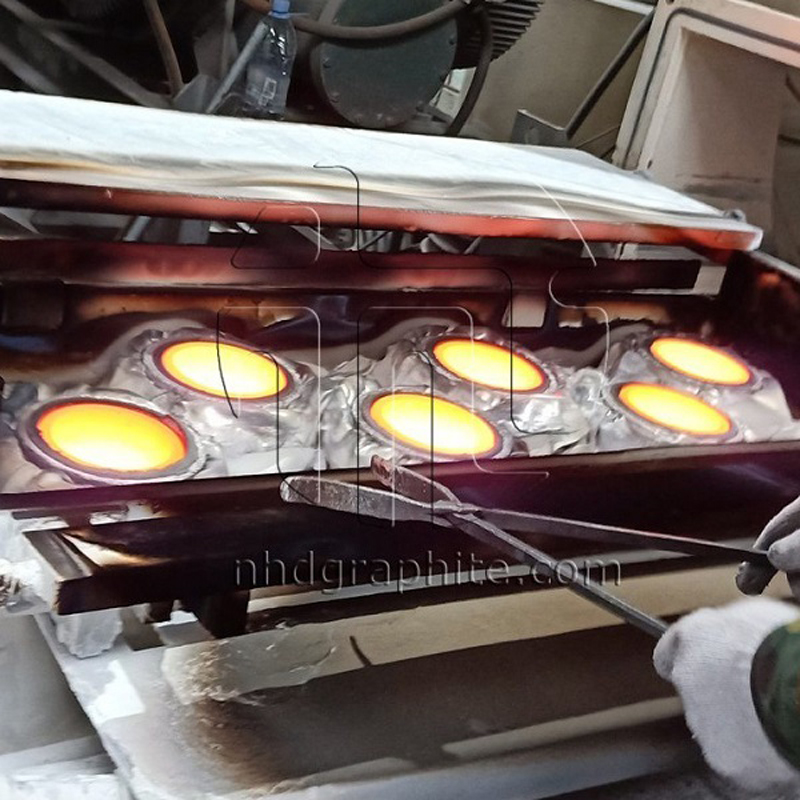

1. Exothermic welding

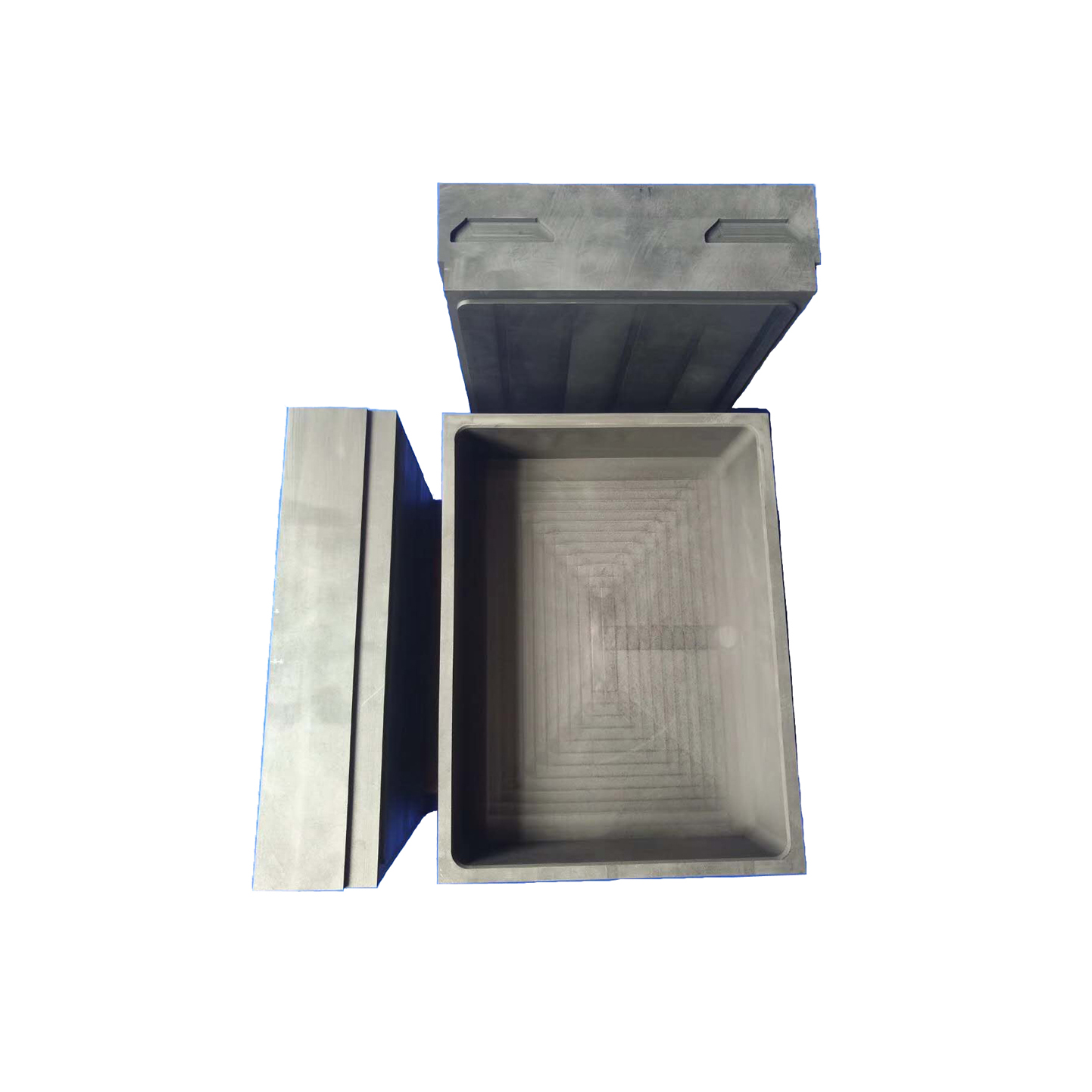

Exothermic welding is a simple, high-efficiency, and high-quality metal joining process. It uses the chemical reaction heat of metal compounds as a heat source, and directly or indirectly heats the overheated (reduced) molten metal to work in a special graphite mold. A welded joint of a certain shape and size is formed in the cavity to meet the engineering requirements. At present, exothermic welding has generally replaced the previous mechanical connection method between metals.

2. Application fields of exothermic welding

1. Lightning protection, grounding and surge protection.

2. Electrical equipment grounding engineering treatment.

3. Petrochemical engineering construction.

4. Construction of railways, highways, and airports.

5. Intelligent building construction.

6. Cathodic corrosion protection.

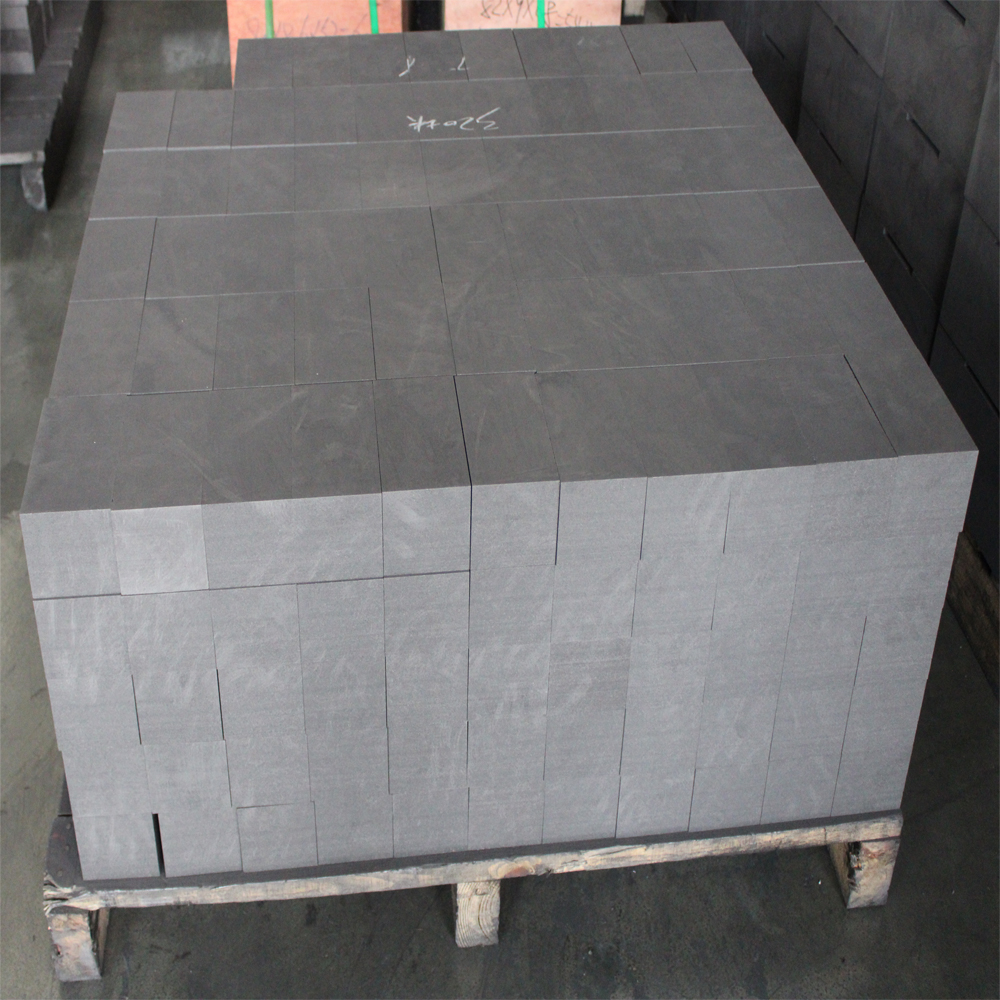

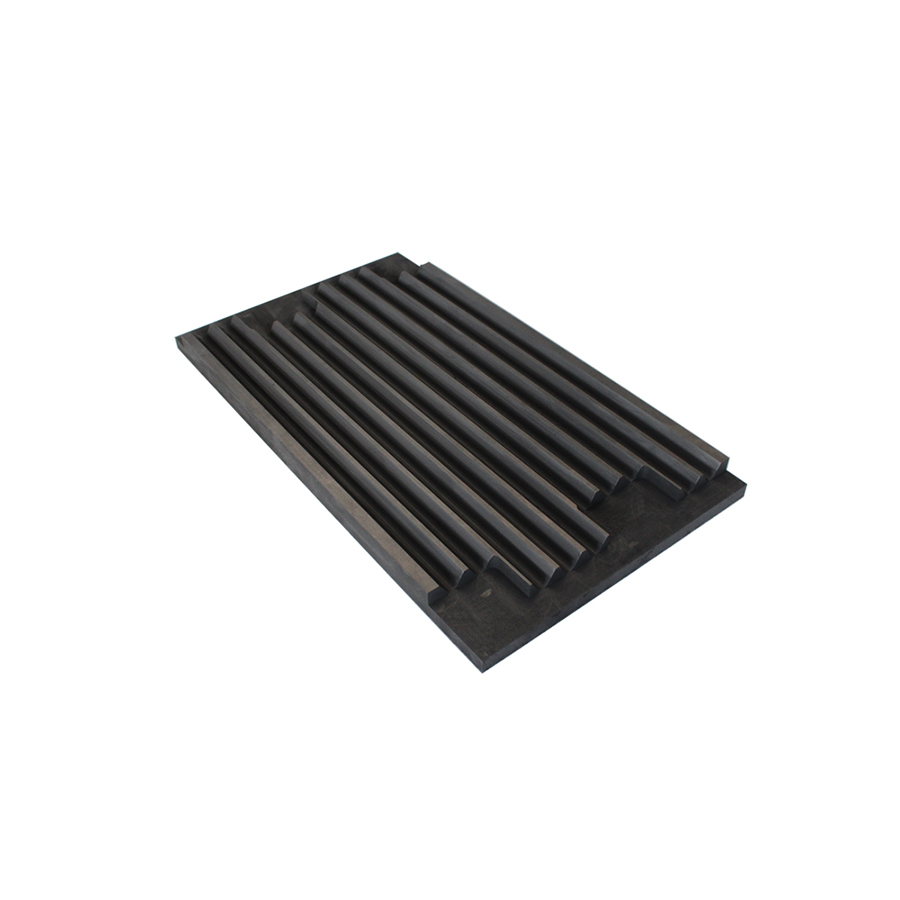

3. Processing graphite block (semi-finished product)

Jiangxi Ningheda New Material Co., Ltd. is a manufacturer specializing in graphite finishing, with advanced processing technology and strong processing capabilities. It is widely praised by customers at home and abroad. The graphite products processed by our company have been unanimously recognized by customers. In response to the requirements of the majority of exothermic welding customers, our company can also process semi-finished graphite blocks for customers, which greatly shortens the delivery time of customers.

Grade: NX82

Grain size(≤): 0.8mm Bulk Density(≥): 1.72g/cm3 Ash (≤): 0.3% Specific Resistance ≤8.5μΩM Compressive Strength ≥35MPa Flexural Strength ≥13.5MPa Coefficient of Thermal Expansion ≤2.2×10-6/℃Grade: NX603 Grain Size(≤): 25μm Bulk Density(≥): 1.80g/cm3 Compressive Strength(≥): 60MPa Flexural Strength(≥): 30MPa Porosity(≤): 17% Specific Resistance(≤): 12μΩm Ash Content(≤): 600ppm Shore Hardness: 50 Coefficient of Thermal Expansion(≤): 5×10-6/℃