coating Graphite Mould is a versatile tool that can be used in a wide range of manufacturing applications. Whether it's producing automotive parts, aerospace components, or medical devices, Porous Coating Graphite Mould offers manufacturers the flexibility and precision they need to meet their production demands. The technology works by allowing gas to pass through the mould, which results in a uniform and consistent coating on the metal part being produced. This ensures that the final product has a smooth and flawless surface finish, free from imperfections or defects.One of the key advantages of using Porous Coating Graphite Mould is its ability to produce complex and intricate metal parts with high precision. This is particularly important in industries such as aerospace and medical manufacturing, where the smallest flaw in a part can have serious consequences. By using Porous Coating Graphite Mould, manufacturers can ensure that their parts meet the highest quality standards, while also reducing production time and costs.In addition to its precision and versatility, Porous Coating Graphite Mould also offers cost savings for manufacturers. The technology allows for a more efficient use of materials, reducing waste and minimizing the need for additional finishing processes. This results in lower production costs and a more sustainable manufacturing process overall.{Company Name} is committed to providing its customers with the highest quality Porous Coating Graphite Mould, backed by exceptional customer service and support. The company works closely with its clients to understand their specific production needs and develop customized solutions to meet those requirements. With a team of experienced engineers and technical experts, {Company Name} is able to provide comprehensive support to its customers, from initial consultation to ongoing maintenance and support.As the manufacturing industry continues to evolve and demand for high-quality metal parts grows, Porous Coating Graphite Mould is set to play a crucial role in shaping the future of manufacturing. With its precision, versatility, and cost-saving benefits, this innovative technology is helping manufacturers stay ahead of the curve and meet the ever-increasing demands of their customers. And with {Company Name} at the forefront of this technological revolution, manufacturers can trust that they have a reliable partner to support their production needs.

Exploring the Significance and Uses of Special Graphite

Special Graphite: The Key to High-Performance Industrial SolutionsIn the world of industrial manufacturing, finding the right materials is crucial for achieving high-performance results. One such material that has become indispensable in various industries is special graphite. Known for its exceptional properties and versatile applications, special graphite has become a go-to material for companies in need of high-quality and reliable solutions.Special graphite is a form of graphite that is engineered to possess specific properties that make it suitable for a wide range of industrial applications. It is characterized by its high purity, thermal stability, and excellent electrical conductivity, making it an ideal material for use in high-temperature and high-pressure environments. This unique combination of properties makes special graphite an essential component in the production of various industrial products, including heat exchangers, crucibles, and electrodes, among others.One company that has been at the forefront of special graphite production and innovation is {Company Name}. With over 30 years of experience in the industry, {Company Name} has established itself as a leading manufacturer and supplier of special graphite products to customers worldwide. The company's commitment to quality, innovation, and customer satisfaction has earned it a reputation for excellence in the industry.{Company Name} offers a wide range of special graphite products to meet the diverse needs of its customers. From high-purity graphite rods and blocks to customized graphite components, the company's product portfolio is designed to provide solutions for a wide range of industrial applications. Whether it's for the aerospace, automotive, semiconductor, or chemical industries, {Company Name} has the expertise and capabilities to deliver high-performance special graphite products tailored to its customers' specific requirements.One of the key strengths of {Company Name} lies in its extensive research and development efforts aimed at continuously improving the quality and performance of its special graphite products. The company's team of experts is constantly exploring new materials, manufacturing processes, and applications to push the boundaries of what special graphite can achieve. This dedication to innovation has enabled {Company Name} to stay ahead of the competition and remain a leader in the field of special graphite manufacturing.In addition to its strong focus on innovation, {Company Name} is committed to sustainability and environmental responsibility in its operations. The company adheres to strict environmental standards and practices to minimize its impact on the environment, from sourcing raw materials to delivering finished products. This commitment to sustainability not only reflects {Company Name}'s values but also resonates with customers who prioritize environmentally friendly solutions.As the demand for high-performance industrial solutions continues to grow, the importance of special graphite as a key material in various manufacturing processes cannot be overstated. Its unique combination of properties, coupled with {Company Name}'s expertise and commitment to excellence, makes special graphite an indispensable component for companies looking to achieve superior results in their operations.Looking ahead, {Company Name} remains focused on expanding its product offerings, enhancing its manufacturing capabilities, and strengthening its partnerships with customers to drive further innovation and growth. With a solid foundation built on quality, innovation, and customer satisfaction, {Company Name} is well-positioned to continue leading the way in the special graphite industry and provide high-performance solutions to its customers for years to come.

Discover the Benefits of Using a Graphite Heater in a Vacuum Furnace

Vacuum Furnace Graphite HeaterVacuum furnace graphite heater, a cutting-edge innovation in the field of heat treatment, has been gaining attention due to its superior performance and efficiency. This technology, offered by a leading global provider of thermal processing solutions, has set a new benchmark in the industry and is revolutionizing the way materials are treated for various applications.The vacuum furnace graphite heater is designed to operate in a high-temperature, low-pressure environment, making it ideal for heat treating processes that require precise control and uniform heating. Its advanced design allows for rapid heating and cooling, resulting in reduced cycle times and improved productivity. This makes it an ideal choice for industries such as aerospace, automotive, and tooling, where high-performance materials are crucial for meeting stringent quality standards.This innovative heating solution is a result of extensive research and development carried out by the company, a renowned manufacturer of industrial furnaces and heat-treating equipment. With a rich history spanning several decades, the company has established itself as a leading provider of thermal processing solutions for a wide range of industries, including aerospace, automotive, energy, and manufacturing.The company’s commitment to innovation and continuous improvement is evident in the vacuum furnace graphite heater, which incorporates state-of-the-art technology to deliver unmatched performance and reliability. The heater is constructed using high-quality graphite materials that are capable of withstanding extreme temperatures, ensuring long-term durability and consistent performance.In addition to its exceptional technical capabilities, the vacuum furnace graphite heater is also designed with user-friendly features, making it easy to operate and maintain. This includes advanced control systems that allow for precise temperature regulation, as well as safety features that ensure the protection of both the equipment and the operators.The company’s expertise in thermal processing extends beyond just the equipment itself, as it also offers comprehensive support services to ensure the optimal performance of its products. This includes installation, training, maintenance, and technical support, providing customers with a complete solution for their heat-treating needs.The introduction of the vacuum furnace graphite heater has generated significant interest in the industry, with many companies recognizing its potential to improve their heat-treating processes. Its ability to deliver consistent results, along with its energy efficiency and environmental friendliness, make it a highly attractive option for businesses looking to enhance their manufacturing capabilities.As the demand for high-performance materials continues to grow across various industries, the vacuum furnace graphite heater is poised to play a key role in meeting these requirements. Its ability to deliver precise and uniform heating, combined with its advanced features and support services, positions it as a leading solution for heat treatment applications.In conclusion, the vacuum furnace graphite heater represents a major advancement in the field of heat treatment, offering unparalleled performance and reliability. With its cutting-edge technology and comprehensive support services, it is set to transform the way materials are treated for a wide range of industrial applications. As the company continues to innovate and expand its offerings, it is well positioned to maintain its leadership in the thermal processing industry and meet the evolving needs of its customers.

Durable Graphite Box for Alloy: The Ultimate Solution for Metal Casting

Graphite Box for Alloy: The Latest Innovation from {Company}{Company} is proud to announce the launch of a new product in its line of innovative materials for the alloy industry. The Graphite Box for Alloy is the latest addition to the company's portfolio of high-quality materials designed to enhance the performance and efficiency of alloy production.The Graphite Box for Alloy is a revolutionary product that is designed to improve the overall quality and performance of alloys. It is made from high-quality graphite material that is durable and resistant to high temperatures, making it an excellent choice for use in the alloy manufacturing process. The innovative design of the Graphite Box for Alloy allows for better heat retention and distribution, resulting in more consistent and efficient alloy production.{Company} has a long-standing reputation for delivering high-quality materials to the alloy industry, and the Graphite Box for Alloy is no exception. The company's dedication to innovation and excellence is evident in the development of this new product, which is set to revolutionize the way alloys are produced.The Graphite Box for Alloy is designed to provide superior performance and reliability, making it an essential tool for alloy manufacturers. Its unique properties make it an ideal choice for a wide range of applications, from steel and iron production to the manufacturing of specialty alloys for aerospace and automotive applications.In addition to its impressive performance capabilities, the Graphite Box for Alloy is also designed with the environment in mind. Its durable construction and long lifespan make it a more sustainable option compared to traditional materials used in the alloy industry, reducing the overall environmental impact of alloy production.{Company} is committed to providing its customers with the best possible materials for their manufacturing needs, and the Graphite Box for Alloy is the latest example of this dedication. The company's extensive experience and expertise in the industry make it a trusted partner for alloy manufacturers looking to improve their production processes and achieve better results.With the launch of the Graphite Box for Alloy, {Company} continues to uphold its reputation as a leader in the development of high-quality materials for the alloy industry. The company's commitment to innovation and excellence sets it apart in the industry, and its latest product is sure to make a significant impact on the way alloys are produced.The Graphite Box for Alloy is now available for purchase, and {Company} is confident that it will quickly become an indispensable tool for alloy manufacturers around the world. With its superior performance, environmental benefits, and long-term reliability, this innovative product is set to redefine the alloy industry and set new standards for quality and efficiency.{Company} invites alloy manufacturers to experience the benefits of the Graphite Box for Alloy and discover how it can enhance their production processes. With its proven performance and sustainable design, this innovative product is sure to become a game-changer for the alloy industry.About {Company}:{Company} is a leading provider of high-quality materials for the alloy industry. With a commitment to innovation and excellence, the company has earned a reputation for delivering superior products that meet the needs of alloy manufacturers around the world. From graphite materials to refractories and more, {Company} is dedicated to providing the best possible solutions for its customers' manufacturing needs.

Easy Guide for Sourcing Quality Heater Components at Affordable Prices

As the world continues to evolve with technology, so do the ways we manage our homes. One important aspect of any household is the heating system, which often relies on heater parts for optimal functioning. Heater parts play a crucial role in maintaining a comfortable temperature inside homes, even during the coldest days of winter. That's why we are excited to announce the launch of our new line of heater parts, designed to offer customers reliable performance while ensuring maximum efficiency.Our company has been in the HVAC industry for over a decade, serving customers with pride and dedication. During this time, we have come to appreciate the importance of quality heating systems, and how they can make a significant impact on the comfort of our clients' homes. As we continually expand and improve our products, our goal remains focused on delivering top-notch, affordable solutions to meet all heating needs.Our new range of heater parts was developed to emphasize durability, affordability, and compatibility. The line features various heater parts, including gas valves, pressure switches, blowers, igniters, flame sensors, and other crucial components. We have ensured every product adheres to our strict quality control processes, guaranteeing the highest performance standards for our customers.Our gas valves are designed to work with all types of heaters, no matter the size or type. We understand the importance of gas valves, which are not only crucial to the functioning of the heating system but also safety. Our gas valves feature advanced technology, including smart controls, to provide precise gas regulation, ensuring that every user remains safe while enjoying their heating systems.Our pressure switches are essential to safety because they monitor water and gas pressure levels, ensuring that your heating system only operates when conditions are safe. Our switches are reliable, durable, and compatible with many different heating systems brands. Our switches have passed rigorous testing and adhere to industry standards, ensuring everyone's safety and comfort.Our blowers are designed to improve the heating system's performance, which is an essential part of generating and circulating warm air throughout homes. Our blowers come in different sizes, capacities, and types, ensuring there is a suitable option for all heating system users. Our blowers are easy to install, use little electricity, and are designed to last for years.Our igniters and flame sensors are crucial components that ensure safe ignition and heating of the air in your homes. They use advanced technology that quickly lights the pilot light and ignites the burner while maintaining flame safety standards. Our flame sensors consistently monitor the furnace's flame, which helps safeguard against explosions, gas leaks, and fire incidents. They ensure that the furnace ignites and runs smoothly, providing maximum comfort and safety.Finally, our new line of heater parts is designed to work with major heating system manufacturers' brands. This compatibility means that our customers can confidently purchase our products without fear of incompatibility with their systems.In conclusion, our new line of heater parts marks a significant milestone in our company's continued commitment to advancing the heating and cooling industry. We continue to work tirelessly to provide top-quality products that meet the highest performance, efficiency, and safety standards. Our new range of heater parts provides our customers with affordable and high-quality solutions to help keep their homes cozy and inviting, regardless of the weather outside.