Top Suppliers of Gold Melting Crucibles

By:Admin

{Company Name} has established itself as a prominent player in the gold melting crucibles market by continuously delivering high-quality products and exceptional customer service. The company's dedication to superior craftsmanship and attention to detail has earned it a strong reputation within the industry. Whether it's a small-scale jewelry business or a large industrial operation, {Company Name} has the expertise and resources to meet the needs of a diverse range of clients.

In addition to the quality of its products, {Company Name} sets itself apart from other suppliers by offering a personalized approach to customer service. The company understands that every business is unique, and it takes the time to understand the specific needs and requirements of each client. This personalized approach allows {Company Name} to provide tailored solutions that address the unique challenges and goals of its customers.

Furthermore, {Company Name} prides itself on its commitment to innovation and continuous improvement. The company invests in research and development to stay ahead of industry trends and technological advancements. This proactive approach ensures that {Company Name} is always equipped to provide its customers with the latest and most advanced solutions available in the market.

As a result of its ongoing commitment to excellence, {Company Name} has experienced significant growth and success in recent years. The company's customer base has expanded, and its products have gained widespread recognition for their quality and reliability. {Company Name} has also forged strong partnerships with leading businesses in the industry, further solidifying its position as a trusted supplier of gold melting crucibles.

Looking ahead, {Company Name} is poised for continued growth and success in the gold melting crucibles market. The company remains committed to upholding its high standards of quality and customer service while also exploring new opportunities for expansion and innovation. By staying true to its core values and leveraging its expertise, {Company Name} is well-positioned to meet the evolving needs of its customers and maintain its leadership in the industry.

In conclusion, {Company Name} has emerged as a leading supplier of gold melting crucibles, thanks to its unwavering commitment to quality, innovation, and customer service. With a focus on personalized solutions and an eye towards the future, {Company Name} is primed for continued success in the market. Businesses looking for reliable and high-quality gold melting crucibles need look no further than {Company Name} for all their needs.

Company News & Blog

Top Quality Graphite Supplier in China

China Graphite, a leading manufacturer and supplier of high-quality graphite products, has recently made significant strides in expanding their market presence and enhancing their product offerings. With a strong focus on innovation and quality, the company has established itself as a prominent player in the graphite industry.Founded in 2008, China Graphite has continuously evolved and grown to become a trusted partner for businesses in various sectors including metallurgy, chemical industry, mechanical engineering, and energy storage. The company’s extensive product range includes graphite electrodes, graphite blocks, graphite powder, and other customized graphite products, catering to the diverse needs of their global clientele.In line with their commitment to technological advancement and product development, China Graphite has invested heavily in research and development, resulting in the production of high-purity, high-density graphite products that meet the stringent requirements of modern industry standards. This has not only solidified the company’s position in the market but has also earned them a solid reputation for reliability and excellence.With a state-of-the-art manufacturing facility that is equipped with the latest machinery and technology, China Graphite is capable of producing large quantities of graphite products without compromising on quality. The company’s stringent quality control measures ensure that each product meets the desired specifications and is free from any defects, giving customers the assurance of superior performance and durability.Moreover, China Graphite has a strong commitment to environmental sustainability and operates in compliance with all relevant environmental regulations. The company places a high priority on minimizing its environmental impact by implementing eco-friendly manufacturing practices and reducing waste generation. This conscientious approach has earned China Graphite recognition as a responsible and environmentally conscious business entity.In addition to their unwavering focus on product quality and environmental responsibility, China Graphite also places great emphasis on providing exceptional customer service. The company’s dedicated team of professionals is committed to understanding the unique requirements of each client and delivering tailored solutions that meet their specific needs. This customer-centric approach has resulted in long-standing relationships with many clients and has contributed to the company’s sustained growth and success.Looking ahead, China Graphite is poised for further expansion and growth as they continue to explore new markets and forge strategic partnerships with industry players worldwide. Through their unwavering commitment to excellence, innovation, and customer satisfaction, the company is well-positioned to capitalize on emerging opportunities and further solidify their position as a global leader in the graphite industry.In conclusion, China Graphite stands as a testament to the potential of Chinese companies to compete and excel on the global stage. With a strong focus on innovation, quality, and customer satisfaction, the company has earned its reputation as a trusted partner for businesses in need of high-quality graphite products. As they continue on their path of growth and expansion, China Graphite is set to make a lasting impact on the graphite industry and beyond.

Top Graphite Rod Manufacturers and Suppliers in China - Mutual Benefits Await Overseas Customers

Graphite is one of the most commonly used materials in industries such as aerospace, automotive, and manufacturing. One of its unique properties is that it is a good conductor of electricity, making it ideal for use in products that require the transfer of electrical current. Graphite rods are a type of graphite product that is used in various applications.A graphite rod is a cylindrical bar made from a specific grade of graphite that is processed and machined to meet specific requirements. The rods are available in different diameters, lengths, and shapes. They are usually manufactured using high-purity graphite, which helps to improve their mechanical properties. Graphite rods are suitable for use in high-temperature, high-pressure, and corrosive environments.Teflon graphite rods are a type of graphite rod that is coated with Teflon, a fluoropolymer that is widely used in industries such as cooking, textiles, and aerospace. The Teflon coating helps to improve the overall characteristics of the graphite rod. Teflon graphite rods can withstand high temperatures and pressures, making them ideal for use in applications such as sealing systems, bearings, and gaskets.The use of Teflon graphite rods can help to reduce friction in machines and equipment, thereby improving their efficiency and performance. The Teflon coating can also help to protect the graphite rod from corrosion and chemical attack, thereby increasing its lifespan.Graphite rods are essential components in many industries, and their importance cannot be overstated. They are used in various applications such as nuclear reactors, aerospace, and automotive industries. Graphite rods have excellent thermal and electrical conductivity, which makes them ideal for use in products that require the transfer of electrical or thermal energy.In conclusion, Teflon graphite rods are a type of graphite rod that has been coated with Teflon. They are widely used in industrial applications where high temperatures and pressures are involved. The Teflon coating helps to improve the overall performance and lifespan of the graphite rod. Graphite rods, in general, are essential components in many industries, and their applications are limitless. They are an excellent choice for industry professionals who seek products with high thermal and electrical conductivity.

High-quality Graphite Material: A Key Component in Various Industrial Applications

Graphite Material, a leading provider of high-quality graphite products, has recently announced the launch of their latest product line. This new line of graphite materials is set to revolutionize the industry with its advanced technology and superior quality.The company has been at the forefront of graphite innovation for over a decade, and their commitment to research and development has resulted in a range of cutting-edge products that cater to a wide variety of industries. From aerospace to automotive, their graphite materials have been utilized in a multitude of applications, delivering exceptional performance and reliability.One of the key features of their new product line is its exceptional strength and durability. This is achieved through the company's proprietary manufacturing process, which ensures that their graphite materials are of the highest quality. Furthermore, the products are designed to withstand extreme temperatures and harsh conditions, making them ideal for use in demanding industrial environments.In addition to their superior performance, the new product line also offers significant cost savings for their customers. The company has invested heavily in state-of-the-art technology and processes, allowing them to produce their graphite materials more efficiently. As a result, they are able to offer competitive pricing without compromising on quality, providing their clients with an excellent return on their investment.Furthermore, Graphite Material is committed to sustainability and environmental responsibility. They have implemented strict quality control measures to minimize waste and reduce their carbon footprint. Through the use of eco-friendly manufacturing practices, they are able to produce graphite materials that are not only high-performing but also environmentally friendly.The release of this new product line further solidifies Graphite Material's position as an industry leader. With a strong focus on innovation, quality, and customer satisfaction, the company continues to push the boundaries of what is possible with graphite materials. Their commitment to excellence has earned them a stellar reputation in the industry, and they are trusted by some of the biggest names in manufacturing and engineering.In addition to their exceptional products, Graphite Material also offers unparalleled customer service. Their team of experts is dedicated to providing comprehensive support to their clients, from product selection to after-sales assistance. This level of commitment has earned them a loyal customer base, as clients can rely on them for all their graphite material needs.Looking ahead, Graphite Material is poised for even greater success as they continue to innovate and expand their product offerings. With a focus on research and development, they are constantly exploring new technologies and materials to meet the evolving needs of the industry. Their dedication to excellence and their unwavering commitment to quality ensures that they will remain at the forefront of the graphite material industry for years to come.In conclusion, Graphite Material's new product line is set to make a significant impact on the industry. With its advanced technology, superior quality, and cost-effective pricing, it is sure to be a game-changer for their clients. As the company continues to grow and innovate, they are well-positioned to maintain their position as a leading provider of high-quality graphite materials.

Newly Released Graphite Box Enhances Storage and Transportation of Anode Powder

Graphite Box For Anode Powder Revolutionizes the Battery IndustrySeptember 15, 2022In a groundbreaking move that promises to revolutionize the battery industry, a leading global manufacturer has introduced an innovative product - the Graphite Box for Anode Powder. This cutting-edge solution offers a range of benefits that are set to transform the way batteries are produced, used, and recycled. With its exceptional performance, versatility, and sustainable features, this revolutionary product is set to disrupt the industry status quo.The Graphite Box for Anode Powder is a game-changer when it comes to battery manufacturing. Designed by an industry-leading company known for their commitment to innovation, quality, and sustainability, this ground-breaking product is set to enhance the performance and longevity of batteries across various industries.One of the key advantages of the Graphite Box lies in its exceptional ability to provide stability and consistency in anode powder production. The graphite material is known for its excellent thermal conductivity, which allows for efficient heat dissipation during the battery manufacturing process. This results in superior quality anode powder with optimized electrochemical properties.Furthermore, the Graphite Box boasts outstanding durability, ensuring it can withstand extreme temperature variations and chemical interactions, thereby extending its lifecycle and reducing the frequency of replacements. This not only results in significant cost savings for battery manufacturers but also reduces the environmental impact associated with frequent replacements.To ensure the highest standards of sustainability, the Graphite Box is crafted using eco-friendly materials. By reducing the reliance on non-renewable resources and maximizing energy efficiency, it promotes a greener approach to battery manufacturing. This aligns with the global push towards a more sustainable future and positions the Graphite Box as a frontrunner in supporting environmental conservation efforts.The versatility of the Graphite Box sets it apart from traditional alternatives. It can be used across a wide range of battery types, from lithium-ion batteries in electric vehicles and portable electronics to energy storage systems for renewable sources. This adaptability not only simplifies the manufacturing process but also streamlines the supply chain, making it more efficient and cost-effective.Moreover, the Graphite Box's innovative design allows for easy integration into existing production lines, ensuring a seamless transition for manufacturers. The compatibility and flexibility of this product enable battery manufacturers to optimize their operations without significant disruptions, fostering quicker adoption and industry-wide acceptance.The Graphite Box's impact extends beyond the manufacturing stage. As increasing emphasis is placed on battery recycling to minimize waste, this revolutionary product stands out due to its recyclability. The graphite material is easily separable from other battery components, simplifying the recycling process and minimizing resource wastage. This marks a significant advancement in the circular economy model and reduces the environmental footprint associated with battery disposal.The introduction of the Graphite Box for Anode Powder marks a major milestone in the battery industry, offering unmatched performance, sustainability, and versatility. As the world continues to prioritize renewable energy and electric mobility, this innovative solution presents manufacturers with a powerful tool to meet the surging demand for high-quality, sustainable batteries. With its potential to reduce costs, improve battery performance, and contribute to a cleaner planet, the Graphite Box is set to reshape the industry landscape and unlock a new era of battery technology.About the Company:The company behind the Graphite Box for Anode Powder is a global leader in advanced materials and technology solutions for various industries. With a strong focus on research and development, innovation, and sustainability, they are dedicated to delivering cutting-edge products that surpass customer expectations. With a robust global presence and an unwavering commitment to quality, this company continues to shape the future of industries around the world.

High-Quality Graphite Box for Ndfeb: What You Need to Know

Leading Graphite Box Company Introduces Innovative Solution for Ndfeb MaterialsGraphite Box Company is pleased to introduce an innovative solution for the transportation and storage of Ndfeb (neodymium-iron-boron) materials. Ndfeb is a type of rare earth magnet that is widely used in various industries, including electronics, automotive, and renewable energy. Due to their high magnetic properties, Ndfeb materials require special care and protection during transportation and storage to prevent damage and ensure their performance.Graphite Box Company has developed a new and advanced packaging solution specifically designed for Ndfeb materials. The company's graphite boxes are made from high-quality graphite material that provides excellent thermal and electrical conductivity, high mechanical strength, and chemical resistance. These properties make graphite boxes an ideal choice for the transportation and storage of Ndfeb materials, as they offer superior protection against external factors such as temperature fluctuations, moisture, and physical impact.The innovative design of Graphite Box Company's packaging solution also includes custom foam inserts that are precisely engineered to securely hold Ndfeb materials in place, preventing them from shifting or coming into contact with each other during transportation. This ensures that the magnetic properties of the materials remain uncompromised and that they arrive at their destination in optimal condition.In addition to providing superior protection, Graphite Box Company's packaging solution is also designed with sustainability in mind. The graphite material used in the boxes is highly durable and long-lasting, reducing the need for frequent replacement and minimizing environmental impact. Furthermore, the company is committed to using eco-friendly production processes and materials, making their packaging solution a truly sustainable choice for businesses that prioritize environmental responsibility."We are thrilled to introduce our new graphite boxes for the transportation and storage of Ndfeb materials," said [company spokesperson]. "We understand the unique challenges associated with handling Ndfeb materials, and our goal is to provide a reliable and sustainable packaging solution that meets the specific needs of our customers. Our graphite boxes offer unmatched protection and peace of mind, allowing businesses to transport and store Ndfeb materials with confidence."Graphite Box Company has a long-standing reputation for delivering high-quality, reliable packaging solutions for various industries. The company's commitment to innovation, sustainability, and customer satisfaction has established them as a leading provider of protective packaging solutions, and their new graphite boxes for Ndfeb materials further solidify their position in the market.In conclusion, Graphite Box Company's innovative packaging solution for Ndfeb materials is set to revolutionize the way businesses handle and transport these valuable and sensitive materials. With their superior protection, sustainable design, and commitment to customer satisfaction, Graphite Box Company continues to be a trusted partner for businesses seeking reliable and innovative packaging solutions. Businesses can now confidently transport and store Ndfeb materials knowing that they are protected by the highest quality graphite boxes on the market.

High-Temperature Graphite Rods: A Guide to Heating Technologies

Heating Graphite Rods: The New Innovation by {Company Name}In the ever-evolving world of technology and industrial equipment, innovation is key to staying ahead of the competition. {Company Name} is proud to announce the launch of their latest innovation in the field of heating graphite rods. With a strong commitment to research and development, the company has developed a cutting-edge product that is set to revolutionize the industry.Graphite rods are essential components in a wide range of industrial applications, including semiconductor manufacturing, metallurgy, and high-temperature furnace operations. Traditionally, these rods have been made from materials such as carbon and silicon, but {Company Name} has taken a bold step forward by introducing a new type of graphite rod that offers superior performance and durability.The heating graphite rods developed by {Company Name} are designed to withstand extreme temperatures and harsh operating conditions, making them ideal for use in a variety of industrial processes. The company has invested heavily in research and development to ensure that their new product meets the highest standards of quality and reliability.One of the key advantages of {Company Name}'s heating graphite rods is their exceptional heat conductivity. This allows for efficient and uniform heating, resulting in improved process efficiency and product quality. In addition, the rods are highly resistant to corrosion, making them suitable for use in aggressive chemical environments.Furthermore, the company has also focused on optimizing the mechanical properties of their graphite rods. By carefully selecting the raw materials and refining the manufacturing process, {Company Name} has created a product that is not only highly durable, but also capable of withstanding mechanical stress and vibration.{Company Name} has also taken steps to ensure that their new graphite rods are environmentally friendly. The production process is designed to minimize waste and energy consumption, and the rods themselves are recyclable, providing a sustainable solution for industrial heating applications.In addition to the technological advancements, {Company Name} is also dedicated to providing exceptional customer service. The company's team of engineers and technical experts are on hand to provide guidance and support to customers, helping them to select the right heating graphite rods for their specific needs.The launch of {Company Name}'s new heating graphite rods has already generated significant interest within the industry. Customers from a wide range of sectors, including manufacturing, engineering, and research, have expressed eagerness to explore the potential benefits of this innovative product."We are excited to introduce our new heating graphite rods to the market," said {Spokesperson}, a representative of {Company Name}. "We believe that this product represents a significant advancement in the field of industrial heating technology, and we are confident that it will deliver tangible benefits to our customers."The introduction of {Company Name}'s heating graphite rods is a testament to the company's commitment to innovation and excellence. By combining cutting-edge technology with a focus on quality and sustainability, {Company Name} has positioned itself as a leader in the field of industrial heating solutions. As the industry continues to evolve, {Company Name} is poised to remain at the forefront, driving progress and delivering value to its customers.

How Graphite-Based Materials Are Changing Industries

Graphene Made Of Breakthrough: Unlocking the Potential of Graphene Utilizing Advanced Manufacturing TechniquesWith a vision to revolutionize the materials industry, a leading company in the field of advanced materials has announced a groundbreaking innovation — a new type of graphene made using advanced manufacturing techniques. This breakthrough in materials science is set to unlock the true potential of graphene and bring us closer to a future filled with incredible possibilities.Graphene, a two-dimensional material composed of a single layer of carbon atoms, is renowned for its exceptional properties. It is the thinnest and strongest material known to mankind, with extraordinary electrical and thermal conductivity. However, despite its potential for various applications, widespread use of graphene has been hindered by challenges in its manufacturing processes and the high cost associated with its production.Recognizing these constraints, the research and development team at {Company Name} embarked on a journey to revolutionize the production of graphene. Through their tireless efforts, they have successfully developed an innovative technique that allows for the large-scale manufacturing of high-quality graphene at a significantly reduced cost compared to traditional methods.This revolutionary graphene production technique leverages the advantages of a proprietary manufacturing process, ensuring the utmost control over the quality and characteristics of the material. By carefully optimizing the growth conditions of graphene on a metal catalyst, the team at {Company Name} has achieved unparalleled uniformity and high crystallinity in the final product.The implications of this breakthrough extend to various industries, including electronics, energy, aerospace, and healthcare. In the electronics sector, graphene promises to revolutionize the field of transparent conductive films, enabling flexible and foldable touchscreens, ultrafast transistors, and high-capacity batteries. Its exceptional thermal conductivity also holds great potential for enhancing the efficiency of electronics by improving heat dissipation.Furthermore, the aerospace industry will benefit from graphene's remarkable strength-to-weight ratio, which could enable the development of lighter and more fuel-efficient aircraft. Graphene has the potential to be used in the construction of advanced composites, leading to stronger and more durable materials for aircraft structures.In the energy sector, graphene's high electrical conductivity could pave the way for the development of next-generation solar cells and batteries. Not only could graphene improve the efficiency of solar panels by enhancing charge transport within the device, but it could also revolutionize energy storage by enabling faster-charging batteries with higher energy densities.The medical field also stands to gain from this breakthrough. Graphene's exceptional biocompatibility and electrical properties open up new avenues for applications in biosensing, drug delivery, and tissue engineering. Its high surface area-to-volume ratio allows for maximum interaction with cells, making it an ideal candidate for targeted drug delivery systems. Additionally, graphene-based biosensors could revolutionize diagnostics through their ability to detect a wide range of diseases with high sensitivity.The development of scalable manufacturing techniques for high-quality graphene is a significant achievement that will shape the future of numerous industries. By overcoming traditional manufacturing constraints and reducing costs, {Company Name} has taken a massive step forward in unlocking the full potential of graphene.With this breakthrough, the company aims to collaborate with industry partners and researchers to accelerate the adoption of graphene-based solutions. By providing access to high-quality and cost-effective graphene, {Company Name} envisions a world where the extraordinary properties of this remarkable material can be harnessed to propel us into a future filled with innovation and possibilities.As the demand for sustainable and advanced materials continues to rise, the announcement of this graphene breakthrough brings hope for a brighter and more technologically advanced future. The era of graphene-based technologies is upon us, and {Company Name} is leading the charge towards unlocking the full potential of this remarkable material.

Durable Graphite Boat for Square Applications Rises in Popularity: Market Insights and Analysis

Title: High-Quality Graphite Boat Facilitates Diverse Industrial ApplicationsIntroduction:Graphite, a versatile and durable material known for its excellent thermal and electrical conductivity, has taken center stage in various industrial applications. Amongst the leaders in graphite manufacturing, a renowned company has recently unveiled their cutting-edge Square Graphite Boat - a breakthrough product that is revolutionizing multiple industries. With a commitment to innovation and an unwavering focus on quality, this new graphite boat is set to address the needs of diverse sectors and contribute to their growth. 1. The Versatility of Graphite:Graphite, an allotrope of carbon, is highly valued for its unique properties, making it indispensable in numerous industries. It is widely used in manufacturing electrical products, semiconductors, batteries, fuel cells, and even in the aerospace industry due to its lightweight nature. The thermal stability and corrosion resistance of graphite also make it an ideal material for use in high-temperature furnaces, crucibles, and electrodes. Recognizing the potential of graphite, this pioneering company has introduced the Square Graphite Boat to enhance industrial processes across sectors.2. The Key Features of Square Graphite Boat:The Square Graphite Boat boasts several noteworthy features, making it stand out in the market. First and foremost, its impeccable design ensures uniform heat distribution, reducing the possibility of thermal stress cracks during high-temperature applications. The boat's superior thermal conductivity guarantees efficient heat transfer, resulting in enhanced productivity and reduced energy consumption. Furthermore, the boat's high-density graphite composition coupled with its exceptional machinability allows for intricate and precise customization, catering to the unique requirements of different industrial applications.3. Revolutionary Applications of Square Graphite Boat:(a) Semiconductor Manufacturing Sector:In the semiconductor industry, where precision and reliability are paramount, the high-purity graphite material of the Square Graphite Boat proves to be indispensable. Used as a critical component in thermal processes, this boat ensures optimal heat distribution, preventing defects in the delicate semiconductor wafers. The boat's longevity and resistance to chemical reactions make it a sustainable and cost-effective solution.(b) Energy Storage and Microelectronics Industry:With the rapid advancement in the development of energy storage devices such as lithium-ion batteries and fuel cells, the demand for quality graphite boats has surged. The Square Graphite Boat, with its excellent electrical conductivity, corrosion resistance, and uniform heat distribution, ensures the efficient functioning and extended lifespan of these energy storage devices, consequently benefiting the electric vehicle and renewable energy sectors.(c) Metallurgical and Chemical Industries:Graphite boats find their application in high-temperature processes like smelting and refining metals due to their superb thermal resistance. The Square Graphite Boat, thanks to its seamless design and superior thermal conductivity, optimizes these processes by reducing energy loss and enhancing heat transfer efficiency. Its chemical stability further ensures a clean, contaminant-free environment, making it invaluable in controlled chemical reactions and laboratory settings.4. Commitment to Quality and Sustainability:The company behind the Square Graphite Boat is committed to producing high-quality, sustainable products. They adhere to stringent quality control measures, ensuring that every boat manufactured meets industry standards and customer specifications. Additionally, their responsible sourcing practices guarantee the usage of eco-friendly materials, minimizing the environmental impact.Conclusion:The Square Graphite Boat represents a significant technological milestone in the graphite industry, addressing the evolving needs of diverse sectors. Its impeccable design, high thermal conductivity, and resistance to thermal stress cracks make it an indispensable tool in various high-temperature industrial processes. The versatile applications of this boat, from semiconductor manufacturing to energy storage and metallurgical industries, highlight its immense potential. With a strong focus on quality and sustainable practices, the company behind this innovative product is steadfastly contributing to the growth and development of industries around the globe.

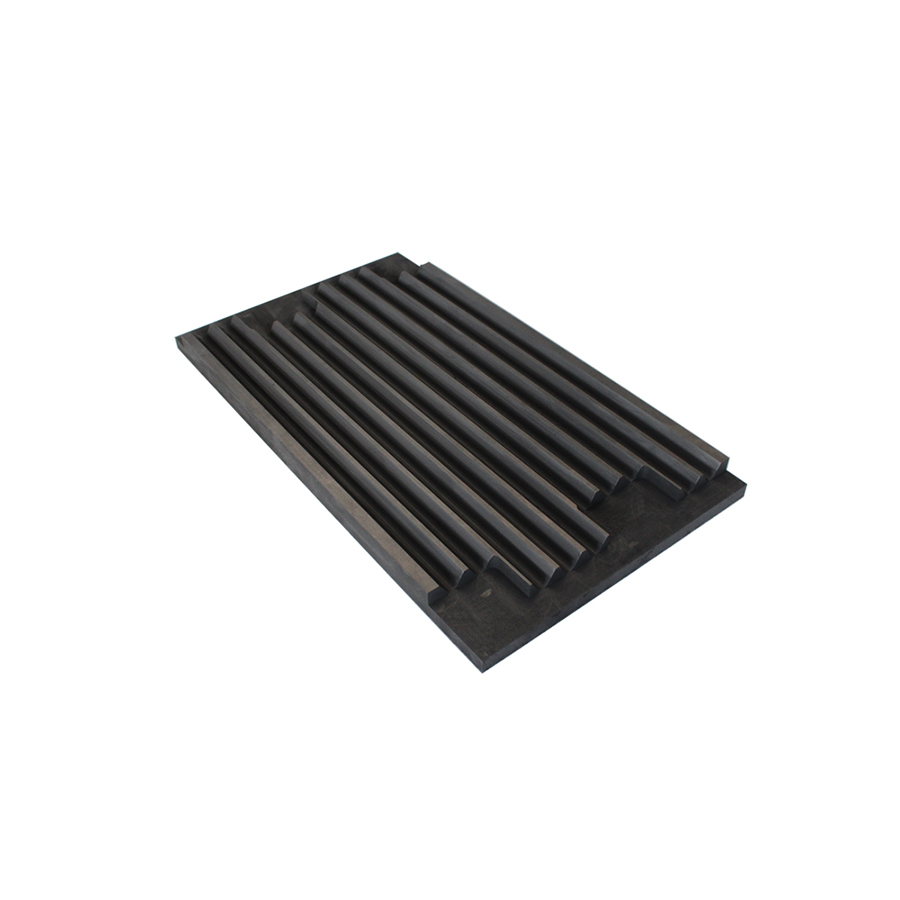

High Temperature Graphite Crucible Melting Pots for Induction Heating and Metal Melting - Various Sizes Available

Graphite Crucible Melting Pots: The Ultimate Choice for High-Temperature Metal MeltingIndustries that require melting metals for production purposes are in dire need of reliable and durable pots for the job. A suitable pot is an essential tool for any industry that wants to melt metals at high temperatures efficiently. Graphite Crucible Melting Pots are the go-to pots for any industry that requires high output and quality melting results. Graphite Crucible Melting Pots have a wide range of applications, including foundries, jewelry making, and several other commercial applications. They are small graphite crucibles used for induction heating and melting metals up to 1650°C. They have a broad range of sizes available, making them ideal for various melting needs.Industries are always looking for reliable, durable, and practical melting pots that can handle their day-to-day operations. Graphite Crucible Melting Pots are the perfect fit for the job, and they offer several advantages, including:1. Highly Conductive: Graphite is an excellent conductor of heat, and when used in making crucibles, it provides quick and efficient melting of metals. The graphite crucible melting pots offer a superior heat transfer rate, ensuring that the melting process is short and efficient. 2. Durable: Graphite has a high melting point, making it an ideal material for use in making crucibles. The graphite crucible melting pots can handle high temperatures, and they are designed to withstand constant thermal shock and the corrosive nature of most molten metals. 3. Versatile: Graphite crucible melting pots come in various sizes, making them ideal for different applications. They are used in jewelry making, metalworking, and casting and molding industries. 4. Cost-Effective: Graphite crucible melting pots require minimum maintenance, and they offer an extended lifespan. They provide a cost-effective solution to industries looking for reliable melting pots that can handle their day-to-day operations.The company behind the creation of graphite crucible melting pots is renowned for providing quality and reliable products to its clients. They specialize in manufacturing graphite products for various industrial applications. Their graphite crucible melting pots are the perfect fit for companies looking for efficient and reliable melting solutions. They offer a broad range of sizes, and they are designed to withstand the harsh conditions of the melting process. The company takes pride in its products and always focuses on delivering quality and reliable solutions to its clients. Their team of experts uses the latest technology and techniques to manufacture graphite crucible melting pots that meet the specific needs of clients.In conclusion, graphite crucible melting pots are the ultimate choice for industries that require high-temperature metal melting solutions. They are durable, versatile, and cost-effective, making them the preferred choice for many companies. With a company that prides itself on delivering quality and reliable solutions, clients can rest assured that they are getting the best melting solution for their needs.