Main performance of graphite heater

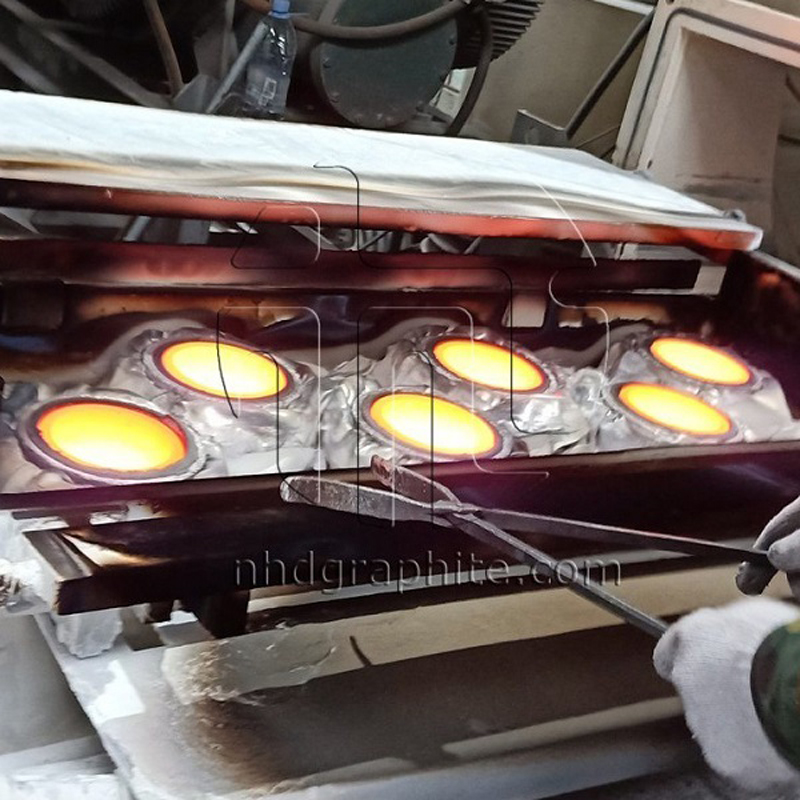

The oxidation speed and volatilization speed of graphite affect the service life of the heating element. When the vacuum degree is 10-3~10-4 mmHg, the operating temperature should be below 2300℃. In the protective atmosphere (H2, N2, Ar, etc.), the operating temperature can reach 3000℃. Graphite cannot be used in the air, otherwise it will be oxidized and consumed.

The thermal expansion coefficient of graphite is small, and the size is stable when the temperature rises, which is one of the important characteristics in the structural design of the heating element.

The mechanical strength of graphite is below 2500°C and increases with the increase of temperature. When the temperature exceeds 2500°C, the strength drops quickly.

The thermal conductivity of graphite decreases with increasing temperature. When the furnace is running at a high temperature and the wall thickness of the heating element is large, the temperature difference between the surface of the heating element and the center is large, resulting in greater thermal stress.

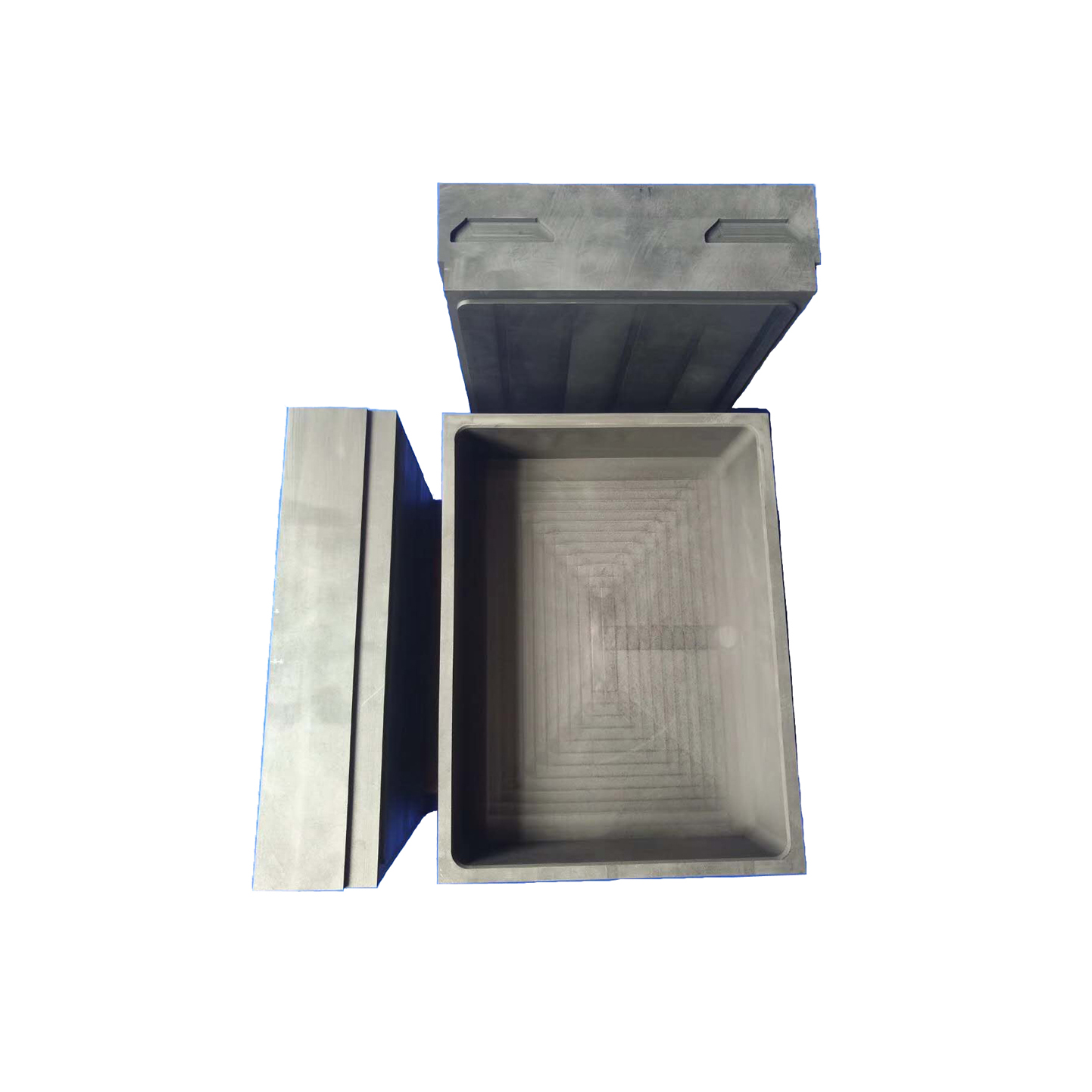

Although the resistivity of graphite is relatively large, in order to increase the strength of the heating element, its side wall should have a certain thickness. Therefore, the total resistance of the heating element is very low and varies with different batches of materials. Need to be equipped with a low-voltage, high-current transformer. Graphite has high mechanical strength, high thermal conductivity and low thermal expansion coefficient. Therefore, it has good thermal shock resistance and can reduce the appearance of cracks at high temperatures.

Optimized design of graphite heater

The researchers conducted a comparative analysis of the simulation calculation results before and after the improvement of the graphite heater structure, and came to the following conclusions:

(1) After the structure of the graphite heater is improved, the uniformity of the temperature field in the graphite cylinder is significantly improved.

(2) After the structure of the graphite heater is improved, the low temperature of the sintered product near the graphite cylinder door has been greatly improved.

After the improvement, the temperature difference between the sintered product near the graphite cylinder door and other positions is small, which improves the uniformity of the surface temperature of the sintered product in the entire furnace, which plays an important role in ensuring the quality of the sintered product in the entire furnace.

(3) After the structure of the graphite heater is improved, although the surface temperature of the sintered product still presents a distribution of high outside and low inside, the highest temperature area is no longer the top and middle sintered product. This is useful for improving the surface of the sintered product near the furnace door. The temperature plays an important role, greatly reducing the influence caused by the absence of heating elements at the furnace door, and improving the uniformity of the surface temperature of the sintered products in the entire furnace.